Lähde: https://www.silhouetteschoolblog.com

Digitaalinen tulostus on mullistanut vaate- ja tekstiiliteollisuuden, Tarjoaa yrityksille mahdollisuuden tuottaa korkealaatuisia ja räätälöityjä tuotteita helposti.

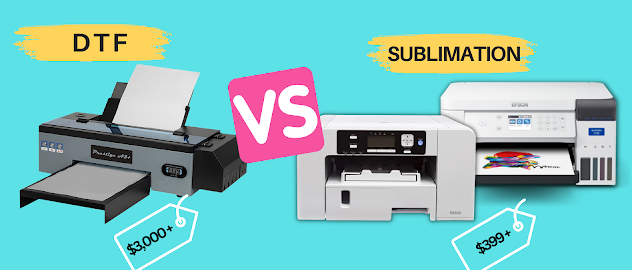

DTF. Vaikka molemmat tekniikat tarjoavat useita etuja, näiden kahden välillä on merkittäviä eroja.

Tässä artikkelissa, VertaammeDTF -tulostusing jasublimointitulostusing ja tutkia heidän etujaan, rajoitukset, ja soveltuvuus erilaisiin painotarpeisiin.

Olemme hajottamassa kaiken erittäin sulavalla tavalla, Joten voit vihdoin valita varmasti digitaalisen tulostusmenetelmän, joka sopii parhaiten yrityksesi tarpeisiin. Olitpa pienimuotoinen yritys vai laajamittainen valmistaja, Tämä artikkeli auttaa sinua tekemään oikean valinnan tulostustarpeisiisi.

[Taulukko] Mitkä ovat erot DTF -tulostuksen ja sublimointitulostuksen välillä?

| Vertailu | DTF-tulostus | Sublimaatiotulostus |

| Työnkulku | 1. Suunnittelu tietokoneella 2. Tulosta lemmikkieläinelokuvalle 3. Paranna mustetta liimajauheella 4. Lämpöpuristin siirtääksesi mallin | 1. Suunnittelu tietokoneella 2. Tulosta sublimointipaperille 3. Lämpöpuristin siirtääksesi mallin |

| Materiaali | Laajempi kangasvalikoima, mukaan lukien puuvilla, polyesteri, ja sekoituksia | Polyesteri- tai polyesteripäällystetyt materiaalit, mukaan lukien vaatteet, bannerit, ja myynninedistämiskohteet. |

| Tulostuslaatu | Korkealaatuiset ja yksityiskohtaiset tulosteet, Elävämpiä ja yksityiskohtaisempia tulosteita | Korkealaatuiset ja yksityiskohtaiset tulosteet |

| Tuotantotehokkuus | Nopeampi käännösajat ja tehokkaampi tuotanto | Puku pieniin määriin |

| Kustannus | Kallis | Kuluttava, mutta edullinen pienille määrille mukautettuja tuotteita |

DTF VS Sublimation -vertailutaulukko

Mikä on DTF-tulostus?

Lähde: https://www.brildor.com

DTF (Suoraan elokuviin) Tulostaminen on digitaalinen tulostustekniikka Se mahdollistaa korkealaatuisten ja yksityiskohtaisten mallien tulostamisen suoraan siirtoelokuvalle, jota voidaan sitten käyttää suunnittelun siirtämiseen kankaaseen.

DTF -tulostus on samanlainen kuin DTG (Suoraan vaatteisiin) painatus, mutta sen sijaan, että tulostaisit suoraan kankaaseen, Suunnittelu on painettu siirtoelokuvalle, joka sitten levitetään kankaaseen lämmönpuristimella.

Kuinka DTF -tulostus toimii?

DTF -tulostustekniikka käyttää erikoistunutta tulostinta, joka on suunniteltu tulostamaan Transfer Film -sovellukseen erikoistuneella DTF mustes. Tulostin soveltaa mustetta siirtoelokuvalle, joka sitten päällystetään kerroksella DTF-jauhe.

The DTF elokuva Sitten asetetaan kankaaseen ja levitetään lämmönpuristimella. Lämpö sulaa DTF -jauheen, joka sulaa musteen kangaskuituihin, Tuloksena korkealaatuinen ja kestävä tuloste.

DTF -tulostuksen edut

DTF -tulostus tarjoaa useita etuja perinteisiin verrattunasublimaatiotulostus menetelmät, mukaan lukien:

- DTF -tulostus tarjoaa mahdollisuuden tulostaa monenlaisia kankaita, mukaan lukien puuvilla, polyesteri, ja sekoituksia.

- Se tuottaa elinvoimaisia ja yksityiskohtaisia tulosteita, jotka ovat pitkäaikaisia ja kestäviä häipymiselle ja pesemiselle.

