XINFLYING DTF MACHINE-Stable Structure, Reliable Printing

√ Print on Any Kind of Fabric

√ Make Unlimited Customize Designs in No Time

√ Same Quality as Screen Print

DTF Solutions for All Stages

Beginner

XF-450pro 2 Head All-in One A2 DTF-skrivare

- Produktivitet: 8Passera: 6m²/h

- Utskriftsbredd: 16''

- Skrivhuvud: 2St. Epson i1600-A1/F1080-A1/XP600/i3200-A1

Growing

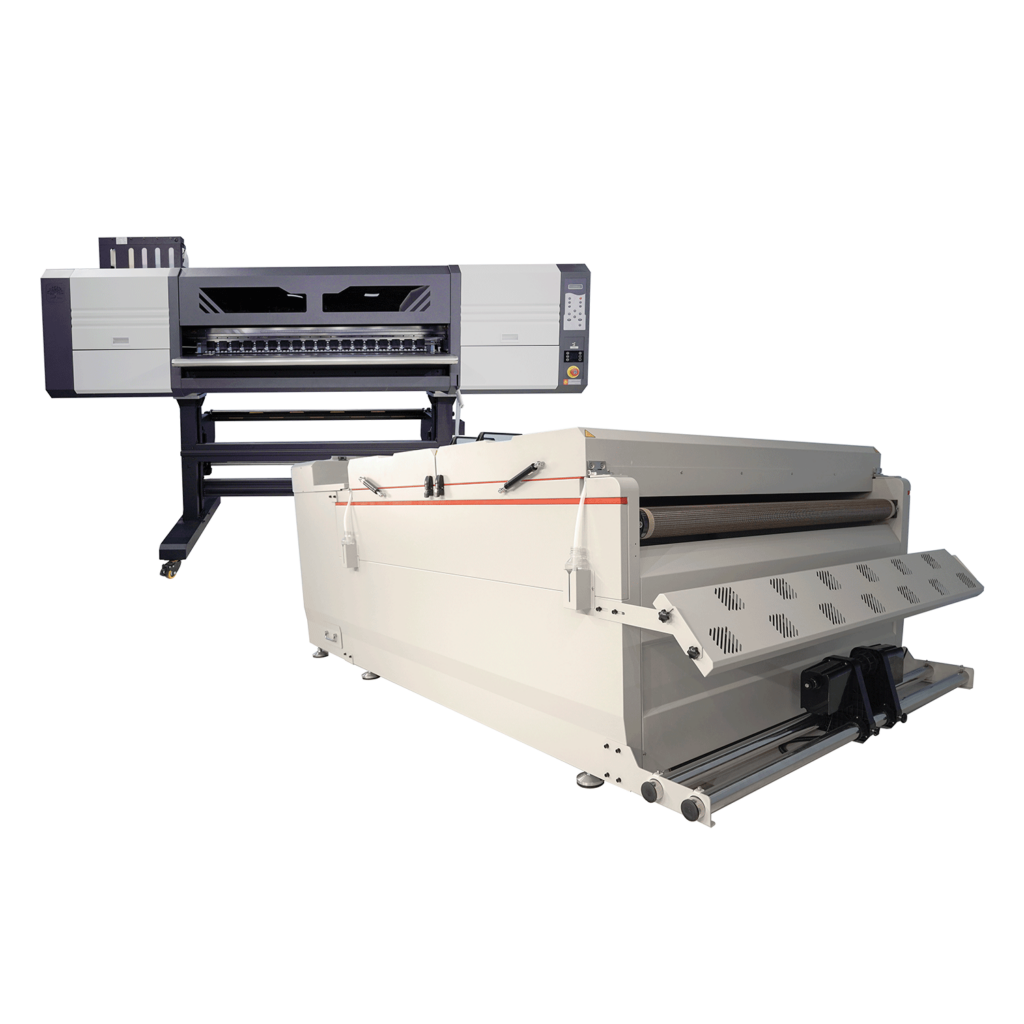

C605+H6502 5 Head 24'' I3200 DTF-skrivare

- Produktivitet: 6Passera: 36m²/h

- Utskriftsbredd: 24”

- Skrivhuvud: 5PCS I3200-A1

High Volume

L1208+H1300 48 Inch I3200-A1 DTF-skrivare

- Produktivitet: 4Passera:74m²/h

- Utskriftsbredd: 48″

- Skrivhuvud: 8PCS Epson 13200-A1

8 Färger

C604+H6501 24 tums DTF-skrivare

- Produktivitet: 4Passera: 24m²/h

- Utskriftsbredd: 24”

- Skrivhuvud: 4PCS 13200-A1

Why DTF Printer is So Popular for T Shirt Printing?

