Untuk memastikan DTF Anda (Langsung ke Film) printer tetap dalam kondisi optimal dan bertahan lebih lama, Ikuti tips pemeliharaan dan praktik terbaik ini. Proper care will reduce downtime, prevent clogs, and extend the printer’s lifespan.

1. Regular Cleaning & Pemeliharaan

Print Head Maintenance

Pembersihan Harian:

Run nozzle checks and perform head cleanings (using printer software) to prevent ink clogs.

Use compatible cleaning fluids (not alcohol) for manual wiping if needed.

Weekly Deep Cleaning:

Remove excess ink around the head with a lint-free swab and cleaning solution.

Flush the capping station to prevent dried ink buildup.

Ink System Care

Keep ink cartridges/refillable tanks full to avoid air bubbles.

Shake white ink bottles before refilling to prevent pigment settling.

Use high-quality ink to reduce clogs and nozzle issues.

Wiper & Capping Station

Clean the wiper blade and capping station weekly to prevent dried ink buildup.

Replace worn-out wiper blades and dampers as needed.

2. Penyimpanan yang Tepat & Environment Control

Ideal Printing Conditions

Suhu: Keep the printer in a 15-25°C (59-77°F) environment.

Kelembaban: Maintain 40-60% humidity to prevent ink drying or clogging.

Avoid Dust & Sunlight:Keep the printer in a clean, shaded area away from direct sunlight.

Long-Term Storage (If Not Used for Weeks)

Run a deep cleaning cycle before storage.

Seal ink cartridges and cover the printer to prevent dust buildup.

For white ink printers, consider flushing the system with a storage solution.

3. Preventing Common Issues

White Ink Settling & Clogging

Stir or shake white ink daily before printing.

Run a short print job or nozzle check if the printer sits idle for more than a day.

Use agitators (if available) in white ink tanks to prevent settling.

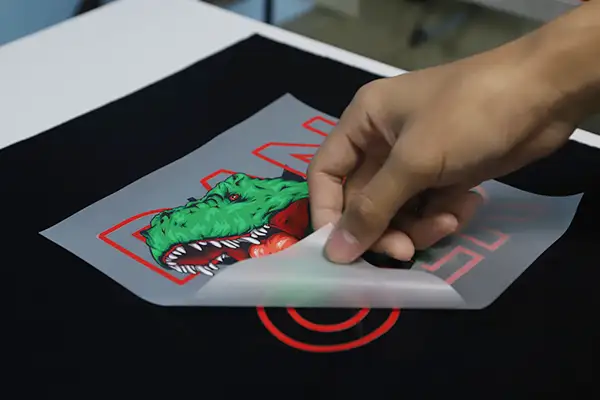

Film Jams & Feeding Problems

Use high-quality PET film (avoid wrinkled or static-prone films).

Adjust feed tension if the film slips or jams.

Clean feed rollers regularly to ensure smooth movement.

4. Firmware & Software Updates

Update printer firmware regularly for bug fixes and performance improvements.

Use recommended RIP software (MISALNYA., AccuRIP, Wasatch, Epson Edge) for stable printing.

5. Proper Handling & Usage

Avoid Forceful Adjustments:Never manually move the print head; use printer controls.

Use Genuine/Compatible Parts:Cheap third-party inks or parts can damage the printer.

Power Down Properly: Always shut down via the printer’s menu to allow proper head parking.

6. Extending Print Head Life

Cetak secara teratur (at least every 2-3 hari) to prevent ink drying.

Avoid Excessive Cleaning Cycles(can waste ink and wear out the head).

Use a Head Protection Film (if available) to reduce wear.

7. Post-Printing Care

Clean Excess Powder:After applying DTF adhesive powder, remove residue from the printer to prevent buildup.

Check Curing Process:Ensure proper heat settings to avoid excessive heat exposure to printer parts.

Final Tips for Longevity

Sehari-hari:Nozzle checks, wipe down printer.

WeeklyDeep clean heads, check ink levels.

Monthly: Inspect belts, clean feed rollers, update firmware.

Yearly:Replace worn parts (dampers, wiper, maintenance cartridges).

Dengan mengikuti langkah-langkah ini, your DTF printer will stay reliable, produce high-quality prints, and last significantly longer.