Mukautetuista puhelinkuorista merkkigolfpalloihin, yksilöllisten tuotteiden kysyntä kasvaa nopeasti. Tämä suuntaus pakottaa yritykset ottamaan käyttöön tulostustekniikoita, jotka tarjoavat suuremman nopeuden, korkeampi laatu, ja laajempi materiaalien yhteensopivuus. Näiden teknologioiden joukossa, UV-tulostus erottuu kyvystään tulostaa suoraan monenlaisille pinnoille, mikä avaa uusia luovia ja kaupallisia mahdollisuuksia.

Tässä oppaassa kerrotaan, mitä UV-tulostimet ovat, niiden tärkeimmät edut, ja erilaisia tapoja käyttää niitä eri toimialoilla.

Mikä on UV-tulostin?

A UV-tulostin on digitaalinen tulostuslaite, joka käyttää ultravioletti (UV) kevyt, joka kovettaa musteen välittömästi erilaisten materiaalien pinnalle. Toisin kuin perinteiset liuotintulostimet – joissa muste tunkeutuu tai haihtuu materiaaliin – UV-tulostimet levittävät mustetta suoraan pinnalle.. UV-lamput kovettavat musteen välittömästi, muodostaen kiinteän aineen, kestävä kerros.

Tämä "UV-kovettuva" tekniikka tuottaa korkearesoluutioisia tulosteita, jotka tarttuvat hyvin muoviin, lasi, metalli, puu, nahka, akryyli, ja jopa joitain kankaita. Näin laajalla yhteensopivuudella, UV-tulostimet ovat korvaamattomia yrityksille, jotka haluavat räätälöidä tuotteita tai laajentaa tuotantokapasiteettiaan.

Nykypäivän markkinat ovat pääasiassa ominaisuuksia kolmenlaisia UV-tulostimia:

- UV-tasotulostimet

- UV DTF -tulostimet

- Hybridi UV-tulostimet

Jokainen palvelee erilaisia tarpeita liiketoimintamallista ja materiaalityypeistä riippuen.

UV-tulostuksen edut

Perinteisiin menetelmiin verrattuna, UV-tulostus tarjoaa useita vahvoja etuja:

1. Poikkeuksellinen monipuolisuus

UV-tulostimet voivat tulostaa lähes mille tahansa pinnalle – puulle, akryyli, lasi, nahka, silikoni, alumiini, ja enemmän. Tämän kyvyn ansiosta yritykset voivat laajentua lukemattomiin tuotekategorioihin.

2. Korkea tulostuslaatu

UV-teknologia tuottaa teräviä, elinvoimainen, ja korkearesoluutioisia kuvia. Koska muste pysyy pinnalla, ei ole verenvuotoa tai tahroja, tuloksena on teräviä yksityiskohtia ja täyteläisiä värejä.

3. Erinomainen Kestävyys

UV-kovettuva muste kestää erittäin hyvin naarmuuntumista, häipyminen, ja kosteutta. Tämä tekee UV-tulostuksesta ihanteellisen tuotteille, joita käsitellään usein tai altistetaan ulkona, kuten puhelinkuorille, opasteet, pullot, tai teollisia etikettejä.

4. Nopea ja tehokas tuotanto

Välitön kovettuminen tarkoittaa ei kuivumisaikaa, nopeuttaa tuotantoa dramaattisesti. Tämä tehokkuus on ratkaisevan tärkeää yrityksille, jotka käsittelevät suuria tilausmääriä tai nopeita toimituskuluja.

5. Ympäristöystävällinen

UV-musteet sisältävät vähän tai ei ollenkaan VOC-yhdisteitä (haihtuvat orgaaniset yhdisteet), tekee niistä turvallisempia sekä käyttäjille että ympäristölle – sopusoinnussa hyvin kasvavien kestävän kehityksen trendien kanssa.

UV-tulostimien sovellukset

UV-tulostuksen monipuolisuus tekee siitä arvokkaan monilla toimialoilla. Tässä on joitain suosituimmista sovelluksista:

Kampanjatuotteet & Yrityslahjat

Henkilökohtaiset promootiotuotteet ovat nopeasti kasvavat markkinat. UV-tulostimet tulostavat helposti logoja ja yksityiskohtaisia kuvioita kynille, avaimenperät, juomalasit, USB-asemat, golfpallot, ja enemmän – tuottaa eloisia ja kestäviä tuotteita pyynnöstä.

Kyltit ja visuaalinen grafiikka

UV-tulostus on erinomainen sekä sisä- että ulkokyltissä. Sen säänkestävät ominaisuudet tekevät siitä ihanteellisen:

- Liikkeen kyltit

- Bannerit

- Suuntaviivat

- POP (ostopisteessä) näytöt

Materiaalit kuten PVC, akryyli, ja puutukipalkkio, pitkäikäisiä kylttiratkaisuja.

Räätälöity elektroniikka & Tarvikkeet

Henkilökohtaisen elektroniikan yleistyessä, UV-tulostimia käytetään laajalti:

- Puhelinkotelot

- Kannettavan tietokoneen kannet

- Kuulokkeet

- Tekniset tarvikkeet

Kovettunut muste säilyttää ulkonäkönsä raskaassakin päivittäisessä käytössä.

Pakkaus & Prototyyppien tekeminen

UV-tulostimet voivat tulostaa suoraan pakkausmateriaaleille, kuten paperilaatikoille, tölkit, ja muoviastiat. Tämä mahdollistaa nopean, edullinen prototyyppien valmistus ja pieni erätuotanto ilman perinteisiä painokustannuksia tai pitkiä toimitusaikoja.

