導入

A heat press machine is one of the most essential pieces of equipment for any custom T-shirt business. Whether you’re working with DTF transfers, 昇華, heat transfer vinyl (HTV), or specialty applications, the quality of your heat press directly affects print durability, consistency, and production efficiency.

しかし, with so many heat press machines available on the market—each offering different structures, sizes, pressure systems, and control technologies—choosing the right one can feel overwhelming.

As the global custom apparel industry continues to grow, now is an ideal time to start or scale your printing business. Selecting the right heat press machine is a critical first step toward long-term success. With a clear understanding of machine types, technical factors, and production requirements, you can confidently invest in equipment that supports your business goals.

This guide by シンフライング will walk you through everything you need to know to choose the right heat press machine for your custom T-shirt business.

Key Factors to Consider When Choosing a Heat Press

機械を選ぶ前に, it’s important to evaluate several key factors that directly impact print quality, workflow efficiency, and return on investment.

1. Platen Size and Workspace

Platen size determines the maximum design area you can press. When choosing a heat press, consider both your common order sizes and your available workspace.

| Platen Category | Common Sizes | Ideal Applications |

|---|---|---|

| Extra Small | 4”×6” – 6”×8” | Labels, 袖, baby garments |

| Small | 9”×12” – 14”×16” | Hobby projects, patches |

| 中くらい | 15”×15”, 16”×16” | Standard T-shirts, daily orders |

| Large | 16”×20” | Full-front/back prints |

| Extra Large | 18”×20” and above | Oversized or specialty jobs |

For most professional T-shirt businesses, 15”×15”, 16”×16”, or 16”×20” heat presses provide the best balance between versatility and efficiency.

2. Temperature Control Accuracy

Precise temperature control is essential for consistent results. Different materials require different heat settings—cotton typically needs higher temperatures, while polyester and blends require lower heat to avoid scorching.

Xinflying heat press machines are equipped with digital temperature control systems, ensuring accurate heat output and stable performance throughout long production runs.

3. Machine Type

Heat press machines come in several structural designs, each suited for different workflows:

- Clamshell Heat Press

コンパクト, 操作が簡単, and space-saving. Ideal for beginners and light production. - Swing-Away Heat Press

The upper platen swings away completely, providing safer operation and more even pressure—great for thicker garments. - Drawer (Pull-Out) ヒートプレス

A sliding lower platen allows easier garment positioning and improved safety, combining the benefits of clamshell and swing-away designs. - Pneumatic Heat Press

Uses air pressure for automatic pressing, ideal for high-volume industrial production.

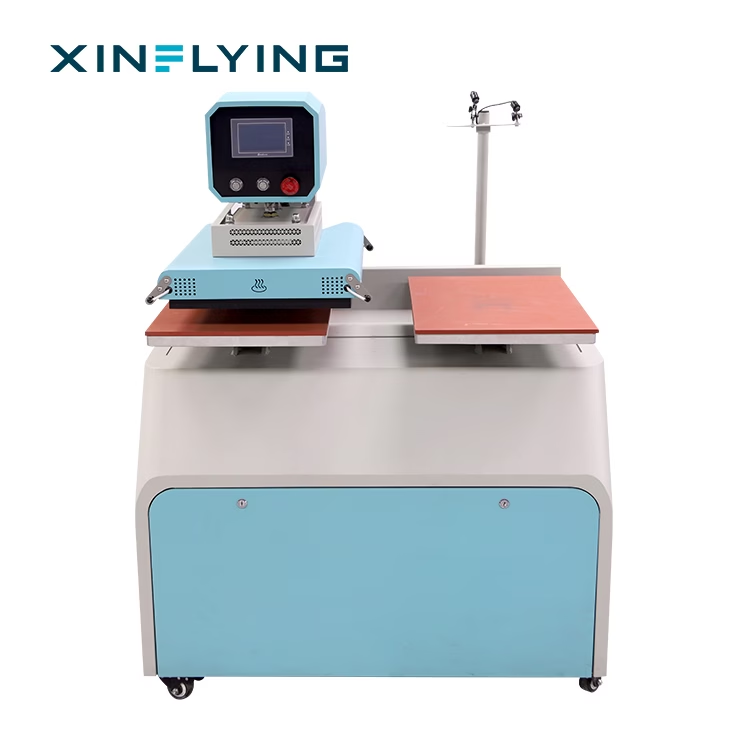

Xinflying offers multiple heat press configurations to match different business scales and production demands.

4. Pressure Adjustment

Uniform pressure is just as important as temperature. Different fabrics, transfer papers, and garment thicknesses require adjustable pressure for proper adhesion.

Modern Xinflying heat press machines feature adjustable or assisted pressure systems, ensuring even pressure distribution across the platen for clean, 耐久性のある転送.

5. Heat Distribution Consistency

Even heat distribution across the platen ensures consistent color transfer and long-lasting prints. Poor heat distribution can lead to peeling, 色褪せ, or uneven finishes.

Xinflying heat presses use high-quality heating elements and precision-built platens, delivering stable and uniform heat across the entire pressing area.

How to Choose the Right Heat Press for Your Business

ステップ 1: Assess Your Production Needs

Evaluate your daily order volume, typical garment sizes, and printing techniques. This helps determine the platen size, machine type, and automation level you need.

ステップ 2: Select the Appropriate Machine Type

Match the machine structure to your workflow. Startups often prefer clamshell presses, while growing businesses benefit from swing-away or drawer-style models for safety and flexibility.

ステップ 3: Define a Practical Budget

Set a realistic budget based on your production scale. While advanced features improve efficiency, the best investment is equipment that meets your current needs while allowing room for growth.

ステップ 4: Research Brand Reliability and Support

Beyond specifications, reliable after-sales service is critical. Xinflying provides テクニカルサポート, operational guidance, and long-term parts availability, ensuring your business runs smoothly after installation.

ステップ 5: Test and Optimize After Purchase

Before full production, test different temperature, プレッシャー, and timing settings. Keep records of optimal parameters for different materials to maintain consistent quality.

結論

Choosing the right heat press machine is about aligning equipment capabilities with your business goals. By considering platen size, machine type, pressure control, and long-term support, you can make a confident and informed decision.

Xinflying heat press machines are designed for reliability, ease of operation, and consistent performance—whether you’re launching a new custom apparel brand or expanding an existing production line. With a full range of models for different production scales and dependable technical support, Xinflying helps you build a strong foundation for long-term success in the custom T-shirt printing industry.