収益性の高い印刷ビジネスを運営するには、適切な印刷テクノロジーを選択することが不可欠です. プリントオンデマンドが成長を続ける中, 何千もの企業が、最初から適切な機器を選択することで多大な収益を生み出しています.

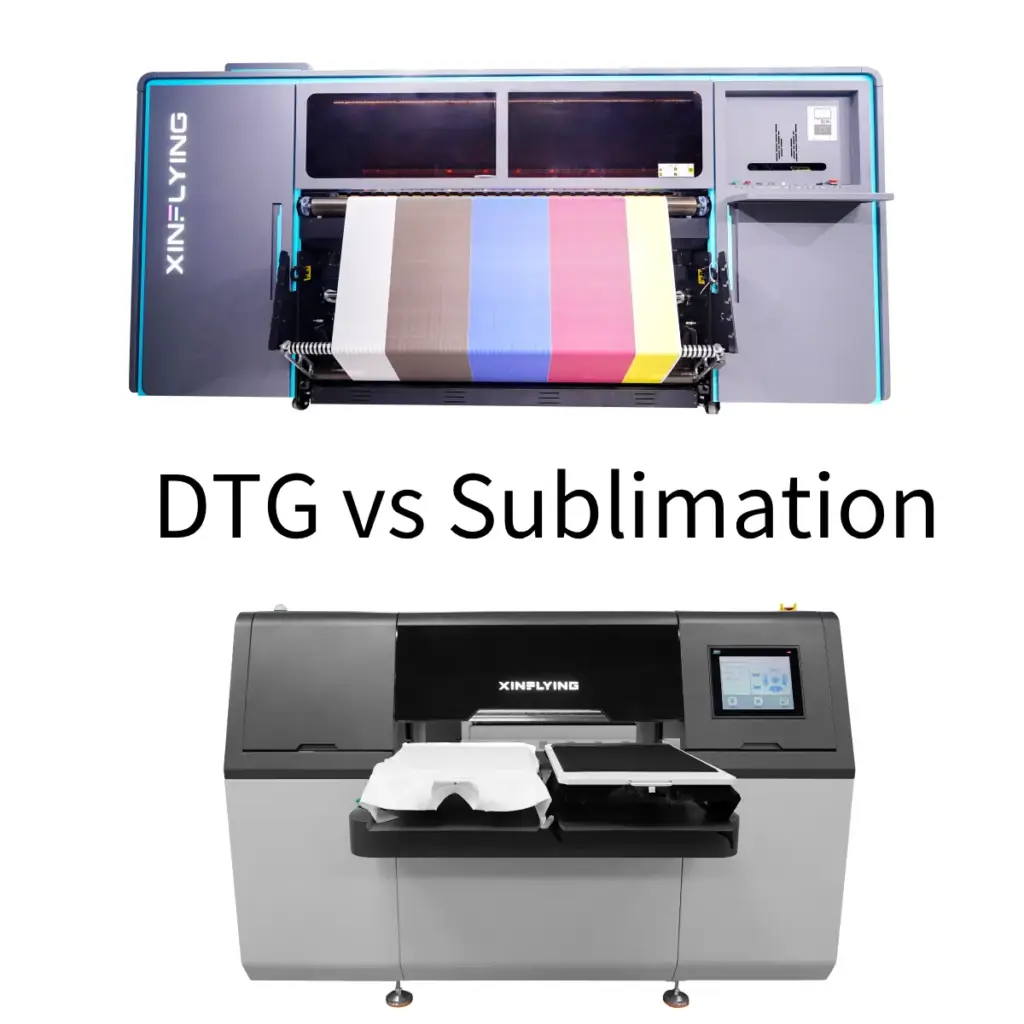

最も議論されているテクノロジーの中には、 昇華印刷 そして DTG (衣服に直接) 印刷. どちらも優れた印刷品質で知られています, しかし、それぞれが異なる材料を提供します, ワークフロー, ビジネスニーズ. それで, 印刷の目的に最適なオプションはどれですか?

このガイドでは、昇華印刷と DTG 印刷の違い、つまり品質について詳しく説明します。, 料金, 互換性, 耐久性, などなど - 情報に基づいて長期的な意思決定を行うことができます.

昇華印刷とは何ですか?