- DTF -tulostus tarjoaa nopeammat käännösajat ja tehokkaamman tuotannon verrattuna perinteisiin sublimaatiotulostusmenetelmiin.

- DTF -tulostus tarjoaa mahdollisuuden tulostaa laajemmalle tuotevalikoimalle, mukaan lukien kengät, hatut, ja laukkuja.

DTF -tulostuksen rajoitukset

Kun taas monipuolinen, DTF: llä on joitain rajoituksia seuraavana:

- Rajoitettu substraatin yhteensopivuus – DTF -tulostus toimii parhaiten tietyissä kankaissa, kuten puuvilla, polyesteri, ja puuvilla/poly -seokset. Se ei välttämättä kiinnitä hyvin tai tuottaa haluttuja tuloksia joillekin muille materiaaleille, kuten nylonille tai nahkalle.

- Mahdollisuus halkeiluun tai häipymiseen;

- Valkoiset alakankaat vaaditaan kevyisiin kankaita;

- Ei ihanteellinen suurille tilauksille;

- Rajoitettu venyvyys.

Mikä on sublimaatiotulostus?

Lähde: https://www.allprintheads.com

Sublimaatiotulostus on digitaalinen tulostusmenetelmä joka käyttää lämpöä ja painetta väriaineen siirtämiseen materiaaliin, tyypillisesti polyesteri- tai polyesteripäällystetyt tuotteet.

Prosessiin sisältyy suunnittelun tulostaminen sublimointipaperille erikoistuneenasublimaatiomustes, jotka sitten siirretään materiaaliin lämmönpuristimella.

Kuinka sublimaatiotulostus toimii?

Sublimaatiotulostus toimii lämmön avulla muuntamaan muste kaasuksi, joka sitten sitoutuu materiaalin kuituihin. Tämä prosessi johtaa kestävään ja pitkäaikaiseen painotuotteeseen, joka on kestävä häipymiselle, kuorinta, ja halkeilua.

Sublimaatiotulostusta käytetään yleisesti useiden tuotteiden tulostamiseen, mukaan lukien vaatteet, bannerit, opasteet, ja myynninedistämiskohteet. Se on suosittu valinta yrityksille, jotka vaativat pienten määrien täydellistä tulostamista ja mukauttamista.

Sublimaatiotulostuksen edut

- Sublimaatiotulostus tuottaa eläviä ja yksityiskohtaisia tulosteita, jotka ovat pitkäaikaisia ja kestäviä häipymiselle ja pesemiselle;

- Se on monipuolinen tulostusmenetelmä, joka voi tulostaa laajalle tuotteelle, mukaan lukien vaatteet, bannerit, ja myynninedistämiskohteet;

- Sublimaatiotulostus on edullinen tulostusmenetelmä pienille määrille mukautettuja tuotteita.

- Se tarjoaa kyvyn tuottaa värillisiä tulosteita hienoilla yksityiskohdilla ja kaltevuuksilla.

Sublimaatiotulostuksen rajoitukset

- Rajoitettu polyesteri- tai polymeeripinnoitettuihin substraatteihin – Sublimaatiotulostus toimii vain materiaaleissa, joissa on polyesteripinnoite tai korkea polyesteripitoisuus, kuten suorituskykykankaat. Sitä ei voida käyttää luonnollisissa kuiduissa, kuten puuvilla tai liinavaatteet.

- Väriaineen muuttoliike tai aavemainen.

- Ei sovellu monimutkaisille tuotteille – Tuotteet, joissa on monia saumoja, Ridit tai epätasaiset pinnat voivat tuottaa epäjohdonmukaisia sublimointituloksia.

- Tuotantoaika on suhteellisen aikaa vievää muihin tulostusmenetelmiin.

Mikä on parempi yrityksellesi, DTF tai sublimaatiotulostus?

Lähde: https://www.shutterstock.com

Kun kyse on digitaalisen tulostusmenetelmän valitsemisesta yrityksesi tarpeisiin, on otettava huomioon useita tekijöitä.

Harkittavia tekijöitä

Päätettäessä, mikä tulostusmenetelmä on paras yrityksesi tarpeisiin, harkitse seuraavia tekijöitä:

- Kangas/materiaali

Jos joudut tulostamaan monenlaisia kankaita, mukaan lukien puuvilla, polyesteri, ja sekoituksia, DTF -tulostus voi olla parempi vaihtoehto. kuitenkin, Jos sinun on tulostettava vain polyesteri- tai polyesteripäällystetyille materiaaleille, Sublimaatiotulostus voi olla sopivampi.

