Avere domande?

Migliori stampanti DTF per la tua attività

Inizia a generare entrate gravi con veloce, Stampa di trasferimento di livello commerciale a un prezzo accessibile.

Produzione ad alta velocità per la massima efficienza

Proprietà e funzionamento a prezzi accessibili

I trasferimenti sono durevoli come la stampa dello schermo

Le stampe offrono un elevazione e recupero eccellenti

Compatibile con qualsiasi tessuto

Tempo di stampa di calore sotto 15 secondi

I nostri prodotti sono dotati di componenti di fiducia dai migliori marchi.

“Il tuo team ha reso il processo di ordinazione senza soluzione di continuità. Sono fiducioso di sapere che ho supporto mentre inizio questo nuovo viaggio, Ed è bello sapere che hai un magazzino proprio qui in California!”

Hannah

Siamo il più grande fornitore DTF negli Stati Uniti.

- California Warehouse

- Consegna efficiente

- 24/7 Supporto post-vendita

- Prezzi competitivi

- Prodotti di qualità

- Personalizzazione flessibile

Adatto per i seguenti tessuti e prodotti

- Poliestere

- Cotone pettinato

- Anello filato filato

- Cotone organico

- Tessuti miscelati

- Tri-silenzia

- E altro!

- Magliette

- Freddo

- Felpe

- Tag del marchio

- Zaini

- Dopo

- Bandiere

- Uniformi sportivi

- Borse tote

- Cappelli

- Pulsanti

- Shorts in esecuzione

- Pantaloni della tuta

- E molto di più!

Le stampanti DTF ideali per le tue esigenze

DTF XF-450Pro

Stampante commerciale ideale per la produzione 500 T-shirt frontali piene al giorno.

- Dimensioni: 68.3″L*42.5″ W x 52.4″ D

- Velocità: 90X Transfer/ora della maglietta frontale completa/ora

- Applicazione adesiva: Completa la produzione in linea con applicazione

e asciugatrice - Software: Standard con printfactory & maintop , Stampa fotografica & Cadlink per ottinale

- Colore: C M Y K + W

- Inchiostro & Media: Il pacchetto include il kit di partenza

- Formazione & supporto

- 1 anno di garanzia: (Compreso 6 Mo. STAMPA GARANZIA PERSONA)

