Forrás: https://www.pinterest.com.au

A szublimációs nyomtatás egy népszerű nyomtatási technika, amelyhez speciális szublimációs nyomtatóra van szükség a kiváló minőség eléréséhez, hosszú élettartamú nyomatok különféle hordozókra. A megfelelő szublimációs nyomtató kiválasztása ijesztő feladat lehet, annyi gyártó és modell elérhető a piacon.

Ez a szublimációs nyomtatók teljes útmutatója mindent tartalmaz, amit tudnia kell, a rendelkezésre álló különböző típusú nyomtatóktól a választás során figyelembe veendő kulcsfontosságú tényezőkig. Akár kezdő, akár tapasztalt szublimációs nyomtató gyártója, ez az útmutató segít kiválasztani az igényeinek megfelelő nyomtatót és elérni a kiváló minőséget, szakmai eredményeket.

Mi az a szublimációs nyomtatás?

Forrás: https://www.pinterest.com.au

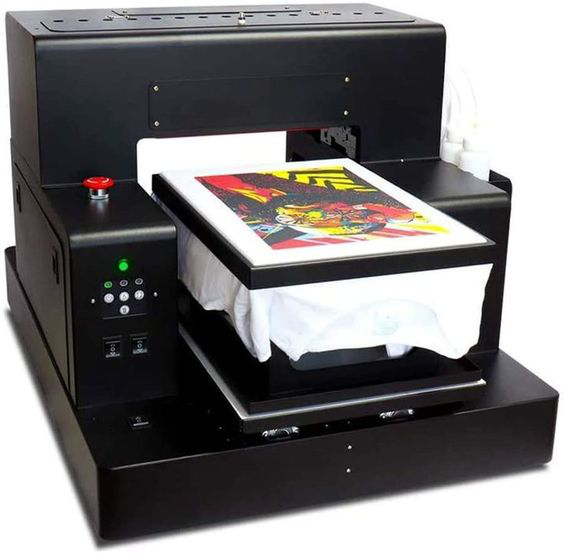

Szublimációs nyomtatás egy digitális nyomtatási technika, amely magában foglalja a festék hordozóra történő átvitelét (például szövet vagy műanyag) hő és nyomás segítségével. A folyamat magában foglalja a kívánt kép nyomtatása speciális transzferpapírra szublimációs tintával, amely egy speciális típusú tinta, amely szilárd halmazállapotból gázzá tud átalakulni anélkül, hogy folyékony fázison menne keresztül.

A transzferpapírt ezután a hordozóra helyezik, és hőprés segítségével hőnek és nyomásnak vetik alá. Emiatt a szublimációs tinta gázzá válik, amely azután átjárja a hordozó rostjait és tartósan beágyazódik az anyagba. Az eredmény egy kiváló minőségű, élénk és hosszan tartó nyomat, amely ellenáll a fakulásnak és a hámlásnak.

A szublimációs nyomtatást általában használják egyedi minták készítése ruházaton, mint például a pólók, kalapok, és mezek, valamint promóciós cikkeken, például bögrékön, alátét, és telefonos tokok. Népszerű választás poliészter szövetekre történő nyomtatáshoz, de más anyagokon, például kerámián is használható, fém, és fa.