昇華プリントでは、制御された熱と圧力を使用して固体染料を気体に変換します。, ポリエステル繊維またはポリマーでコーティングされた表面に直接接着します。. このプロセスは、昇華インクを使用して特殊な昇華紙にデザインを印刷する昇華プリンターから始まります。.

インクが素材と融合するため、, プリントは生地の一部になるため、ひび割れることはありません, 皮をむく, またはフェード. 昇華型は販促品に最適です, スポーツウェア, およびオンデマンドプリントのテキスタイル.

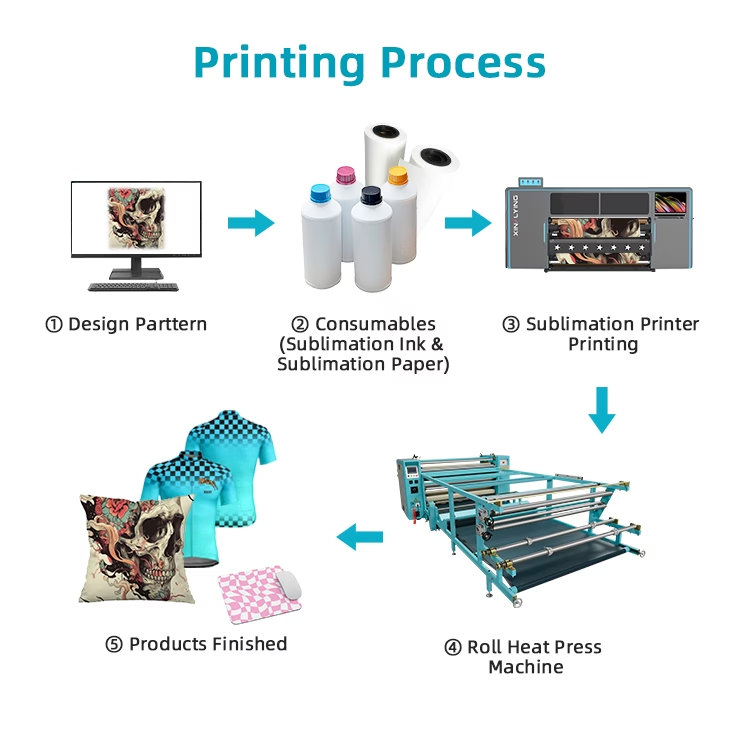

昇華印刷の仕組み

- デザインを作成する グラフィックデザインソフトを使って.

- ミラーリングされたアートワークを印刷する 昇華インクを使用して昇華紙に印刷する.

- 用紙の位置を決めます 製品に貼り付け、耐熱テープで固定します。.

- 熱と圧力を加える ヒートプレスを使用する - これによりインクがガスに変わり、素材に永久的に接着されます。.

- 製品を冷ましてください, 紙を剥がすとパーマネントが現れます, 鮮やかなプリント.

昇華の長所

- 鮮やかに演出します, 長持ちする色

- インクが生地の一部になるため、ひび割れや剥がれが発生しません。

- スムーズ, 凹凸のないシームレスな仕上がり

- 写真やフルカラーのデザインに最適

- 多くの製品に対応: マグカップ, タンブラー, 衣服, 装飾, 等.

昇華の短所

- ポリエステル生地またはポリマーコーティングされたアイテムのみに対応

- 機能しません 100% コットン

- 明るい素材または白い素材に限る

- 機器や消耗品は高価になる可能性があります

- 熱伝達ステップにより生産速度が遅くなる可能性がある

DTG印刷とは?

DTG (衣類に直接) インクジェットプリンターのような印刷機能, 生地に直接プリントしますが、. インクが前処理された衣服に接着し、非常に精細な仕上がりを実現します。, ソフトプリント. DTG は複雑なデザインに最適です, 写真プリント, そして小ロットの注文.

昇華とは異なります, DTG は天然繊維、特に綿に最適です。.

DTG 印刷の仕組み

- 衣類の前処理をする インクを適切に接着させるため.

- アートワークを準備する デザインまたはRIPソフトウェアを使用する.

- 衣服に直接プリントする 白インクとカラーインクを使用する.

- インクを硬化させる ヒートプレスまたは内蔵硬化装置を使用.

- 最終製品 ソフトの準備ができています, 詳細な印刷.

