Choosing the right printing technology is essential for running a profitable printing business. As print-on-demand continues to grow, thousands of businesses are generating significant income by selecting the right equipment from the start.

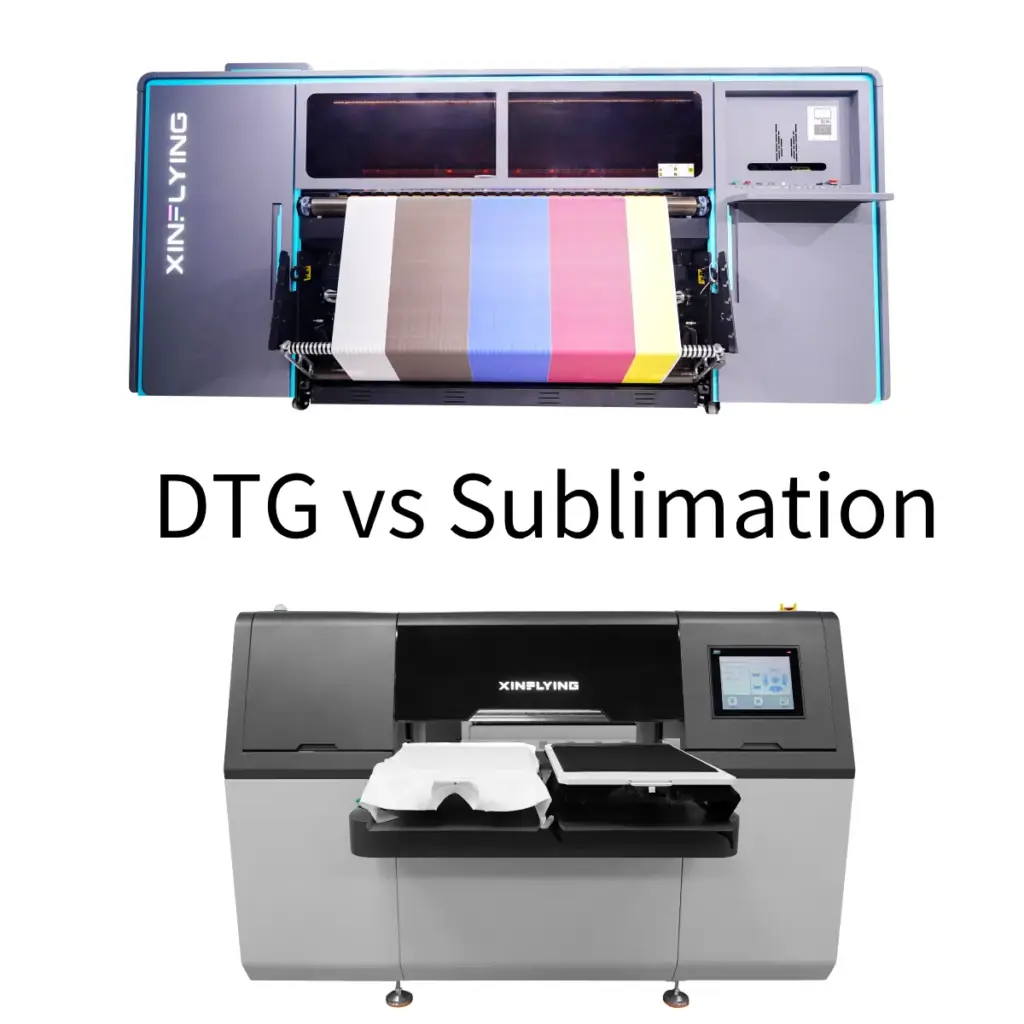

Among the most debated technologies are sublimationstryk og DTG (Direkte-til-garment) trykning. Both are known for excellent print quality, but each serves different materials, workflows, and business needs. Så, which option is best for your printing goals?

This guide breaks down the differences between sublimation and DTG printing—quality, koste, Kompatibilitet, holdbarhed, and more—so you can make an informed long-term decision.