- Tulostuslaatu

Sekä DTF-tulostus- että sublimaatiotulostus tarjoavat korkealaatuisia ja yksityiskohtaisia tulosteita. kuitenkin, DTF -tulostus voi tarjota elävämpiä ja yksityiskohtaisempia tulosteita verrattuna sublimaatiotulostukseen.

- Tuotantotehokkuus

DTF -tulostus tarjoaa nopeammat käännösajat ja tehokkaamman tuotannon verrattuna sublimaatiotulostukseen.

- Kustannus

Sekä DTF, joka voi olla kallista. Harkitse budjettiasi ja tulostuskustannuksia päätettäessä, mikä menetelmä on paras yrityksesi tarpeisiin.

Faqit DTF -tulostuksessa vs.. Sublimaatiotulostus

1. Mitä tarvitset DTF -tulostamiseen?

DTF (Suoraan elokuviin) Siirtoon sisältyy suunnittelun tulostaminen DTF -elokuvalle, joka sitten siirretään substraattiin liimalla. Tarvitset näitä DTF -tulostamiseen:

- DTF tulostin

- Lämmönpuristuskone

- DTF muste

- DTF Pet -elokuva

- DTF -liimajauhe

2. Mitä tarvitset sublimointitulostukseen?

Sublimaationsiirto sisältää suunnittelun tulostamisen sublimaation siirtopaperille sublimaatio -musteen avulla. Valmista nämä ennen sublimointitulostuksen aloittamista:

- Sublimaatiotulostin

- Sublimaatiomuste

- Sublimaatiopaperi

3. Voitteko käyttää DTF -paperia sublimointialusteella?

DTF -paperi on erityisesti suunniteltu käytettäväksi DTF -musteen kanssa, joka eroaa sublimointimusteesta. Siksi, DTF -paperia ei ole suositeltavaa käyttää sublimaatiosustetta, koska niillä on erilaisia ominaisuuksia ja ne vaativat erityisiä yhteensopivuuksia.

4. On sublimointipaperi sama kuin siirtopaperi?

Sublimaatiopaperi on eräänlainen siirtopaperi, joka on erityisesti suunniteltu sublimaatiotulostukseen. Sitä käytetään suunnittelun siirtämiseen substraattiin levittämällä lämpöä. Vaikka kaikki sublimaatiopaperit ovat siirtopapereita, Kaikkia siirtopapereita ei ole välttämättä suunniteltu sublimointitulostukseen.

5. Voitko käyttää DTF -jauhetta sublimointipaperilla?

DTF -jauhetta käytetään DTF -tulostusprosessissa suunnittelun ja substraatin välillä. Sitä ei tyypillisesti käytetä sublimointipaperilla, koska sublimointitulostus riippuu musteen kyvystä muuttaa kaasua ja läpäistä materiaalia, sen sijaan, että käytettäisiin jauhetta tarttumiseen.

6. Voitteko käyttää sublimaatio mustetta DTF -tulostukseen?

Ei, Sublimointia koskevaa mustetta ei voida käyttää suoraan DTF -tulostukseen. DTF -muste on erityinen tyyppinen muste, joka on muotoiltu DTF -tulostukseen, kun taas sublimointimuste on suunniteltu erilaiseen tulostusprosessiin.

7. On dtf -muste sama kuin sublimointia?

Ei, DTF -muste ei ole sama kuin sublimointia. Niillä on erilaisia koostumuksia ja ominaisuuksia, räätälöity heidän tulostustekniikkaansa. DTF -mustetta käytetään tulostamiseen elokuvalle, joka sitten siirretään vaatteisiin, Samalla.

Keskeinen take

Lopulta, DTF. Päätettäessä, mikä tulostusmenetelmä valita, Yritysten tulisi harkita heidän erityiset tulostustarpeet, budjetti, ja haluttu tulostuslaatu.

Kun tulostinvalmistajas jatkaa näiden tekniikoiden parantamista, Yritysten on pysyttävä ajan tasalla viimeisimmästä kehityksestä. Kunkin menetelmän etujen ja haittojen punnitseminen huolellisesti vaatimusten perusteella varmistaa, että valitset ihanteellisen digitaalisen tulostusratkaisun. Sekä DTF- että sublimaatiotulostus voivat tuottaa korkealaatuisia räätälöityjä tuotteita, kun ne toteutetaan oikein.

Valmis ottamaan tulostusoperaatiot seuraavalle tasolle? Yhdistä joukkueemme kanssa asiantuntijoiden arvioida yksilöllisiä tarpeitasi ja saada räätälöityjä suosituksia parhaasta DTF- tai Sublimation -asetuksesta yrityksesi tavoitteisiin.