DTG印刷のメリット

- 綿や天然繊維の生地に最適

- 非常に詳細な, 暗い色の衣服にもカラフルなプリント

- 迅速な生産とシンプルなワークフロー

- 少量注文やカスタムオーダーに最適

DTG印刷の短所

- プリントは生地の表面に残るため、時間の経過とともに色褪せる可能性があります

- 生地の前処理が必要です

- ポリエステルへの昇華と比較して耐久性が劣ります。

- 暗い生地や質感の高い生地では色の鮮やかさが薄れる場合があります

DTG vs. 昇華: 主な違い

1. ファブリックの互換性

- 昇華: ポリエステル, ポリブレンド, ポリマーコーティングされた製品

- DTG: 綿および綿混紡生地

2. 印刷品質

- 昇華: 超鮮やか, スムーズ, 素材に永久的に注入されます

- DTG: 非常に詳細ですが、暗い衣服や織り目加工の衣服では鮮やかさが薄れる場合があります

3. セットアップ費用

- DTG: 初期投資は高くなりますが、経常的な消耗品コストは少なくなります

- 昇華: 設備コストは低いが、昇華インクが必要 & 紙の長期

4. ランニングコスト

- DTG: $0.50– 色と複雑さに応じて、プリントあたり $3.50

- 昇華: 大規模なバッチや全面印刷の場合、よりコスト効率が高くなります。

5. 生産速度

- DTG: 既製服の方が早い, ただし前処理が必要

- 昇華: フルファブリックデザインでは印刷は速いがワークフローが長くなる

6. 耐久性

- 昇華: 非常に耐久性があり、生地の一部になります

- DTG: 品質は良いですが、時間の経過とともに色褪せたりひび割れたりする可能性があります

7. 環境への影響

- DTG: 水性インクを使用, 環境に優しい; 前処理はさまざまです

- 昇華: 水性染料ですが、熱プレスには高エネルギーが必要です

| カテゴリ | DTG印刷 | 昇華印刷 |

|---|---|---|

| 材料の互換性 | こんな方に最適 100% コットン & 天然繊維 | ポリエステルまたはポリマーコーティングされたアイテムにのみ機能します |

| 印刷品質 | 高精細度; 複雑なデザインに最適 | 非常に活気のある; ポリエステルに写実的な |

| セットアップコスト | 初期投資が高額になる | セットアップコストの削減 |

| ランニングコスト | 印刷あたりのコストが高い (インク + 前処理) | 印刷あたりのコストを削減, 特にバルクの場合 |

| 生産速度 | 少量の注文でも迅速に対応; 前処理が必要 | 高速印刷; フルファブリックの生産には時間がかかります |

| 耐久性 | 良い, ただし時間の経過とともに色褪せたり剥がれたりする可能性があります | 素晴らしい; 繊維に溶け込んだ, 割れません |

| 環境への影響 | 水性インクだが前処理化学薬品が必要 | 環境に優しいインク; 熱エネルギーの使用に依存します |

| 最適な用途 | 小規模~中規模の注文, コットンアパレル, 詳細なアートワーク | 大量注文, ポリエステルの衣類, スポーツウェア, プロモーションアイテム |

DTG と昇華のどちらを選択するべきか?

次の場合は DTG を選択してください:

- あなたは一緒に働いています 100% コットン

- 必要です 非常に詳細なデザインまたはカラフルなデザイン

- あなたが扱います 少量またはカスタムオーダー

- あなたが好む 最小限のセットアップ そして迅速な生産

次の場合は昇華を選択してください:

- 印刷するのは ポリエステルまたは合成繊維

- 必要です 耐久性のある, 永続, 鮮やかな結果

- あなたがプロデュースします 大量注文

- あなたは 起動する スケーラブルな生産ニーズに対応

結局のところ, 最適な選択はビジネス モデルによって異なります, 製品範囲, そして顧客の需要.

結論

昇華印刷と DTG 印刷はどちらも優れた結果をもたらしますが、目的は異なります。.

- DTG 綿の衣類に最適です, 複雑なデザイン, 小規模から中規模の注文.

- 昇華 ポリエステル素材に最適です, 鮮やかな色, そして大量生産.

どのテクノロジーを選択しても, シンフライング プロフェッショナルを提供します, 信頼性のある, ビジネスの成長をサポートするコスト効率の高い印刷ソリューション.

今すぐXinflyingにお問い合わせください 優れたパフォーマンスを発揮するプリンターを探索する, 優れた耐久性, オンデマンド印刷ビジネスに比類のない価値をもたらします.