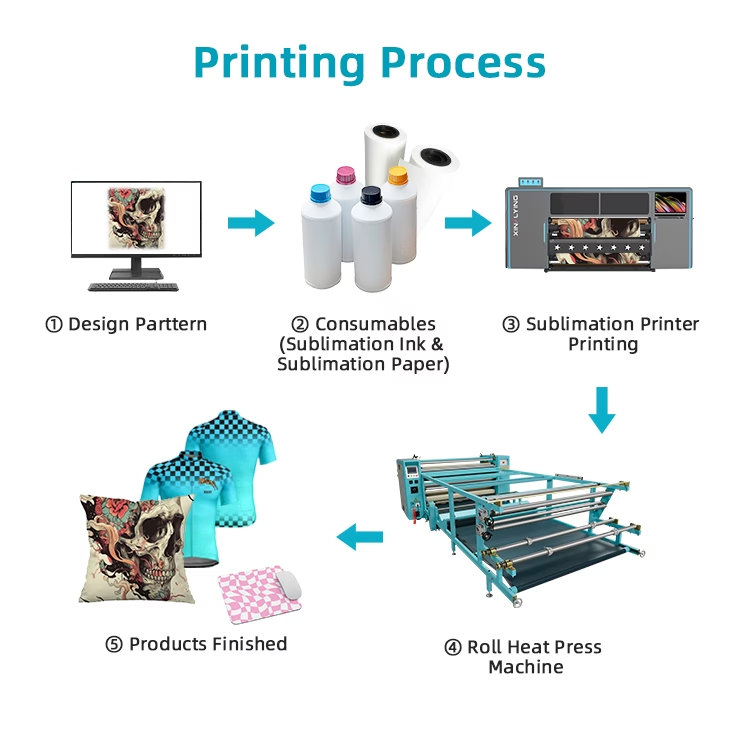

Hvad er sublimeringsprint?

Sublimation printing uses controlled heat and pressure to transform solid dye into gas, bonding it directly into polyester fibers or polymer-coated surfaces. The process starts with a sublimation printer that prints designs onto special sublimation paper using sublimation ink.

Because the ink fuses with the material, the print becomes part of the fabric—meaning it doesn’t crack, skræl, eller falme. Sublimation is ideal for promotional products, sportsbeklædning, and print-on-demand textiles.

How Sublimation Printing Works

- Create the design using graphic design software.

- Print the mirrored artwork onto sublimation paper using sublimation ink.

- Position the paper on the product and secure it with heat-resistant tape.

- Apply heat and pressure using a heat press—this turns the ink into gas and permanently bonds it to the material.

- Allow the product to cool, then peel the paper to reveal a permanent, vibrant print.

Pros of Sublimation

- Produces vivid, long-lasting colors

- Ink becomes part of the fabric—no cracking or peeling

- Smooth, seamless finish with no raised texture

- Excellent for photographic and full-color designs

- Works on many products: krus, tumblere, tøj, indretning, osv.

Cons of Sublimation

- Only compatible with polyester fabrics or polymer-coated items

- Does not work on 100% bomuld

- Limited to light or white materials

- Equipment and consumables can be costly

- Production speed can slow due to heat-transfer steps

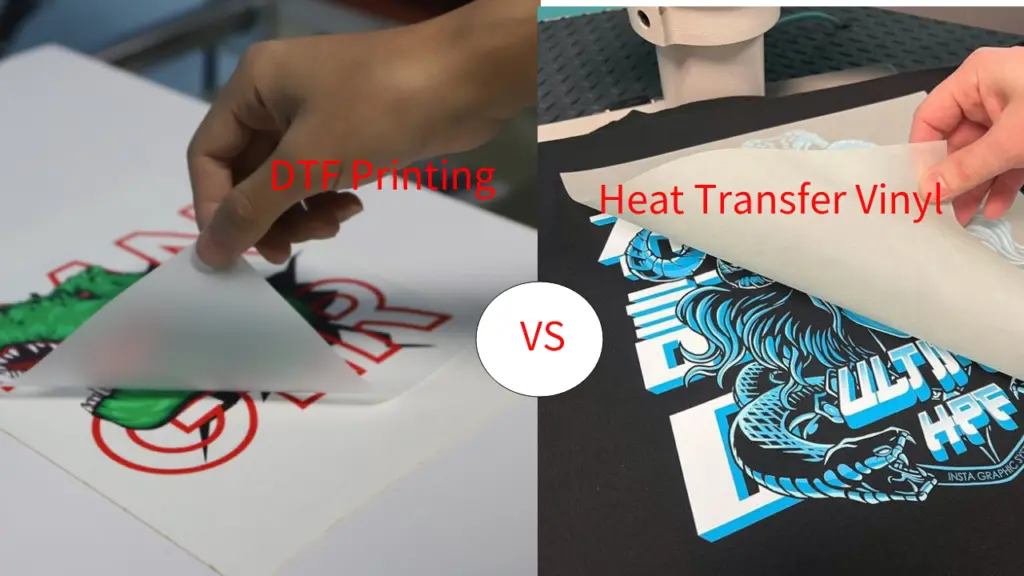

Hvad er DTG -udskrivning?

