مقدمة

في السنوات الأخيرة, customization technologies have shifted away from traditional substrate-dependent printing methods toward more versatile, transfer-based solutions. Among these, UV DTF printing has emerged as a hybrid process that combines ultraviolet curing technology with direct-to-film workflows. Unlike conventional DTF or UV flatbed printing, UV DTF printers enable durable, high-resolution graphics to be transferred onto rigid and irregular surfaces without direct ink deposition on the final object.

This article examines UV DTF printers from a technical and operational perspective. It focuses on the benefits of the technology, its functional distinctions from other digital printing systems, and the contexts in which UV DTF printers provide measurable value. References to uv dtf sticker printer التطبيقات, comparative discussions related to the best dtf printers, and observations commonly found in dtf printer reviews are incorporated to provide a balanced and realistic overview.

Understanding UV DTF Printing Technology

UV DTF printing is a two-stage process. أولاً, a UV-curable ink image is printed onto a specialized release film (فيلم أ). The ink is instantly cured using ultraviolet light, forming a solid, flexible ink layer. A laminating adhesive film (فيلم ب) is then applied, creating a transferable sticker structure. Once laminated, the graphic can be applied to a target surface by pressure alone, after which the carrier film is removed.

Unlike water-based DTF systems, UV DTF printing does not require heat pressing. This distinction fundamentally changes the range of compatible substrates and reduces thermal stress on both materials and equipment.

Key Advantages of UV DTF Printers

1. Material Versatility Beyond Textiles

One of the most significant benefits of UV DTF printers is their ability to decorate non-porous and irregular surfaces. While traditional DTF printing is primarily optimized for textiles, UV DTF systems excel in applications involving:

- Glass and acrylic

- الأسطح المعدنية

- Plastics and polymers

- Wood with sealed finishes

- Coated ceramics

This capability positions the uv dtf sticker printer as a solution for industries such as promotional products, لافتات, consumer electronics branding, and packaging prototyping.

2. No Heat Press Requirement

The absence of a heat press simplifies the production workflow. Heat-sensitive materials, such as thin plastics or coated surfaces, can be decorated without deformation. This also reduces energy consumption and minimizes operator training complexity, particularly in small production environments.

From an operational standpoint, this feature frequently appears as a positive point in professional dtf printer reviews, especially when UV DTF printers are compared with textile-focused DTF systems.

3. High Adhesion and Durability

UV-cured inks form a polymerized layer with strong mechanical bonding properties. When transferred correctly, the resulting graphic exhibits:

- High scratch resistance

- Chemical resistance to mild solvents

- Long-term color stability under indoor conditions

While UV DTF prints may not fully replace industrial UV direct printing for extreme outdoor exposure, they provide sufficient durability for most commercial and consumer applications.

4. Precision and Image Fidelity

UV DTF printers operate with fine droplet control and multi-layer ink deposition, often including white ink and varnish layers. This enables:

- Sharp text reproduction

- High opacity on dark substrates

- Embossed or textured visual effects

Compared to many of the best dtf printers designed for fabric, UV DTF printers prioritize edge definition and surface detail over ink penetration, reflecting their different end-use objectives.

UV DTF Printers vs. Traditional DTF Printers

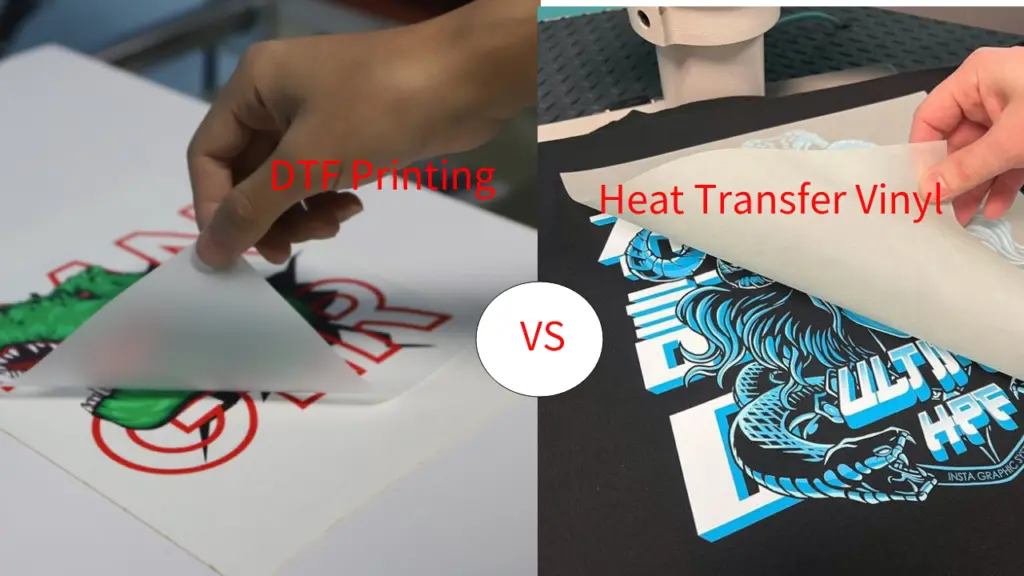

Although both technologies use transfer films, their engineering goals differ substantially.

