Stoffdruck ist eine Kunst, die sich im Laufe der Jahre dramatisch weiterentwickelt hat, bietet eine Vielzahl von Techniken, um Designs zum Leben zu erwecken. Ob Sie individuelle T-Shirts herstellen, Entwerfen von Stoffen für Mode, oder die Herstellung von Werbeartikeln, Die von Ihnen gewählten Textildrucktechniken können einen erheblichen Unterschied im Endprodukt machen. In diesem Leitfaden wird darauf eingegangen 6 Arten von Stoffdrucktechniken, Erforschung ihrer Prozesse, Anwendungen, Profis, und Nachteile, um Ihnen bei der Auswahl der besten Methode für Ihre Bedürfnisse zu helfen.

Siebdruck

Siebdruck ist eine der ältesten und am weitesten verbreiteten Stoffdrucktechniken. Dabei wird eine Schablone erstellt (oder Bildschirm) und damit werden Tintenschichten auf die Druckoberfläche aufgetragen.

Verfahren

Der Prozess beginnt mit der Erstellung einer Schablone auf einem feinmaschigen Sieb. Anschließend wird die Tinte mit einem Rakel durch das Netz auf den Stoff gedrückt. Jede Farbe im Design erfordert ein separates Sieb und eine separate Tintenschicht, wodurch es für einfache Zwecke geeignet ist, mutige Designs.

Anwendungen

Siebdruck ist ideal für Großaufträge und wird häufig für T-Shirts verwendet, Tragetaschen, und Plakate. Besonders beliebt ist es in der Mode- und Werbebranche.

Vorteile

- Haltbarkeit: Erzeugt langlebige Drucke, die wiederholtem Waschen standhalten.

- Lebendige Farben: Angebote reichhaltig, lebendige Farben, die auffallen.

- Kostengünstig: Wirtschaftlich bei großen Chargen.

Nachteile

- Einrichtungszeit: Erfordert erhebliche Einrichtungszeit, Dies macht es bei kleinen Bestellungen weniger effizient.

- Begrenzte Details: Nicht ideal für Designs mit komplizierten Details oder vielen Farben.

Direkt zum Kleidungsstück (DTG) Drucken

DTG-Druck nutzt Tintenstrahltechnologie, um Designs direkt auf Stoff zu drucken. Stellen Sie sich das wie einen riesigen Tintenstrahldrucker für Kleidung vor.

Verfahren

Der Stoff wird in den DTG-Drucker geladen, Dabei wird Tinte direkt auf die Oberfläche aufgetragen. Die Tinte dringt in die Fasern ein, Dadurch entsteht ein weicher und haltbarer Druck. Diese Methode eignet sich hervorragend für detaillierte und mehrfarbige Designs.

Anwendungen

Perfekt für kleine bis mittlere Bestellungen, Der DTG-Druck wird häufig für individuelle T-Shirts verwendet, insbesondere solche mit komplexen und farbenfrohen Designs.

Vorteile

- Detail und Farbe: Kann hochauflösende Bilder mit einem breiten Farbspektrum drucken.

- Keine Einrichtungskosten: Ideal für Kleinserien und Sonderanfertigungen.

- Weiches Finish: Erzeugt Drucke, die sich weich anfühlen.

Nachteile

- Kosten: Höhere Kosten pro Einheit bei größeren Bestellungen.

- Langsamere Geschwindigkeit: Langsamere Produktionszeiten im Vergleich zum Siebdruck.

