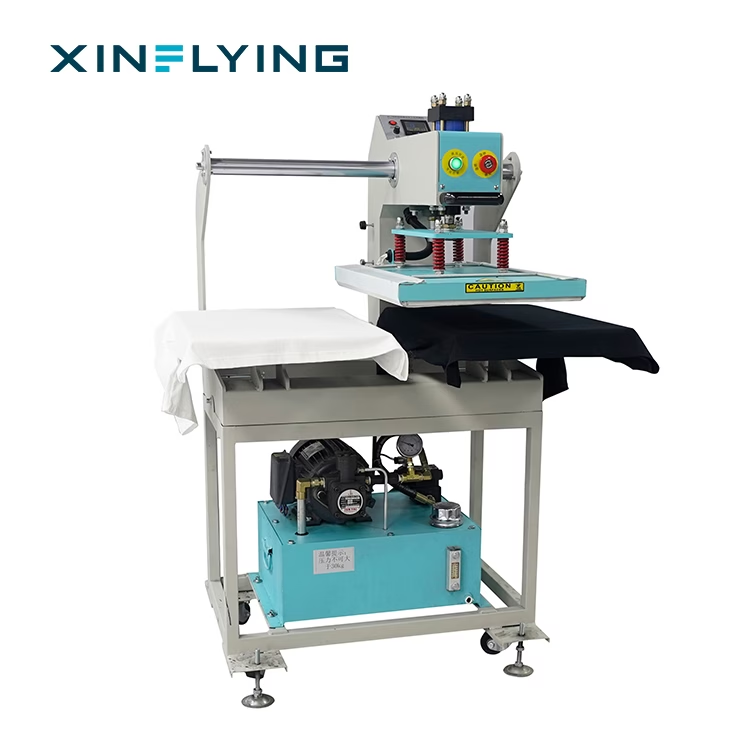

6040(7SEI) Halbautomatische hydraulische Doppelstations-Wärmeübertragungsmaschine

Produkthighlights:

1.Double Station Hydraulic Design

Allows loading and pressing simultaneously to improve production efficiency.

2.Uniform Pressure & Heat Control

Hydraulic system ensures consistent pressure and stable transfer results.

3.Reliable for Continuous Operation

Built for long working hours in garment and textile production.

4.Versatile Heat Transfer Applications

Suitable for garments, Stoffe, and various heat transfer materials.

Professionelle Funktionen

Produktspezifikationen

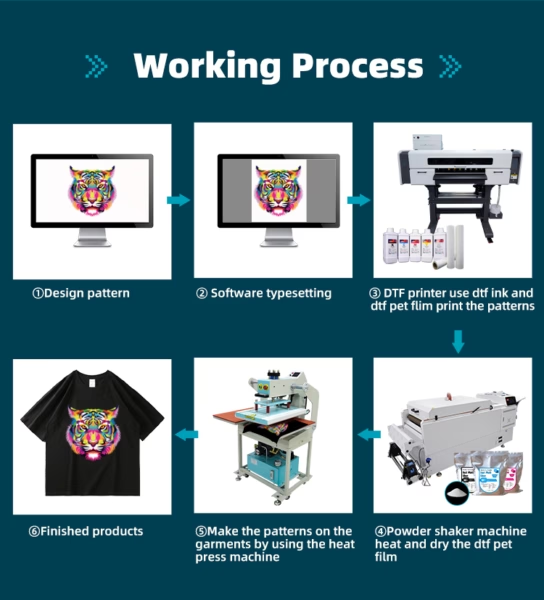

Druckprozess

Anwendung

FAQ

Industrial-grade working platform equipped with a protective upper cover. The design enhances operator safety while maintaining easy access to the pressing area, suitable for continuous professional use.

Robust main frame structure combined with an integrated control box. Provides solid mechanical support while housing key electrical components, ensuring safe operation, Haltbarkeit, and easy maintenance access.

Precision pressure adjustment system integrated with control components and support frame. Allows accurate regulation of pressing force and operational stability, improving consistency and reducing operator fatigue.

Complete heat press unit featuring a reinforced upper heating plate and stable lower working table. Designed for even pressure distribution and consistent heat transfer, ensuring reliable results in long-duration production.

| Modell | 6040(7SEI) |

|---|---|

| Druckgröße | 60x40 |

| Stromspannung (V) | 220V 1 Phase/220V 3 Phase/380V 3 Phase |

| Zeitlimit | 0-999S |

| Leistung(KW) | 4.3KW |

| Temperaturbereich( °C) | 0-399 °C |

| Maschinengröße | 100*82*140CM |

| Paketgröße | 195* 85*140CM |

| Nettogewicht | 209.5KG |

| Bruttogewicht | 280KG |

Erstellen Sie das Kunstwerk mit professioneller Designsoftware.

Passen Sie Layout und Farben in der RIP-Software an.

Print the design on to transfer.

Übertragen Sie das Bild mit einer Heißpresse auf Polyestergewebe (190–210°C, 30-60er Jahre).

Hell, dauerhaft, und langanhaltende Ergebnisse.

Q1: How do I use a heat press machine?

A: To use a heat press machine, simply set the temperature, Druck, and time based on the material you’re printing on. Place the item (Z.B., t-shirt) on the heat press, position your design, close the press, and apply heat and pressure. Wait for the timer to finish, then remove your item.

Q2: Can I use a heat press machine for all fabrics?

A: Ja, heat press machines can be used on most fabrics, einschließlich Baumwolle, Polyester, und Mischungen. Jedoch, different fabrics may require different temperature and time settings, so always check the fabric’s heat tolerance.

Q3: What is the difference between hydraulic and manual heat press machines?

A: Hydraulic heat press machines use hydraulic pressure for even distribution, offering more consistent results and greater efficiency, especially in high-volume production. Manual machines require physical force to apply pressure, which may not be as consistent or efficient for larger batches.

Q4: Can I use a heat press machine for hats?

A: Ja, specialized hat heat press machines are available for printing on hats, Kappen, and other headwear. These machines are designed to handle the unique shape and curvature of hats.

Druckbreite

Produktivität

Druckkopf

Abmessungen

Druckbreite

Produktivität

Druckkopf

Abmessungen

Druckbreite

Produktivität

Druckkopf

Abmessungen

Erfahren Sie mehr über unser DTF, DTG, Sublimationsdrucker, und Verbrauchsmaterialien.

Erfahren Sie mehr über unser DTF, DTG, Sublimationsdrucker und Verbrauchsmaterialien.