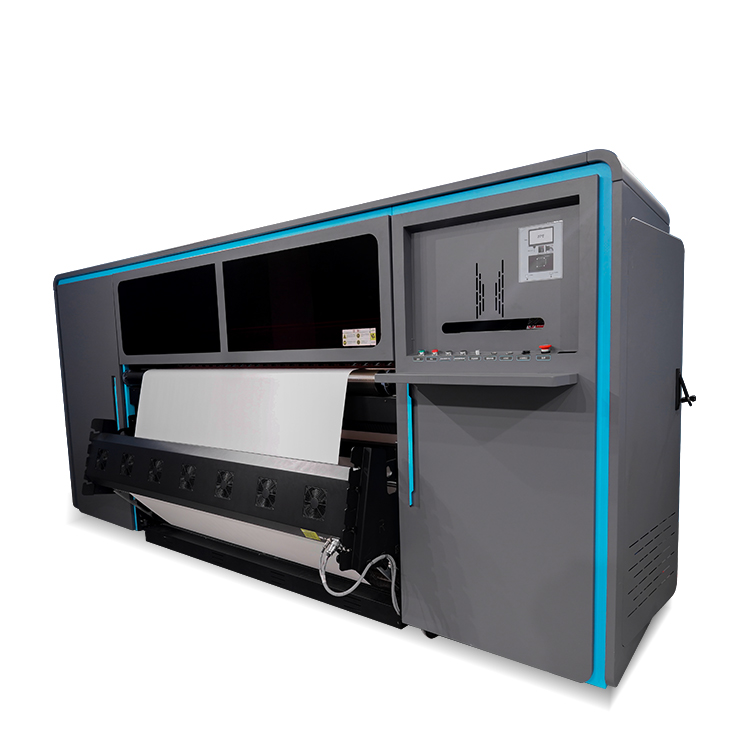

XF-19A15-PRO 15PCS I3200-A1 Sublimation Printers

Parameter

Haupteigenschaften

Intelligent Drying System

Equipped with a fast print and dry system, the temperature can be adjusted in real time depending on the actual situation during printing. It is synchronized with printing, energy saving, and emission reduction.

Anti-collision Frame

The nozzle can be automatically positioned based on the printing consumable. Anti-collision devices are added at both sides, which can offer more comprehensive safety protection for the nozzle.

Japan THK Double Rail

The THK double rail imported from Japan is precise and smooth, which ensures that the printer remains stable, noiseless, unobstructed at any parts and has a longer service life.

Retractable System

Built to large amount and weight of paper, it can feed paper evenly, and have short filling and deflation operation time, allowing uniform stress, smooth, and firm receiving on the paper during printing.

Epson-Druckkopf

| Modell | I3200-A1(Optional 4720) |

|---|---|

| Stücke | 8 |

| Tintentyp | Apös |

| Max. Anzahl der Farbtinten | 8 Farben |

| Anzahl der Düsen | 3200 |

| Düsenabstand/Düsenreihe | 1/300 Zoll |

| Düsenreihen | 8 Reihen |

| Düsenauflösung | 300npi/Zeile 600 npi/2 Reihen 1200 npi/4 Reihen |

| Effektive Druckbreite | 33.8 mm (1.33 Zoll) |

| Maße(LxBxH) | 69.1 X 59.5 X 36.7 mm |

| Gewicht | 78G |

Technischer Parameter für Drucker

| Modell | 5268 |

|---|---|

| Druckgeschwindigkeit | 1 Passieren: 610 qm/h 2 Passieren: 300 qm/h |

| Druckbreite | 1900mm |

| RIP-Software | Standardmäßig bei Printfactory,Maintop Software,RHEIN, Photoprint Software, CADlink for optional |

| Operate System | Windows 11/windows 10 |

| Temperatur / Feuchtigkeit | 18-30 Celsius/35%-65%Rh |

| Druckauflösung | 3200dpi |

| Print File Format | BMP, TIF, JPG, PDF Etc. |

| Stromspannung | 110-220V |

| Bruttogewicht | 1500 KG |

| Paketabmessungen | 4010 X 1180 x 2160mm |

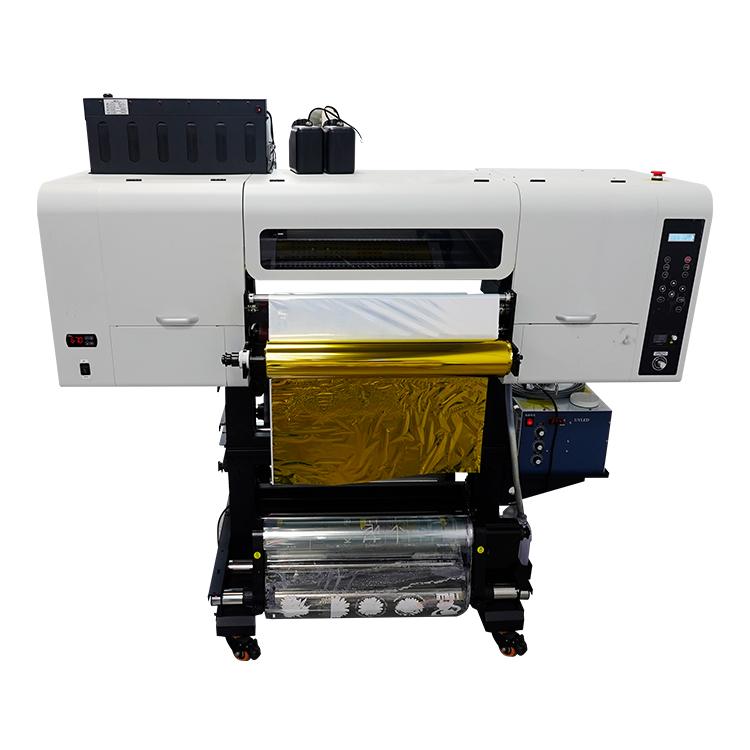

Technische Parameter für Pulverschüttelmaschine

Wie funktioniert es?

Satz am Computer

Satz am Computer

Im Gerät drucken

Im Gerät drucken

Wärmeübertragung

Wärmeübertragung

Finshed Product

Finshed Product