- Peso lordo: 200KG

- Tensione di velocità: 110V/220 V

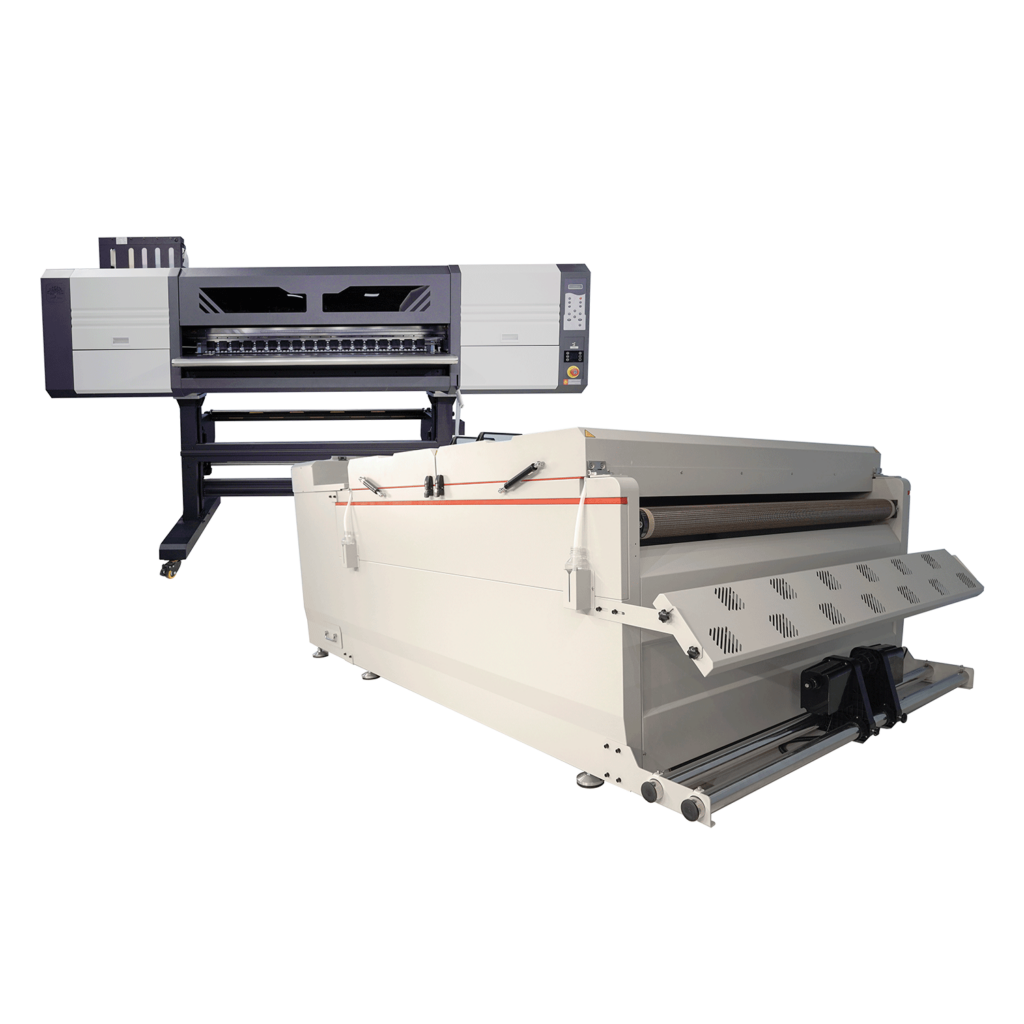

DTF C602+H650

Stampante commerciale ideale per la produzione 600 T-shirt frontali piene al giorno.

- Dimensioni: 65.4″L*29.6″ W x 63.8″ D

- Velocità: 100X Transfer/ora della maglietta frontale completa/ora

- Applicazione adesiva: Completa la produzione in linea con applicazione

e asciugatrice - Software: Standard con printfactory, Principale , RENO, Stampa fotografica, Cadlink per ottinale

- Colore: C M Y K + W(5 Colore)

- Inchiostro & Media: Il pacchetto include il kit di partenza

- Formazione & supporto

- 1 anno di garanzia: (Compreso 6 Mo. STAMPA GARANZIA PERSONA)

- Peso lordo: 200KG

- Tensione di velocità: 110V/220 V

DTF L1208+H1300

Stampante commerciale ideale per la produzione 6000 T-shirt frontali piene al giorno.

- Dimensioni: 112.6″L*36″ W X 74.41″ D

- Velocità: 600X Transfer/ora della maglietta frontale completa/ora

- Applicazione adesiva: Completa la produzione in linea con applicazione

e asciugatrice - Software: Standard con printfactory, Principale , RENO, Stampa fotografica, Cadlink per ottinale

- Inchiostro & Media: Il pacchetto include il kit di partenza

- Formazione & supporto

- 1 anno di garanzia: (Compreso 6 Mo. STAMPA GARANZIA PERSONA)

- Peso lordo: 488KG

- Tensione di velocità: 110V/220 V

Come funziona la stampa DTF?

Le nostre stampanti DTF creano fogli di trasferimento digitale vibranti, Perfetto per tutto, dalle etichette a maglietta singola ai disegni a grandezza naturale. Utilizzando un film per animali domestici spesso 0,75 mm per una qualità di trasferimento superiore, Le nostre stampanti sono alimentate e progettate per un processo di buccia fredda. Il film traslucido garantisce un facile allineamento durante la pressione di calore.

“Il team Xinflying è stato incredibilmente utile nel trovare la macchina perfetta per la mia attività. Hanno risposto prontamente a tutte le mie domande, E il loro servizio clienti era eccezionale. Consiglio vivamente XinFlying per tutte le tue esigenze aziendali.”

Dimostrare la stampa DTF può aumentare i tuoi profitti!

Le stampanti DTF offrono un modo economico per produrre prodotti di alta qualità che offrono forti rendimenti per la tua attività.Abbattiamo un rapido lavoro di maglietta per illustrare come può essere redditizia la stampa DTF:

Costi di produzione:

- Inchiostro, polvere & film: $1.50 per maglietta (davanti e dietro)

- Camicia vuota: $5.50

- Costo totale per maglietta: $7.00

Dettagli di lavoro:

- Numero di camicie: 60

- Tempo di stampa: 30 min. per 120 trasferimenti + 7 min. Tempo di asciugatura

- Costo del lavoro totale: $420.00

Valore lavorativo:

- Valore al dettaglio: $1,400

- Profitto: $980.00

Perché Xinflying si trova sopra la competizione?

Supporto senza pari per il tuo successo

Unisciti ai ranghi dei principali marchi globali che offrono prodotti personalizzati e personalizzati, con il nostro supporto completo!

Guida di esperti: I nostri esperti consultivi ti aiutano a selezionare la stampante e gli accessori perfetti su misura per le esigenze aziendali.

Inizio rapido: Avvicinati e funzionare con una macchina pronta per la stampa e una formazione online gratuita, assicurandoti di iniziare a produrre più velocemente che mai.

Supporto dedicato: I nostri tecnici qualificati sono sempre disponibili a rispondere alle tue domande, dall'impostazione e dall'operazione alle applicazioni avanzate.

