Produkthøjdepunkter:

1.Wide-Format DTF Printing Capability

Large printing width supports oversized graphics, gang sheets, and batch production—ideal for bulk DTF orders and efficient material usage.

2.Broad Fabric Compatibility

Suitable for nylon, kemisk fiber, bomuld, læder, og mere, delivering stable adhesion and consistent print quality across different materials.

3.High-Quality DTF Output

Ensures rich color performance, clear details, and strong ink bonding. When used with Xinflying DTF ink and powder, prints remain durable and washable.

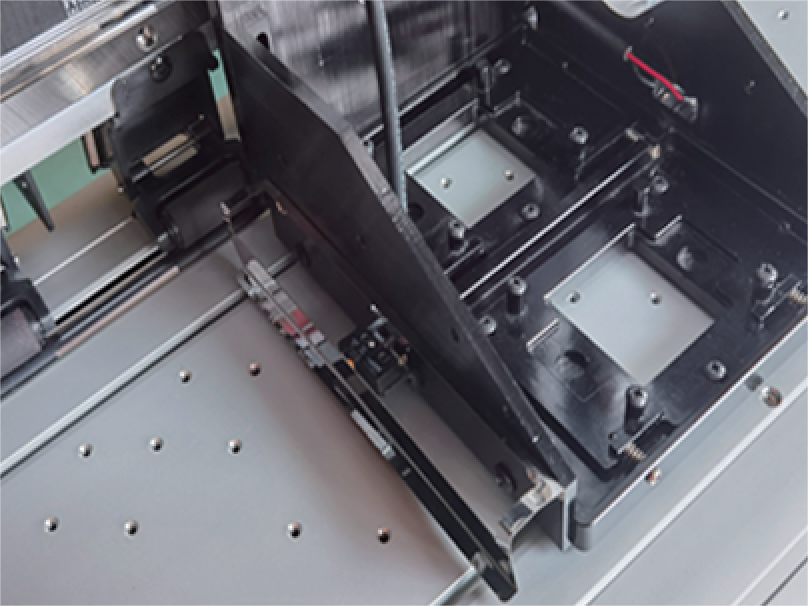

4.Industrial-Grade Structure

Solid machine construction combined with a stable ink delivery system enables smooth operation and reliable performance for long-term production.

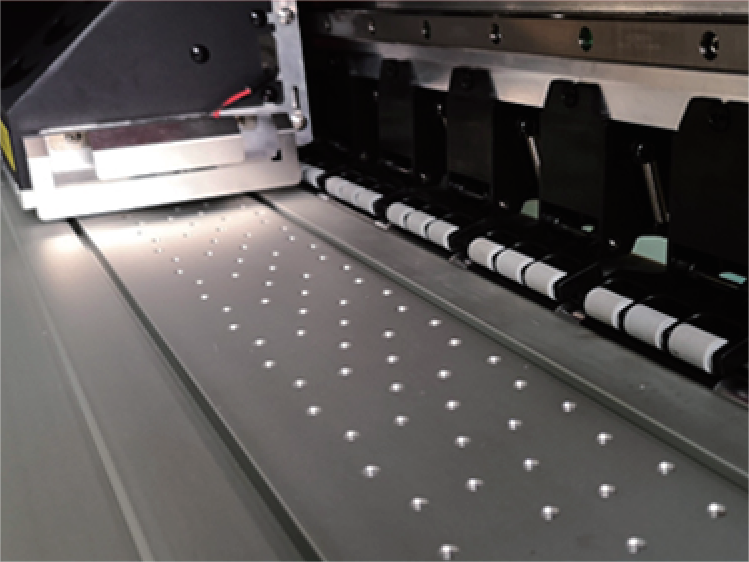

This dtf printer is equipped with a durable silver guide rail designed for smooth and stable carriage movement. It enhances printing precision, reduces vibration, and ensures long-term reliability even during high-speed production.

Engineered for professional DTF printing, the machine features high-performance components, efficient workflow design, and superior output quality. Every detail is optimized to deliver consistent results for business-level production.

