수익성 있는 인쇄 사업을 운영하려면 올바른 인쇄 기술을 선택하는 것이 필수적입니다.. 주문형 인쇄가 지속적으로 증가함에 따라, 수천 개의 기업이 처음부터 올바른 장비를 선택하여 상당한 수익을 창출하고 있습니다..

가장 논란이 많은 기술 중에는 승화 인쇄 그리고 DTG (의류에 직접 판매) 인쇄. 둘 다 뛰어난 인쇄 품질로 유명합니다., 하지만 각각 다른 재료를 사용합니다., 워크플로, 그리고 비즈니스 요구 사항. 그래서, 귀하의 인쇄 목표에 가장 적합한 옵션은 무엇입니까??

이 가이드에서는 승화와 DTG 인쇄의 품질 차이를 자세히 설명합니다., 비용, 호환성, 내구성, 그리고 더 많은 정보를 바탕으로 장기적인 결정을 내릴 수 있습니다..

승화 인쇄란??

승화 인쇄는 제어된 열과 압력을 사용하여 고체 염료를 가스로 변환합니다., 폴리에스터 섬유 또는 폴리머 코팅 표면에 직접 접착. 이 프로세스는 승화 잉크를 사용하여 특수 승화 용지에 디자인을 인쇄하는 승화 프린터로 시작됩니다..

잉크가 재료와 융합되기 때문에, 프린트가 직물의 일부가 되므로 갈라지지 않습니다., 벗기다, 또는 페이드. 승화는 판촉물에 이상적입니다., 운동복, 주문형 인쇄 직물.

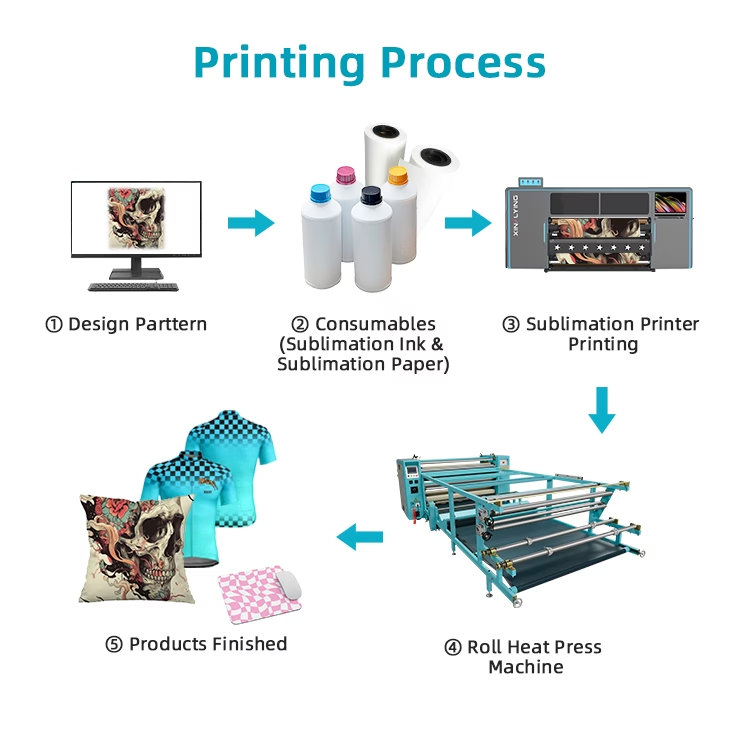

승화 인쇄 작동 방식

- 디자인 만들기 그래픽 디자인 소프트웨어를 사용하여.

- 미러링된 아트워크 인쇄 승화 잉크를 사용하여 승화 종이에.

- 종이를 위치시키세요 제품에 부착한 후 내열 테이프로 고정하세요..

- 열과 압력을 가해 열 프레스를 사용하면 잉크가 가스로 바뀌고 재료에 영구적으로 접착됩니다..

- 제품을 식혀주세요, 그런 다음 종이를 벗겨내면 영구 접착제가 나타납니다., 생생한 인쇄.

승화의 장점

- 생생하게 연출, 오래 지속되는 색상

- 잉크가 직물의 일부가 되어 갈라지거나 벗겨짐이 없습니다.

- 매끄러운, 돌출된 질감이 없는 매끄러운 마감

- 사진 및 풀 컬러 디자인에 탁월

- 많은 제품에서 작동: 머그잔, 텀블러, 의복, 장식, 등.

승화의 단점

- 폴리에스테르 직물 또는 폴리머 코팅 품목에만 호환됩니다.

- 작동하지 않음 100% 면

- 가볍거나 흰색 재료로 제한됨

- 장비 및 소모품 비용이 많이 들 수 있음

- 열 전달 단계로 인해 생산 속도가 느려질 수 있습니다.

DTG 인쇄는 무엇입니까??

DTG (의류에 직접 전달) 잉크젯 프린터와 같은 인쇄 기능, 그러나 직물에 직접 인쇄됩니다.. 잉크가 사전 처리된 의류와 접착되어 매우 섬세한 디테일을 만들어냅니다., 부드러운 인쇄물. DTG는 복잡한 설계에 이상적입니다., 사진 인쇄, 그리고 소량 주문.

승화와 달리, DTG는 천연 섬유, 특히 면에 가장 잘 작용합니다..

DTG 인쇄 작동 방식

- 의류 전처리 적절한 잉크 접착을 보장하기 위해.