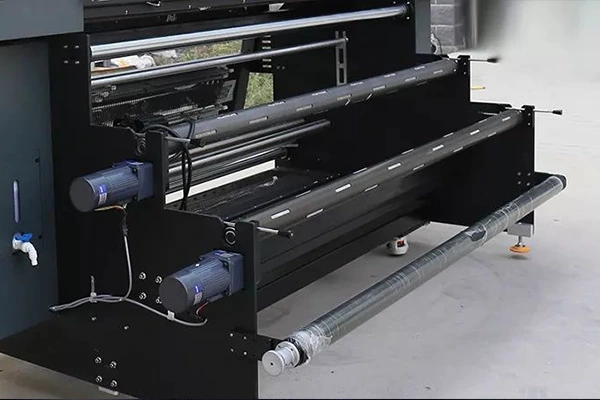

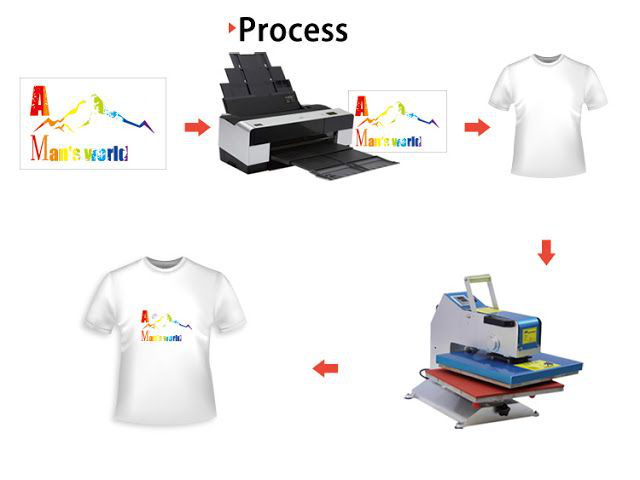

Szublimációs nyomtatási folyamat

Forrás: https://www.pinterest.com.au

A szublimációs nyomtatási folyamat általában a következő lépésekből áll:

1. Tervezés

Hozzon létre vagy válasszon egy mintát, amelyet nyomtatni szeretne a hordozójára. Ez történhet grafikai tervező szoftverrel vagy előre elkészített tervek vásárlásával.

2. Nyomtatás

Nyomtassa ki a mintát szublimációs transzferpapírra egy speciális nyomtatóval, amely kompatibilis a szublimációs tintával.

Az aljzat előkészítése: Melegítse elő a hőprést az alapfelületnek megfelelő hőmérsékletre. Helyezze az aljzatot a hőprésre, és néhány másodpercig előnyomja, hogy eltávolítsa a nedvességet és a ráncokat.

3. A transzferpapír elhelyezése

Helyezze a nyomtatott transzferpapírt nyomtatott oldalával lefelé a hordozóra, ügyelve arra, hogy középen legyen, és a minta az aljzat felé néz. Rögzítse a transzferpapírt a helyére hőálló szalaggal.

4. Hő és nyomás alkalmazása

Zárja le a hőprést, és alkalmazza a megfelelő mennyiségű hőt és nyomást az ajánlott ideig. A hő és a nyomás hatására a szublimációs tinta gázzá válik, és áthatja a hordozó rostjait., tartós kötelék létrehozása.

5. Végső

Ha letelt az idő, nyissa ki a hőprést, és távolítsa el a hordozót és a transzferpapírt. Hagyja lehűlni a hordozót, és távolítsa el a transzferpapírt. A mintát most véglegesen be kell ágyazni az aljzatba.

6. Minőségellenőrzés

Vizsgálja meg az aljzatot, hogy nincsenek-e rajta hibák vagy hibák, és végezze el a szükséges módosításokat vagy javításokat.

Szublimációs nyomtatáshoz használható szubsztrátumok

Forrás: https://inkteknigeria.com

A szublimációs nyomtatás többféle hordozón használható, de leginkább olyan anyagokhoz illik, amelyek poliészterből készültek vagy poliészter bevonattal rendelkeznek. Íme néhány elterjedt hordozó, amely szublimációs nyomtatáshoz használható:

- Ruházat

A szublimációs nyomtatást általában poliészter alapú szövetekre nyomtatják, beleértve a pólókat, mezek, kalapok, és egyéb ruházati cikkek.

- Kerámia

A szublimációs nyomtatással kerámia bögrékre nyomtathatók minták, lemezeket, és csempe.

- Fém

A szublimációs nyomtatással alumíniumra nyomtathatók, sárgaréz, és egyéb fémfelületekre.

- Műanyagok

A szublimációs nyomtatással mintákat nyomtathatunk műanyag tárgyakra, mint például a telefontokok, kulcstartó, és vizes palackok.

- Üveg

A szublimációs nyomtatás üvegtárgyakra minták nyomtatására használható, például képkeretek és dísztárgyak.

- Faipari

A szublimációs nyomtatással fa felületekre nyomtathatók minták, mint például táblák és jelek.

Tinta és transzferpapír: Hogyan válasszuk ki a megfelelőket

Forrás: https://www.babbel.com

Íme néhány tipp a megfelelő tinta és transzferpapír kiválasztásához a kívánt szublimációs nyomtatási alkalmazáshoz:

Vegye figyelembe az aljzatát

A nyomtatni kívánt hordozó típusa nagy szerepet játszik a használni kívánt tinta és transzferpapír típusának meghatározásában.. Például, ha poliészter alapú anyagokra tervez nyomtatni, olyan tintára és transzferpapírra lesz szüksége, amelyet kifejezetten poliészterhez terveztek.