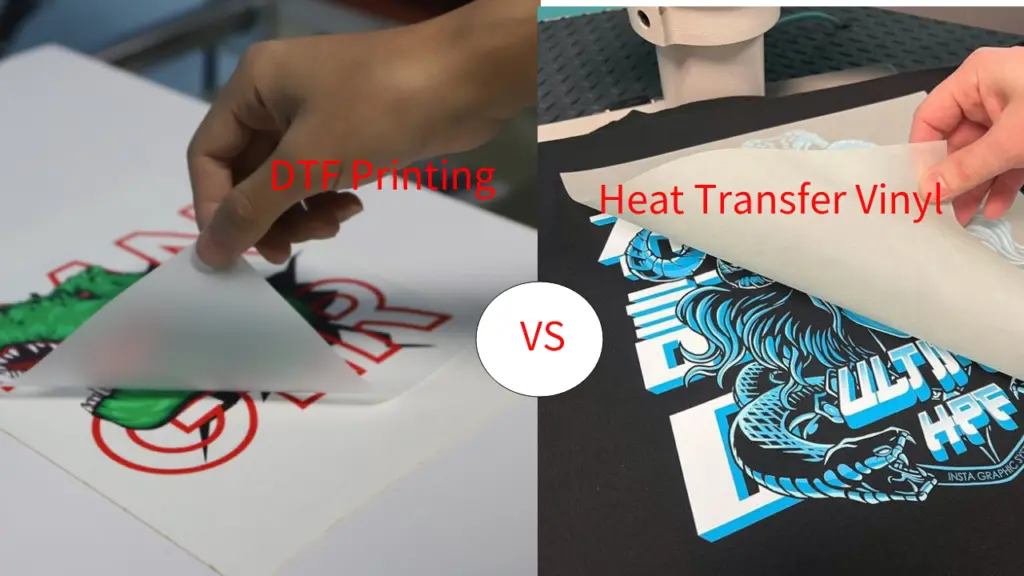

Direkt zum Film (DTF) Drucken

Unter verschiedenen Arten von Stoffdrucktechniken, DTF-Druck zeichnet sich durch seine Vielseitigkeit aus. Beim DTF-Druck wird ein Design auf eine spezielle Folie gedruckt, welches dann mittels Hitze und Klebepulver auf den Stoff übertragen wird.

Verfahren

Die Designs werden mit einem speziellen DTF-Drucker auf eine PET-Folie gedruckt. Die bedruckte Folie ist mit Klebepulver beschichtet, geschmolzen, und dann mit einer Heißpresse auf den Stoff übertragen.

Anwendungen

Der DTF-Druck ist vielseitig, geeignet für verschiedene Stoffe, einschließlich Baumwolle, Polyester, und Mischungen. Es wird häufig für individuelle Bekleidung und Werbeartikel verwendet.

Vorteile

- Vielseitigkeit: Kann auf einer Vielzahl von Materialien drucken.

- Detail: Bewältigt detaillierte und mehrfarbige Designs gut.

- Haltbarkeit: Erzeugt langlebige Drucke, die Rissen und Verblassen widerstehen.

Nachteile

- Komplexität: Erfordert mehrere Schritte und präzise Steuerung.

- Kosten: Die Ersteinrichtung und die Materialien können kostspielig sein.

Sublimationsdruck

Sublimationsdruck nutzt Hitze, um Farbstoff auf den Stoff zu übertragen, Das Ergebnis sind lebendige und dauerhafte Designs.

Verfahren

Das Design wird mit Sublimationstinte auf spezielles Sublimationspapier gedruckt. Durch die Anwendung von Hitze und Druck wird der Farbstoff vom Papier auf den Stoff übertragen, wo es auf molekularer Ebene bindet.

Anwendungen

Bestens geeignet für Polyester- und polymerbeschichtete Stoffe, Der Sublimationsdruck wird häufig für Sportbekleidung verwendet, Flaggen, und individuelle Werbeartikel.

Vorteile

- Lebendige Farben: Erzeugt helles Licht, beschwingt, und dauerhafte Farben.

- Allover-Druck: Ideal für vollflächige Drucke.

- Haltbarkeit: Die Designs sind langlebig und reißen nicht, schälen, oder verblassen.

Nachteile

- Stoffbeschränkungen: Beschränkt auf Polyester- oder Polymerbeschichtete Oberflächen.

- Kosten: Kann aufgrund spezieller Materialien teuer sein.

Pigmentdruck

Beim Pigmentdruck werden pigmentierte Tinten verwendet, die auf den Stofffasern sitzen, anstatt einzusaugen.

Verfahren

Das Design wird mit einem Drucker, der mit pigmentierten Tinten ausgestattet ist, direkt auf den Stoff gedruckt. Nach dem Drucken, Der Stoff wird normalerweise thermofixiert, um das Pigment zu fixieren.

Anwendungen

Ideal für natürliche und synthetische Stoffe, Pigmentdruck wird in der Mode eingesetzt, Heimtextilien, und maßgeschneiderte Kleidung.

Vorteile

- Vielseitigkeit: Geeignet für eine Vielzahl von Stoffen.

