A szövetnyomtatás népszerűsége az elmúlt években megugrott, ahogy egyre többen igyekszik személyessé tenni textíliáit. A szövetnyomtatók megjelenésével, a folyamat minden eddiginél hozzáférhetőbbé és kényelmesebbé vált. Ebben az átfogó útmutatóban, mélyen elmerülünk a textilnyomtatás birodalmában, technikáinak feltárása és számos előnyének kiemelése. Akár tapasztalt művész vagy, akár csak most indulsz kreatív utazásodra, ez az útmutató úgy készült, hogy minden szükséges információt megadjon kreativitásod kibontakoztatásához és félelmetes szövetnyomatok készítéséhez.

Mi az a szövetnyomtatás?

A szövetnyomtatás az a folyamat, amikor a mintákat vagy mintákat speciális nyomtatási technikák segítségével átviszik a szövetre. Ez magában foglalja a pigmentek felvitelét, színezékek, vagy tintával a szövet felületére, hogy élénk és részletgazdag mintákat készítsen. A szövetnyomtatás bonyolult műalkotásokat tesz lehetővé, végtelen színlehetőség, és a minta pontos elhelyezése a szöveten.

A szövetnyomtatás típusai

Mielőtt belevetnénk magunkat a textilnyomtatás fortélyaiba, létfontosságú, hogy megértsük ennek a művészeti formának a lényegét. A lényegében, A szövetnyomtatás magában foglalja a minták szövetekre történő átvitelét, egyedi minták és látványelemek létrehozása. A szövetnyomtatásban különféle módszereket és szövetnyomtatókat használnak, mindegyiknek megvan a maga sajátos jellemzői.

Szitanyomás

Szitanyomás, más néven selyemszűrő, az egyik legrégebbi és leghagyományosabb szövetnyomtatási módszer. Ez magában foglalja a hálós stencil használatát, lényegében egy képernyő, amelyen keresztül a tintát a szövetre nyomják a kívánt minta létrehozásához.

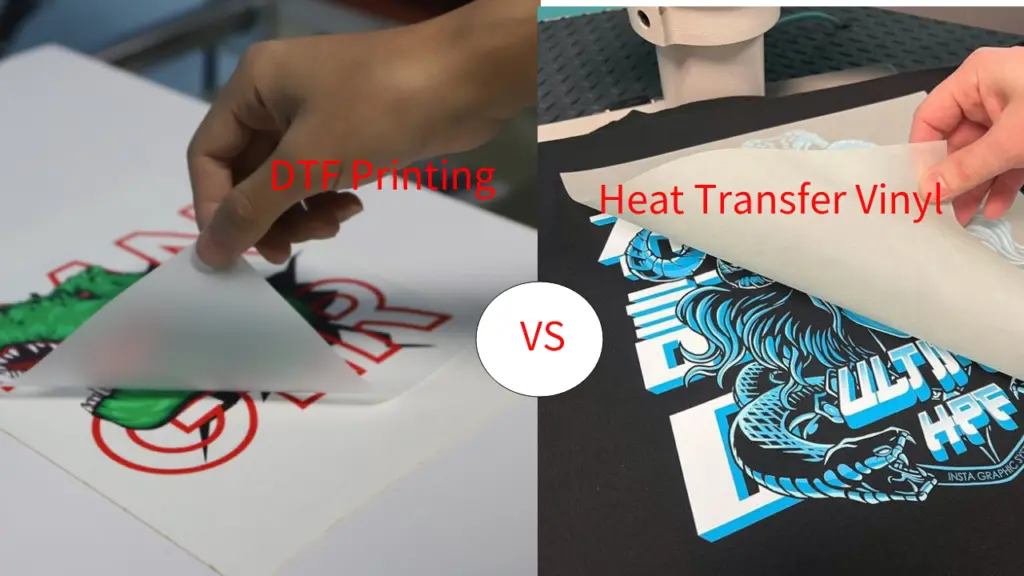

Hőátviteli nyomtatás

A hőátadó nyomtatás hőt alkalmaz a minták szövetre történő átviteléhez. Ebben a folyamatban, speciális tintát nyomtatnak a transzferpapírra, majd hő hatására a szövetre viszik, élénk és tartós nyomatokat eredményez.

Digitális textilnyomtatás

Digitális textilnyomtatás, másrészről, egy viszonylag modern és hatékony technika, amely digitális technológiát használ a minták szövetre történő nyomtatására. Ez a fajta textilnyomtató nagyobb pontosságot kínál, rugalmasság, és a bonyolult részletek könnyed reprodukálásának képessége, mint például széles formátumú szublimációs nyomtató és közvetlenül a Graments nyomtatóra. Ez volt a textilnyomtatás és a leginkább ajánlott textilnyomtatási technikák jövője.