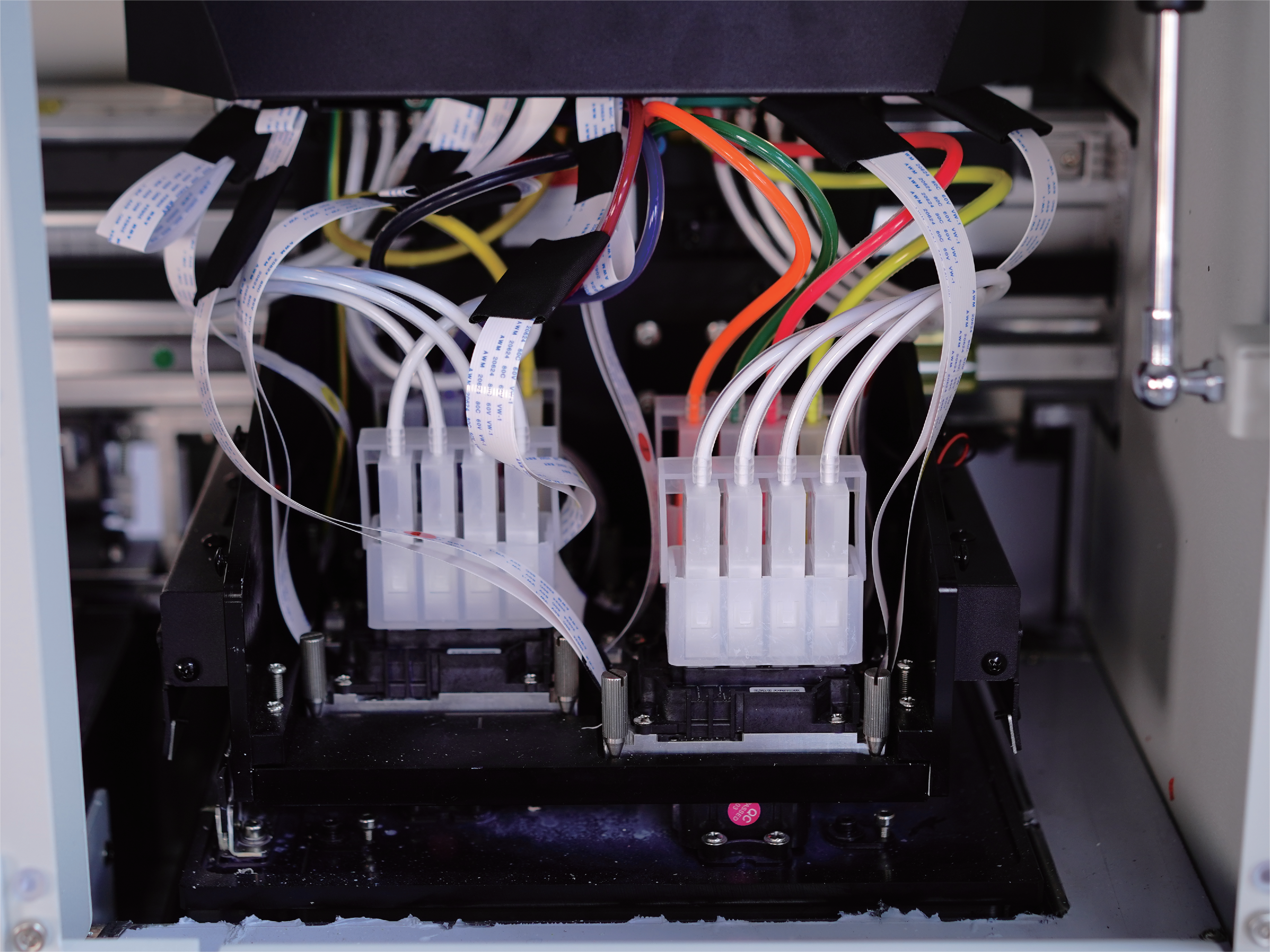

The printer uses a CMYK+W color configuration, delivering vibrant, nøjagtig, and high-opacity prints. A dedicated white ink channel provides strong coverage for dark fabrics, ensuring crisp and vivid image quality.