- Farbechtheit: Bietet eine gute Farbechtheit und Waschbeständigkeit.

- Detail: Kann feine Details und lebendige Farben drucken.

Nachteile

- Textur: Drucke können sich auf der Stoffoberfläche steif anfühlen.

- Fading: Farben können schneller verblassen als bei anderen Methoden, wenn sie nicht richtig fixiert werden.

Wärmetransfer-Vinyl (HTV) Drucken

Beim HTV-Druck werden Designs aus Vinylfolien ausgeschnitten und auf Stoff heißgepresst.

Verfahren

Die Designs werden mit einem Plotter oder Cutter aus Vinylfolien geschnitten. Anschließend wird das geschnittene Vinyl entgittert, um überschüssiges Material zu entfernen, und mit Hitze auf den Stoff gepresst.

Anwendungen

Wird häufig für Sportbekleidung verwendet, individuelle T-Shirts, und Werbeartikel, Der HTV-Druck ist vielseitig und beliebt für Einzelanfertigungen und Kleinauflagen.

Vorteile

- Haltbarkeit: Erzeugt langlebige und waschbare Drucke.

- Vielseitigkeit: Erhältlich in verschiedenen Farben und Ausführungen, einschließlich Metallic und Glitzer.

- Benutzerfreundlichkeit: Einfacher Prozess, der keine umfangreiche Einrichtung erfordert.

Nachteile

- Textur: Vinyldrucke können sich schwer und steif anfühlen.

- Begrenzte Details: Nicht ideal für sehr detaillierte oder mehrfarbige Designs.

Welche Druckmethoden sollten Sie wählen??

Die Wahl der richtigen Stoffdruckmethode hängt von Ihren spezifischen Anforderungen ab. Berücksichtigen Sie die Art des Stoffes, Designkomplexität, Bestellgröße, und Budget.

Siebdruck eignet sich hervorragend für große Mengen mit einfachen Designs, während DTG ist perfekt für detaillierte und farbenfrohe individuelle Drucke. DTF bietet Vielseitigkeit bei allen Stoffen, Sublimation sorgt für lebendige Farben für Polyester, Pigmentdruck funktioniert gut für eine Vielzahl von Materialien, Und HTV ist hervorragend für die Haltbarkeit geeignet, individuelle Drucke.

Abschluss

Sich in der Welt des Stoffdrucks zurechtzufinden, kann überwältigend sein, Aber wenn Sie die Vor- und Nachteile verschiedener Druckmethoden auf Stoff kennen, können Sie die beste Wahl für Ihr Projekt treffen. Egal, ob Sie auf der Suche nach Lebendigkeit sind, langlebige Drucke oder kostengünstige Lösungen für Großaufträge, Es gibt eine Drucktechnik, die Ihren Anforderungen entspricht. Berücksichtigen Sie Ihren Stofftyp, Designdetails, und Produktionsvolumen, um eine fundierte Entscheidung zu treffen, die Ihre kreativen Visionen zum Leben erweckt.

FAQs

1. Was ist die haltbarste Stoffdruckmethode??

Siebdruck und Sublimationsdruck sind für ihre Haltbarkeit bekannt, Hält mehreren Wäschen stand, ohne dass es zu deutlichem Ausbleichen oder Rissen kommt.

2. Kann ich den DTF-Druck auf jedem Stoff verwenden??

Der DTF-Druck ist äußerst vielseitig und kann auf einer Vielzahl von Stoffen eingesetzt werden, einschließlich Baumwolle, Polyester, und Mischungen.

3. Was ist die beste Druckmethode für komplexe?, mehrfarbige Designs?

Der DTG-Druck ist ideal für detaillierte und mehrfarbige Designs, bietet hohe Auflösung und lebendige Farben.

4. Ist der Sublimationsdruck auf bestimmte Stoffe beschränkt??

Ja, Der Sublimationsdruck funktioniert am besten auf Stoffen mit Polyester- und Polymerbeschichtung, da der Bindungsprozess erforderlich ist, damit der Farbstoff in das Material eindringen kann.

5. Wie kann ich die Rüstzeit für den Stoffdruck verkürzen??

Methoden wie DTG- und HTV-Druck haben im Vergleich zum Siebdruck minimale Rüstzeiten, Dies macht sie bei kleinen Aufträgen und schnellen Bearbeitungszeiten effizienter.