Ellenőrizze a nyomtató kompatibilitását

Győződjön meg arról, hogy a kiválasztott tinta és transzferpapír kompatibilis a nyomtató modelljével. Egyes nyomtatóknak bizonyos típusú tintára vagy transzferpapírra lehet szükségük a kiváló minőségű nyomatok készítéséhez.

Fontolja meg a színskálát

A színskála a tinta által előállítható színtartományra vonatkozik. Keressen olyan tintát és transzferpapírt, amely széles színskálát kínál, mivel így élénkebb és pontosabb színeket érhet el nyomataiban.

Keresse a Gyors száradási időket

Egyes szublimációs tinták hosszabb száradási időt igényelhetnek, mielőtt készen állnak a hőátadásra. A gyorsabb gyártási idők érdekében, keressen olyan tintát, amely gyors száradási időt biztosít.

Válassza a Kiváló minőségű transzferpapírt

A transzferpapír minősége nagy hatással lehet a nyomatok minőségére. Keressen olyan transzferpapírt, amely nagy felszabadulási sebességgel rendelkezik, és kifejezetten szublimációs nyomtatáshoz készült.

Fontolja meg a bevonási lehetőségeket

Egyes transzferpapírok olyan bevonattal rendelkeznek, amely javítja a tinta felszívódását és az átviteli minőséget. Keressen olyan transzferpapírt, amelynek bevonata kompatibilis a tintával és a hordozóval.

Keresse az Értéket

Kiválasztáskor vegye figyelembe a tinta és a transzferpapír költségét, de ügyeljen arra is, hogy kiváló minőségű anyagokat válasszon, amelyek a kívánt eredményt hozzák.

Előnyök és hátrányok

Forrás: https://www.shutterstock.com

Előnyök

- Kiváló minőségű nyomatok: A szublimációs nyomtatás kiváló minőséget eredményez, vibráló, és hosszan tartó nyomatok, amelyek ellenállnak a fakulásnak és a hámlásnak.

- Aljzatok széles választéka: A szublimációs nyomtatás többféle hordozón használható, beleértve a poliészter alapú szöveteket, kerámia, fémek, műanyagok, és több.

- Testreszabás: A szublimációs nyomtatás lehetővé teszi a tervek testreszabását, így ideális személyre szabott ajándékokhoz, ruházat, és promóciós tételek.

- Nincsenek maradékok: A szublimációs nyomtatás nem hagy nyomot a hordozón, tisztább és környezetbarátabb nyomtatási módszerré téve.

- Költséghatékony: A szublimációs nyomtatás költséghatékony nyomtatási módszer, főleg kisebb mennyiségeknél, mivel a nyomtatási költség a mennyiség növekedésével csökken.

Hátrányok

- Korlátozott színválaszték: A szublimációs nyomtatás korlátozott színválasztékkal rendelkezik, mivel csak olyan színeket tud előállítani, amelyek a kiválasztott tinta színskáláján belül vannak.

- Korlátozott szubsztrátum lehetőségek: A szublimációs nyomtatás csak poliészterből készült vagy poliészter bevonattal ellátott hordozókra alkalmas, ami korlátozza a felhasználható hordozók körét.

- Berendezés költsége: A szublimációs nyomtatás speciális felszerelést igényel, beleértve aszublimációs nyomtató, hőprés, valamint speciális tinta és transzferpapír, ami drága lehet.

- Tanulási görbe: A szublimációs nyomtatás bizonyos készségeket és tapasztalatokat igényel a legjobb eredmény elérése érdekében, és van egy tanulási görbe a technika elsajátításában.

- Sötét aljzatokhoz nem alkalmas: A szublimációs nyomtatás nem működik jól sötét hordozón, mint aszublimációs tinta áttetsző, és nem jelenik meg jól sötét színeken.

Kreatív lehetőségek a szublimációs nyomtatással

Forrás: https://blog.bookbaby.com

A szublimációs nyomtatás a kreatív lehetőségek széles skáláját kínálja, így népszerű választás személyre szabott ajándékok számára, ruházat, és promóciós tételek. Íme néhány kreatív lehetőség a szublimációs nyomtatással:

- Egyedi ruházat

A szublimációs nyomtatás lehetővé teszi a teljes körű nyomtatást poliészter alapú szövetekre, így ideális egyedi pólók készítéséhez, mezek, és egyéb ruházati cikkek színes mintákkal.