Built-in anti-collision sensors protect the printhead by detecting obstructions during printing. This prevents accidental damage, reducerer nedetid, and ensures stable, worry-free operation in busy production environments.Industrial-grade internal components ensure durability, stabilitet, and consistent output for DTF printer manufacturers and apparel businesses.

| Model | I3200-A1 |

|---|---|

| Blæktype | AQ blæk |

| Maks. antal farveblæk | 4 farver |

| Antal dyse | 3200 |

| Dysestigning/dyserække | 1/300 tommer |

| Dyserækker | 8 rækker |

| Dyse opløsning | 300npi/1 kolonne 600npi/2 kolonner |

| Effektiv udskriftsbredde | 33.8 mm (1.33 tommer) |

| Dimensioner(LxBxH) | 69.1 x 59.4 x 35.6 mm |

| Vægt | 82g |

| Model | C804 |

|---|---|

| Printhoved og antal | 4PCS I3200-A1 |

| Udskrivningshastighed | 4Passere:25m²/h 6Pass:18m²/h |

| Udskriftsbredde | 32" |

| Medietype | DTF kæledyrsfilm |

| RIP-software | Standard med Printfactory,maintop, RIN,Fotoprint,CAD link til Valgfrit |

| Temperatur | 20-30 °C |

| Fugtighed | 45-65% |

| Magt | 1.1KW |

| Maskinens dimension | L1950*W820*H1680MM |

| Pakkedimension | L2135*W875*H760MM |

| Nettovægt | 150KG |

| Bruttovægt | 230KG |

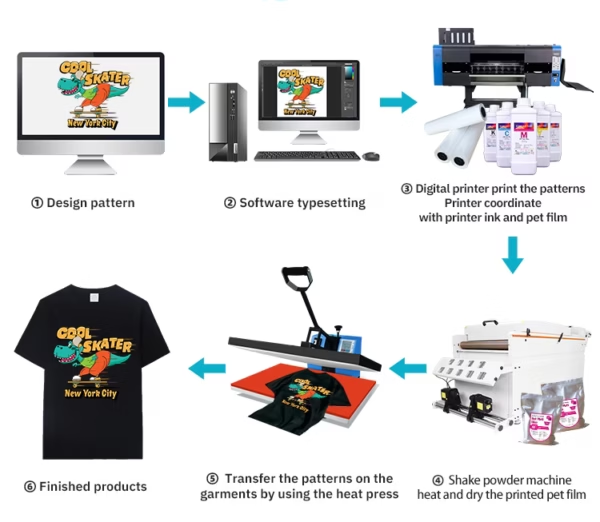

Brug forskellige designsoftware til at designe spotfarvekanaler.

Brug RIP-software, farve + staffagefarven er RIP ud.

DTF fluorescerende print, støvning, tørring hele processen med integreret operation behandling, automatisk optræk.

Den trykte PET-film vil blive skåret manuelt eller skåret af en skæremaskine, og derefter trykkes med varmt tryk, og filmen vil være færdig efter rivning.

Q1: What production capacity does this printer support?

EN: Suitable for large commercial DTF printing factories.

Q2: Are consumables compatible with other DTF machines?

EN: Ja, uses industry-standard DTF consumables.

Q3: Can it run continuously?

EN: Ja, industrial-grade components support long operation.

Q4: What support is included?

EN: Garanti, spare parts, and remote technical assistance.

Udskriftsbredde

Produktivitet

Printhoved

Dimension

Udskriftsbredde

Produktivitet

Printhoved

Dimension

Udskriftsbredde

Produktivitet

Printhoved

Dimension

Lær mere om vores DTF, DTG, sublimationsprintere, og forbrugsvarer.

Lær mere om vores DTF, DTG, sublimationsprintere og forbrugsvarer.