DTG (Direkte til beklædning) printing functions like an inkjet printer, but prints directly onto fabric. The ink bonds with a pre-treated garment to create highly detailed, soft prints. DTG is ideal for intricate designs, photo prints, and small-batch orders.

Unlike sublimation, DTG works best on natural fibers—especially cotton.

How DTG Printing Works

- Pre-treat the garment to ensure proper ink bonding.

- Prepare the artwork using design or RIP software.

- Print directly onto the garment using white and colored inks.

- Cure the ink using a heat press or built-in curing unit.

- Final product is ready with a soft, detailed print.

Pros of DTG Printing

- Excellent for cotton and natural fiber fabrics

- Highly detailed, colorful prints—even on dark garments

- Fast production and simple workflow

- Ideal for small-quantity or custom orders

Cons of DTG Printing

- Prints sit on the fabric surface and may fade over time

- Requires fabric pre-treatment

- Less durable compared to sublimation on polyester

- Colors may be less vibrant on dark or heavily textured fabrics

DTG vs. Sublimering: Key Differences

1. Stofkompatibilitet

- Sublimering: Polyester, polyblandinger, polymer-coated products

- DTG: Cotton and cotton-blend fabrics

2. Udskriftskvalitet

- Sublimering: Ultra-vibrant, glat, and permanently infused into the material

- DTG: Highly detailed but may appear less vibrant on dark or textured garments

3. Setup Costs

- DTG: Higher initial investment but fewer recurring consumable costs

- Sublimering: Lower equipment cost but requires sublimation ink & paper long-term

4. Running Cost

- DTG: $0.50–$3.50 per print depending on color and complexity

- Sublimering: More cost-effective for large batches and all-over prints

5. Produktionshastighed

- DTG: Faster for ready-made garments, but requires pre-treatment

- Sublimering: Quick printing but longer workflow for full-fabric designs

6. Holdbarhed

- Sublimering: Extremely durable—becomes part of the fabric

- DTG: Good quality but may fade or crack over time

7. Environmental Impact

- DTG: Uses water-based inks, miljøvenlig; pre-treatments vary

- Sublimering: Water-based dyes but requires high energy for heat pressing

| Kategori | DTG udskrivning | Sublimationstryk |

|---|---|---|

| Materialekompatibilitet | Best for 100% bomuld & naturlige fibre | Only works on polyester or polymer-coated items |

| Udskriftskvalitet | High detail; great for complex designs | Extremely vibrant; photo-realistic on polyester |

| Setup Cost | Højere indledende investering | Lower setup cost |

| Running Cost | Higher per-print cost (blæk + pretreatment) | Lower per-print cost, especially for bulk |

| Produktionshastighed | Fast for small orders; pretreatment required | Fast printing; slower for full fabric production |

| Holdbarhed | God, but can fade/peel over time | Excellent; fused into fibers, won’t crack |

| Environmental Impact | Water-based inks but pretreatment chemicals involved | Eco-friendly inks; depends on heat energy use |

| Bedst til | Small–medium orders, cotton apparel, detailed artwork | Large orders, polyester garments, sportsbeklædning, promo items |

Should You Choose DTG or Sublimation?

Choose DTG if:

- You work with 100% bomuld

- You need highly detailed or colorful designs

- You handle small or custom orders

- You prefer minimal setup and fast production

Choose Sublimation if:

- You print on polyester or synthetic fabrics

- You need holdbar, permanent, vibrant results

- You produce masseordrer

- You are a startup with scalable production needs

I sidste ende, the best choice depends on your business model, product range, and customer demand.

Konklusion

Both sublimation and DTG printing offer excellent results—but for different purposes.

- DTG is best for cotton garments, intricate designs, and small to medium orders.

- Sublimering is ideal for polyester materials, levende farver, and high-volume production.

No matter which technology you choose, Xinflyvning provides professional, pålidelig, and cost-effective printing solutions to support your business growth.

Contact Xinflying today to explore printers that deliver exceptional performance, outstanding durability, and unbeatable value for your print-on-demand business.