- Személyre szabott ajándékok

A szublimációs nyomtatással személyre szabott ajándékok készíthetők, mint például a bögrék, alátét, telefontokok, és a fotókeretek. A lehetőségek végtelenek, és bármit kinyomtathat a családi fényképektől a kedvenc idézetekig.

Promóciós cikkek: A szublimációs nyomtatás ideális promóciós cikkek készítéséhez, mint például a tollak, kulcstartó, és vizes palackok, céged logójával vagy üzenetével.

- Jelzés

A szublimációs nyomtatás használható feliratok készítésére, például transzparensek és zászlók, eseményekhez, szakkiállítások, és a vállalkozások.

- Otthoni dekoráció

A szublimációs nyomtatással egyedi lakberendezési tárgyakat készíthetünk, mint például díszpárnák, falművészet, és asztali futók.

- Sporteszközök

A szublimációs nyomtatással személyre szabott sportfelszerelések készíthetők, mint például a futballlabdák, kosárlabda, és frizbik.

- Kisállat kiegészítők

A szublimációs nyomtatással személyre szabott kisállat-kiegészítők készíthetők, mint például a kisállat-címkék és a bandanna.

- Újdonságok

A szublimációs nyomtatással egyedi újdonságokat hozhatunk létre, mint például a rejtvények, kártyázás, és mágnesek.

Gyakori hibák, amelyeket el kell kerülni

Forrás: https://www.dreamstime.com

A textíliákon történő szublimációs nyomtatás kissé bonyolult lehet, és számos gyakori hiba előfordulhat. Íme néhány hiba, amelyet el kell kerülni a textíliákra történő szublimációs nyomtatás során:

- Nem megfelelő szövet használata

A szublimációs nyomtatás a legjobban poliészter alapú anyagokon működik, ezért ügyeljen arra, hogy legalább olyan anyagot válasszon 50% poliészter. Kerülje a túl rugalmas vagy magas pamuttartalmú anyagok használatát, mivel nem biztos, hogy jó eredményeket hoznak.

- Nem készíti elő megfelelően az anyagot

Nyomtatás előtt, ügyeljen arra, hogy előnyomja az anyagot, hogy eltávolítsa a nedvességet és a ráncokat. Ez biztosítja, hogy a szövet sima és készen álljon a tinta befogadására.

- Nem használ elegendő nyomást

A jó átvitel érdekében, az anyagot kellő nyomással kell nyomni. Ügyeljen arra, hogy a hőprés nyomását az aljzathoz javasolt beállításoknak megfelelően állítsa be.

- Nem a megfelelő tintát használja

Ügyeljen arra, hogy olyan szublimációs tintát válasszon, amelyet kifejezetten textilekhez való használatra terveztek. Nem megfelelő tinta használata rossz átviteli minőséget és színpontosságot eredményezhet.

- Nem megfelelő transzferpapírt használ

Válasszon olyan transzferpapírt, amelyet kifejezetten textilekhez való használatra terveztek. Nem megfelelő transzferpapír használata rossz átviteli minőséget és színpontosságot eredményezhet.

- Nem használja a megfelelő hőmérsékletet és időt

Ügyeljen arra, hogy a hőpréshez ajánlott hőmérséklet- és időbeállításokat használja. Túl kevés vagy túl sok idő vagy hő használata rossz átviteli minőséget és színpontosságot eredményezhet.

Következtetés

Forrás: https://www.pinterest.com.au

Következtetésképpen, A megfelelő szublimációs nyomtató kiválasztása kulcsfontosságú a kiváló minőség eléréséhez, hosszú élettartamú nyomatok különféle hordozókra. Olyan tényezők figyelembevételével, mint a nyomtató típusa, tinta típusa, színes skála, és lapméret, kiválaszthatja az igényeinek leginkább megfelelő szublimációs nyomtatót.

Továbbá, fontos, hogy jó minőséget válasszunk szublimációs papír amely kompatibilis a nyomtatóval és a hordozóval. Azoknak, akik alternatívát keresnek a szublimációs nyomtatás helyett, DTF nyomtatós és DTG nyomtatós szintén megfontolandó lehetőségek. A szublimációs nyomtatókhoz szóló teljes útmutatóban található információkkal és tippekkel, magabiztosan kiválaszthatja az igényeinek megfelelő nyomtatót, és professzionális minőségű nyomatokat készíthet, amelyek lenyűgözőek.