Hai bisogno di aiuto con la formazione o avere domande generali sulle stampanti DTF?

La differenza tra DTF e stampa sullo schermo

La stampa dello schermo è stata a lungo una pietra miliare della redditività e della produzione nel settore della personalizzazione. Tuttavia, Man mano che il settore avanza e le aspettative dei clienti crescono, La stampa dello schermo affronta diverse sfide. Uno degli ostacoli più significativi oggi è la difficoltà nell'assunzione e nella formazione del personale per le strutture di produzione. Il processo di formazione per la stampa a schermo è esteso, Spesso impiegando mesi per padroneggiare, Ed è costoso. Ciò ha portato molti negozi di tipografia a passare alla tecnologia DTF, che consente un onboarding più rapido e una produzione più veloce.

La stampa sullo schermo comporta anche numerosi passaggi complessi e spesso si traduce in considerevoli rifiuti. L'uso di sostanze chimiche e lo smaltimento di materiali pericolosi non solo aumenta il costo, ma è anche contrario alla crescente enfasi sulla sostenibilità ambientale. La tecnologia DTF affronta questi problemi con rifiuti minimi e riduce significativamente la dipendenza da sostanze dannose.

Vantaggi di DTF su Schermate Printing

- Tempi di configurazione rapidi

- Processi di produzione e pressenza più semplici

- Avviare facilmente un'attività di trasferimento all'ingrosso

- Non è necessario che gli schermi, pulito, lavare, o riutilizzo

- Riduzione dei rifiuti

- Tutti i colori stampati in un unico passaggio

- Immagini digitali a colori

- Durabilità di lavaggio e allungamento superiore

La differenza tra DTF e taglio del vinile

Vinile a trasferimento termico (HTV) è ampiamente utilizzato per la personalizzazione dell'abbigliamento grazie al suo costo di accesso economico. Tuttavia, viene fornito con alcune sfide significative. Due delle maggiori frustrazioni per gli imprenditori sono il lavoro manuale coinvolto nel diserbo e la complessità dei progetti multicolori. Ogni volta che il materiale viene elaborato tramite un plotter di taglio, Il vinile in eccesso deve essere meticolosamente rimosso prima che il trasferimento possa essere completato. Quando si lavora con design multi-colore, Questo processo deve essere ripetuto per ogni colore, aumentando significativamente il tempo e lo sforzo richiesti per ogni prodotto finale.

Un'alternativa popolare sta usando una stampa & Sistema di taglio, che aggiunge una capacità di stampa digitale al taglio del vinile. Tuttavia, Questo non elimina la necessità di disertare il prodotto post-stampa. Questo processo è spesso lento e costoso, Condurre molti imprenditori a cercare aggiornamenti tecnologici prima piuttosto che dopo. Mentre stampa & I sistemi tagliati offrono una grande versatilità, Non sono ideali per l'alta velocità, ambienti ad alta produzione.

Vantaggi del DTF sul taglio del vinile

- Tutti i colori in una singola stampa

- Stampe a tutto digitale per grafica sia raster e vettoriale

- Stampe pronte per trasferimento senza tempo di mascheramento o asciugatura prima di premere

- Non è necessario diserbirsi

- Migliore sensazione e lavabilità delle mani rispetto alla stampa & Taglio

- Tempi di produzione significativamente più veloci

- Riduzione dei rifiuti e minori costi di produzione

La differenza tra la stampa DTF e DTG

Uno dei principali vantaggi di DTF su macchine DTG di fascia alta è l'efficienza della produzione di più capi in parallelo. Con dtg, L'operatore deve rimanere accanto alla macchina, Garantire che ogni camicia sia perfettamente piatta, che può comportare tempi di inattività significativi in attesa che la stampa sia completata.

DTF funziona in modo diverso, Poiché le funzioni di stampa e applicazione sono separate. Ciò significa che non è necessario portare il capo alla macchina; Invece, È possibile applicare il trasferimento stampato in più capi contemporaneamente, semplificare il processo di produzione.

Inoltre, I trasferimenti DTF sono versatili e possono essere facilmente applicati a aree difficili come i tag, maniche, e indumenti di forma in modo univoco.

Vantaggi della stampa DTF

- Premere i tempi fino a 5 volte più veloce di DTG

- Teste di stampa affidabili, con alcuni modelli che offrono una garanzia di 6 mesi senza precedenti

- Non c'è bisogno di sostanze chimiche pre-trattamento o camicie bagnate

- Non è richiesto il tempo di asciugatura

- Costi inferiori per inchiostro e adesivo rispetto all'inchiostro e al pretrattamento

- Non c'è bisogno di pre-prevedere gli indumenti

- Elaborazione e assemblaggio paralleli efficienti

© 2023 Xinflying Incorporated. Tutti i diritti riservati

Termini e condizioni Informativa sulla privacy