1. No pre-treatment is required;

2. Premium silkscreen quality;

3. Cost-effecitve;

4. Suitable for all fabric;

Only 5 simple steps are required to use a DTF printer to print on a T-shirt:

1. Print the design;

2. Spread powder;

3. Melt and dry;

4. Cut to piece;

5. Värmepress;

What Can You Make with DTF Printing?

DTF printing is a new multifunctional printing technology, suitable for almost all types of fabrics. Works on both white and dark textiles. No pre-treatment is required.

- T-Shirts & Sweatshirts

- Hoodies & Pullovers

- Pants & Leggings

- Canvas & Denim

- Hattar

- Bags

- Skor

- and more......

Why XINFLYING DTF?

All services in one place

- Onboarding Service

We offer a dedicated team of professionals to share video/screen share to ensure you get set up and print right away.

- On/offline Training Support

We provide important after-sales support and training, free online training, and on-site coaching to customers worldwide. There are several video programs available as training resources.

- "Heads and All" Garanti

We provide a 3-6 month free warranty for print heads, and all printers are backed by a standard 24 months. You can also extend the warranty for peace of mind.

- Köpa 1 Get More

Buying Sublistar Ultra DTF machine, you will get a DTF Supplies bundled package valued at $300 for free, including 100m DTF film, 2kg DTF powder, 1set DTF inks. 1set cleaning kit.

- One-stop printing solutions

We offer a wide range of environmentally friendly inks and coatings, and offer print media designed for a variety of printing needs. With our supplies, you will get a finished product with good hand, excellent color gamut and strong wash fastness.

Frequently Asked Questions

What is DTF transfer printing?

Dtf(direct to film) process is as simple as its name implies-printing on the film and directly transferred to the fabric. The most prominent factor that makes this process worthwhile for more people is the freedom to choose almost any fabric. Whether it is polyester, bomull, silk or synthetic fibers such as man-made fibers or terry cloth, the DTF printing process will definitely do magic to them.

DTF -skrivare vs. DTG, vilket är bättre?

DTF printing is more durable.

DTF printers transfer designs onto garments via a special film, while DTG printers print directly onto the fabric.

DTG printers are best for natural fibers, while DTF printers can print on a wider range of materials.

DTF printers generally produce more vibrant colors on dark fabrics, but DTG printers are faster for individual garments.

What are the differences between UV DTF printers and DTF printers?

Similarities between UV DTF printers and DTF printers: Both DTF and UV DTF printers call for the design to initially be printed on a PET film before being transferred to the item.

Differences: UV DTF printers use a different type of ink than DTF printers do. Unlike DTF printers, UV DTF printers employ UV ink.

What are the differences between UV DTF printers and UV printers?

UV printers and UV DTF printers both use UV heating technology and UV ink, which is a similarity. As a result, both printers can generate prints that are of a high enough caliber.

UV printers work directly on an object’s surface, which is where they differ. The UV printer might not deliver adequate results when printing on an object with a sloped surface.

Benefits of Xinflying DTF

- The highest quality print of any direct-to-film printer on the market.

- Heavy professional production machine. Can be used 24/7.

- The lowest maintenance cost of any direct-to-film printer.

- Prints on any kind of fabric. Bomull, Polyester, TriBlends, 50/50 Fabrics.

- Get free DTF supplies, Rip software and online technical support.

- Free training by XINFLYING Expert Technician! No Extra Charges.

We Are Here to Assist You

Feel free to contact us or just drop a line here. Our support stuff will reach you very soon.