Sisustussuunnittelu & Kodin sisustus

Arkkitehdit ja suunnittelijat käyttävät nyt UV-tulostimia räätälöityihin sisustustuotteisiin, mukaan lukien:

- Seinätaide

- Koristeelliset laatat

- Huonekalupaneelit

- Lasi- ja akryylikyltit

Puulle painatus tarjoaa luonnollisen esteettisen, kun taas lasi ja akryyli tuottavat modernin, kiillotettu ilme.

Teolliset etiketit & Osamerkintä

Teollisissa olosuhteissa, kestävyys on välttämätöntä. UV-tulostimia käytetään pysyvien tarrojen ja merkintöjen tulostamiseen suoraan:

- Koneen osat

- Paneelit

- Työkalut

- Komponentit

Tulokset kestävät kemikaaleja, hankausta, ja korkeita lämpötiloja.

Tekstiili & Kankaan painatus (Viimeisin läpimurto)

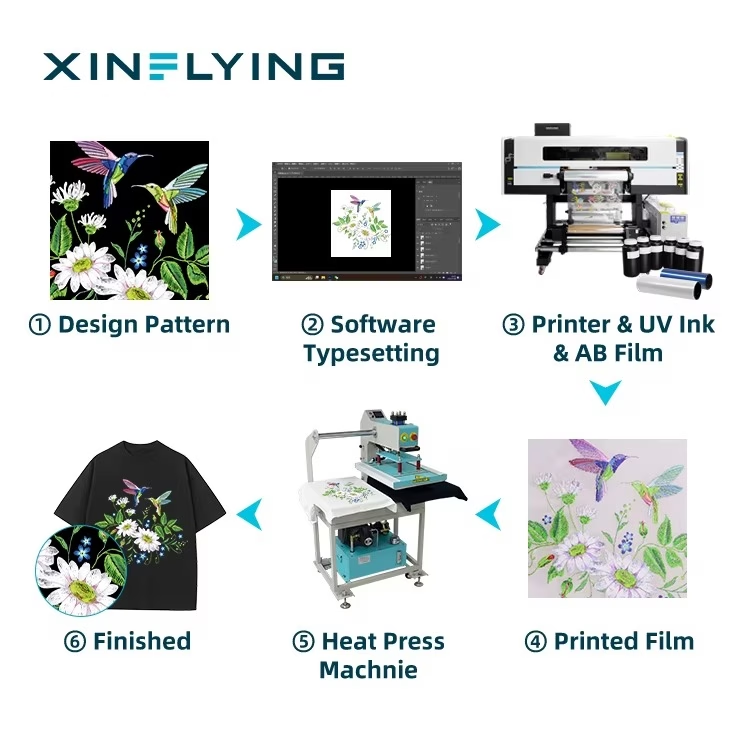

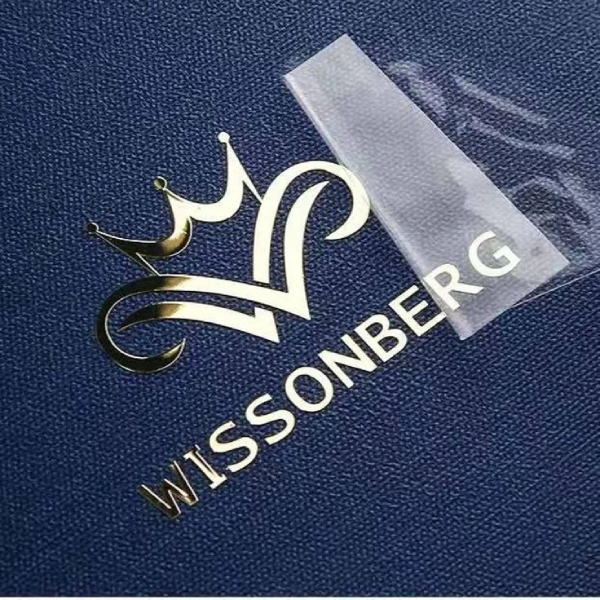

Yksi UV-tekniikan uusimmista kehityssuunnista on sen kyky painaa tekstiileille. Kuten korosti Xinflying, kehittynyt UV-tulostus voi luoda 3D, silikonimainen, kirjontatyyliset paikat kankaiden päällä. Nämä laastarit voidaan lämpöpuristaa paitojen päälle, laukut, hatut, kenkiä, ja enemmän – tarjoamalla palkkion, kuvioitu vaikutus, joka muistuttaa kirjontaa, mutta digitaalisella tarkkuudella ja nopeudella.

Tämä tekniikka on erityisen suosittu:

- Yrityksen logot

- Muotipaikat

- Räätälöidyt vaatesuunnittelut

Johtopäätös

UV-tulostus on mullistanut sen, mitä yritykset voivat luoda – ylittäen perinteisen painatuksen rajoitukset. Verrattoman monipuolisuudella, nopeus, kestävyys, ja materiaalien yhteensopivuus, UV-tulostimien avulla yritykset voivat tuottaa kaikkea mainostuotteista ja teknisistä lisävarusteista sisustukseen, prototyyppejä, ja vaatepaikat.

Yrityksille, jotka haluavat laajentaa tuotevalikoimaa, lisätä tehokkuutta, ja tuottaa korkealaatuisia tulosteita, UV-tulostuksen tutkiminen on luonnollinen seuraava askel. UV-teknologian käyttöönotto voi avata uusia tulovirtoja ja antaa yrityksellesi vahvan kilpailuedun.

Jos olet valmis tutustumaan UV-tulostusratkaisuihin, Xinflying tarjoaa luotettavia, korkealaatuiset UV-laitteet, jotka on suunniteltu tukemaan sekä startup-yrityksiä että vakiintuneita painoyrityksiä.