Traditional DTF printers rely on water-based pigment inks and thermoplastic powder adhesives, followed by heat activation. طابعات الأشعة فوق البنفسجية DTF, by contrast, use UV-curable inks and pressure-activated adhesive films.

| Aspect | Traditional DTF | الأشعة فوق البنفسجية دي تي إف |

|---|---|---|

| Primary substrates | Fabrics | Rigid & semi-rigid |

| Ink curing | حرارة | أشعة فوق البنفسجية |

| Adhesion method | الصحافة الحرارة | Pressure transfer |

| نَسِيج | ناعم, fabric-integrated | Raised, sticker-like |

This distinction is often emphasized in dtf printer reviews, where UV DTF printers are evaluated not as replacements, but as complementary systems.

Workflow Efficiency and Production Scalability

UV DTF printing supports batch production with minimal setup changes. Once a design is prepared, multiple stickers can be printed, laminated, and stored for later application. This decoupling of printing and application stages improves workflow flexibility.

For businesses operating multiple customization channels, UV DTF printers allow centralized production of transfers that can be applied on demand, reducing idle machine time and increasing output predictability.

Maintenance and Operational Considerations

UV DTF printers introduce different maintenance requirements compared to water-based DTF systems. UV inks do not dry through evaporation, reducing the risk of nozzle clogging. لكن, they require:

- Regular UV lamp inspection

- Controlled ink handling to avoid premature curing

- Proper ventilation due to photoinitiator compounds

In professional dtf printer reviews, users frequently note that UV DTF printers trade daily ink agitation routines for more structured preventive maintenance schedules.

Application Scenarios for UV DTF Printers

المنتجات الترويجية

Logos and branding elements can be applied to drinkware, أغلفة الجوال, power banks, and gift items without specialized fixtures.

Industrial Labeling

UV DTF transfers are suitable for short-run equipment labels or control panel markings where traditional screen printing is impractical.

Retail Customization

In-store or near-store customization becomes feasible due to the simplified application process and minimal equipment footprint.

Evaluating UV DTF Printers in the Market

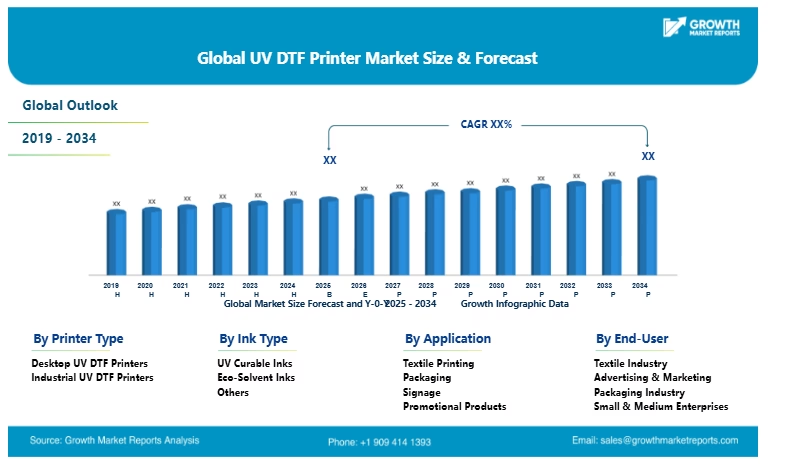

According to our latest research, ال UV DTF Printer market size reached USD 1.67 مليار في 2024, demonstrating robust momentum in the digital printing sector. The market is growing at a CAGR of 12.8% and is projected to reach دولار أمريكي 4.41 مليار من قبل 2033 (مصدر).

The growth is fueled by:

- Increasing adoption of high-quality, versatile printing solutions

- Rising demand for منتجات مخصصة across textiles, التغليف, and promotional industries

- Businesses seeking cost-effective ways to enhance product personalization

When assessing UV DTF printers, buyers often compare them against the best dtf printers in terms of cost, output quality, والموثوقية. لكن, direct comparison can be misleading due to differing use cases.

Relevant evaluation criteria include:

- Ink layer consistency

- White ink opacity

- Adhesive film performance

- Long-term UV lamp stability

These factors are commonly discussed in technical dtf printer reviews, particularly those written by commercial users rather than entry-level operators.

Limitations and Trade-Offs

Despite their advantages, UV DTF printers are not without constraints:

- Higher consumable costs compared to water-based inks

- Limited flexibility on highly textured surfaces

- Raised print feel, which may not suit all design aesthetics

Understanding these limitations is critical for realistic adoption planning.

The Role of UV DTF in the Future Printing Landscape

UV DTF printers occupy a niche between flatbed UV printing and textile-focused DTF systems. As demand grows for short-run, customized, non-fabric products, UV DTF technology is likely to expand rather than replace existing methods.

From an industry perspective, UV DTF printers represent an incremental evolution rather than a disruptive replacement—offering targeted benefits where traditional printing methods face physical or economic constraints.

خاتمة

UV DTF printers provide a technically distinct solution within the digital printing ecosystem. Their ability to transfer UV-cured graphics onto a wide range of rigid substrates, without heat or direct printing, addresses specific production challenges that conventional systems cannot efficiently solve.

For businesses evaluating a uv dtf sticker printer, understanding how these systems differ from the best dtf printers for textiles—and how they are assessed in detailed dtf printer reviews—is essential. When applied within the appropriate scope, UV DTF printers offer precision, متانة, and operational flexibility that align well with modern customization demands.