- 작품을 준비하세요 디자인 또는 RIP 소프트웨어 사용.

- 의류에 직접 인쇄 흰색과 유색 잉크를 사용하여.

- 잉크를 치료 열 프레스 또는 내장 경화 장치 사용.

- 최종 제품 부드러운 준비가되어 있습니다, 상세한 인쇄.

DTG 프린팅의 장점

- 면 및 천연섬유 직물에 탁월

- 매우 상세한, 컬러풀한 프린트 – 어두운 옷에도 가능

- 빠른 생산과 간단한 작업 흐름

- 소량 또는 맞춤 주문에 적합

DTG 인쇄의 단점

- 인쇄물이 직물 표면에 남아 시간이 지남에 따라 희미해질 수 있습니다.

- 직물 전처리 필요

- 폴리에스터 승화에 비해 내구성이 떨어짐

- 어둡거나 질감이 심한 직물에서는 색상이 덜 선명할 수 있습니다.

DTG 대. 승화: 주요 차이점

1. 패브릭 호환성

- 승화: 폴리에스테르, 폴리 블렌드, 폴리머 코팅 제품

- DTG: 면과 면 혼방 소재

2. 인쇄 품질

- 승화: 매우 활기 넘치는, 매끄러운, 재료에 영구적으로 주입됩니다.

- DTG: 매우 세밀하지만 어둡거나 질감이 있는 의류에서는 생동감이 덜 나타날 수 있습니다.

3. 설치 비용

- DTG: 초기 투자 비용은 높지만 반복되는 소모품 비용은 적습니다.

- 승화: 장비 비용은 저렴하지만 승화 잉크가 필요함 & 종이 장기

4. 운영 비용

- DTG: $0.50– 색상 및 복잡성에 따라 인쇄당 $3.50

- 승화: 대규모 배치 및 전체 인쇄에 더욱 비용 효율적입니다.

5. 생산 속도

- DTG: 기성복의 경우 더 빠르게, 하지만 전처리가 필요합니다

- 승화: 프린팅은 빠르지만 전체 패브릭 디자인을 위한 작업 흐름은 길어집니다.

6. 내구성

- 승화: 내구성이 매우 뛰어남 - 패브릭의 일부가 됨

- DTG: 품질은 좋으나 시간이 지나면 변색되거나 갈라질 수 있습니다.

7. 환경에 미치는 영향

- DTG: 수성 잉크를 사용합니다., 환경 친화적인; 전처리가 다양하다

- 승화: 수성 염료이지만 열 프레싱에 높은 에너지가 필요함

| 범주 | DTG 인쇄 | 승화 인쇄 |

|---|---|---|

| 재료 호환성 | 다음에 가장 적합 100% 면 & 천연섬유 | 폴리에스테르 또는 폴리머 코팅 품목에만 적용 가능 |

| 인쇄 품질 | 높은 디테일; 복잡한 디자인에 적합 | 매우 생동감 넘치는; 폴리에스터에 사실적 |

| 설치 비용 | 높은 초기 투자 | 낮은 설치 비용 |

| 운영 비용 | 더 높은 인쇄당 비용 (잉크 + 전처리) | 인쇄당 비용 절감, 특히 대량으로 |

| 생산 속도 | 소액주문에 빠른; 전처리 필요 | 빠른 인쇄; 전체 직물 생산의 경우 속도가 느림 |

| 내구성 | 좋은, 하지만 시간이 지남에 따라 퇴색/벗겨질 수 있습니다. | 훌륭한; 섬유로 융합, 깨지지 않을 것이다 |

| 환경에 미치는 영향 | 수성 잉크이지만 전처리 화학 물질이 포함됨 | 친환경 잉크; 열에너지 사용에 따라 다름 |

| 최고의 대상 | 중소 규모 주문, 면 의류, 상세한 삽화 | 대량 주문, 폴리에스터 의류, 운동복, 프로모션 아이템 |

DTG 또는 승화를 선택해야 합니까??

다음과 같은 경우 DTG를 선택하세요.:

- 당신은 함께 일합니다 100% 면

- 당신은 필요 매우 세밀하거나 화려한 디자인

- 당신이 처리 소규모 또는 맞춤 주문

- 당신은 선호 최소한의 설정 그리고 빠른 생산

다음과 같은 경우 승화를 선택하세요.:

- 당신은 인쇄 폴리에스테르 또는 합성 직물

- 당신은 필요 튼튼한, 영구적인, 생생한 결과

- 당신은 생산 대량 주문

- 당신은 시작 확장 가능한 생산 요구 사항

궁극적으로, 최선의 선택은 비즈니스 모델에 따라 다릅니다., 제품군, 그리고 고객의 요구.

결론

승화 인쇄와 DTG 인쇄 모두 뛰어난 결과를 제공하지만 용도는 다릅니다..

- DTG 면 의류에 가장 적합합니다., 복잡한 디자인, 그리고 중소 규모 주문.

- 승화 폴리에스테르 소재에 이상적입니다., 생생한 색상, 그리고 대량 생산.

어떤 기술을 선택하든 상관 없습니다., 신플라잉 전문적인 제공, 믿을 수 있는, 비즈니스 성장을 지원하는 비용 효율적인 인쇄 솔루션.

지금 Xinflying에 문의하세요 탁월한 성능을 제공하는 프린터를 탐색합니다., 뛰어난 내구성, 주문형 인쇄 비즈니스를 위한 탁월한 가치.