| Módszer | Szitanyomás | Hőátviteli nyomtatás | Digitális textilnyomtatás |

| Folyamat | Stencileket és szitákat használ a tervezéshez. | Hőt és nyomást használ a tervezéshez. | Számítógépes szoftvert használ a tervezés létrehozásához és nyomtatásához. |

| Költség | Költséghatékony lehet nagy futásokhoz. | Kisebb futásoknál költséghatékony lehet. | A költségek magasabbak lehetnek, de lehetővé teszik a teljes testreszabást. |

| Sokoldalúság | A lapos felületekre korlátozva. | Különféle anyagokra és formákra alkalmazható. | Sokféle anyagon alkalmazható. |

| Tartósság | Nagy tartósság, a kialakítás ellenáll az ismételt mosásnak. | Módszertől függően változik (A vinil tovább tart, mint a szublimáció). | Megfelelő utófeldolgozás esetén nagy tartósság. |

| Sebesség | Ideális tömeggyártáshoz a sebesség miatt. | Lassabb, mint más módszerek. | A tervezés bonyolultságától függően változik, általában lassabb, mint a szitanyomás. |

| Részlet | Hiányozhatnak a finomabb részletek a képernyőháló miatt. | A hő és a nyomás miatt apró részletek hiányozhatnak. | Nagyon bonyolult részleteket képes rögzíteni, mivel közvetlenül digitális fájlokból nyomtat. |

| Környezet | A használt tintától függően erős vegyszereket tartalmazhat. | A hőátadás sok energiát fogyaszthat, és olyan vinilből állhat, amely biológiailag nem lebomlik. | Vízbázisú tintákat használ, amelyek kevésbé károsak a környezetre. |

A szövetnyomtatás első lépései 4 Egyszerű lépések

Megszerzése a szövet nyomtató az első lépés a szövetnyomtatás izgalmas világába. Kulcsfontosságú, hogy megbízható digitális textilnyomtatókat találjunk, és megértse a jellemzőket, specifikációk, és a piacon elérhető különféle ruhanyomtatók kompatibilitását. Következő, olyan anyagokra lesz szükséged, mint pl szövet, tinta, hőprés, és nyomtatószoftver. Emlékezik, a szervezett munkaterület fokozza kreatív teljesítményét.

A nyomatok tervezése

A textilnyomtatás tökéletes utat nyit kreativitásod kibontakoztatásához. Az inspiráció bárhonnan jöhet, legyen az a természet, építészet, vagy akár egy szép verset. A különböző tervezési technikák megismerése és a digitális tervek elkészítése ragyogó eredményekhez vezethet. A jól előkészített formatervezés minőségi nyomtatást biztosít.

Anyaga nyomtatásra való előkészítése

A szövet összetételének megértése kulcsfontosságú. Egyes szövetek jobban reagálnak a nyomtatásra, mint mások, megkívánja, hogy megfelelően mosogassa és előkészítse őket. Az anyag előkezelése jelentősen megváltoztathatja a végső eredményt. A megfelelő módszerek használata garantálja a hosszú élettartamot és a nyomtatási minőséget.

Nyomtatás szövetre

Most jön a szórakoztató rész, nyomtatás. Bár elsőre idegtépő tud lenni, A lépésenkénti utasítások követésével tökéletes nyomatot kaphat. A nyomtatási problémák elhárítása türelmet igényel. azonban, gyakorlattal, megtanulná, hogyan biztosíthatja a maximális élénkséget és színpontosságot.

Nyomtatott szövetek kikészítése és gondozása

A nyomtatás utáni kezelések javítják a szövetnyomat megjelenését, és az élettartamukhoz is hozzájárulhatnak. A nyomatok szárítása és hőkezelése elengedhetetlen ahhoz, hogy a nyomatok mosásállóak legyenek. Emlékezik, egy kis odafigyeléssel a kezelés és a tárolás során hosszabb ideig megőrizheti nyomtatott szöveteinek szépségét.

A szövetnyomtatás alkalmazásainak feltárása

A szövetnyomtatási technológia forradalmasította azt a módot, ahogyan kreativitásunkat és dizájnunkat kifejezhetjük különféle textilfelületeken. Akár divattervező vagy, lakberendező, foltvarrás rajongó, vagy valaki, aki rajong a kézművességért, a szövetnyomtatás a lehetőségek világát nyitja meg. Ebben a szakaszban, belemerülünk a textilnyomtatás különböző alkalmazásaiba, és abba, hogy miként javíthatja a különféle érdeklődési területeket.

Divat- és ruházati tervezés

A textilnyomtatás a divat- és ruhatervezés terén nélkülözhetetlen eszközzé vált. Lehetővé teszi a tervezőknek, hogy életre keltsék egyedi elképzeléseiket azáltal, hogy élénkséget adnak át, részletes minták a szövetekre. Szövet nyomtatóval, a tervezők különféle textil anyagokkal kísérletezhetnek, mint pl pamut, selyem, vagy akár szintetikus keverékek, ruházati stílusok és preferenciák széles skálájának kiszolgálása. Az egyedi ruhadarabok készítésétől a bonyolult minták kiegészítőkre való nyomtatásáig, a szövetnyomtatás lehetővé teszi a tervezők számára, hogy szabadjára engedjék kreativitásukat, és valami igazán kivételes dolgot kínáljanak vásárlóinak.

Lakberendezés és belsőépítészet

A szövetnyomtatás jelentős hatással van a lakberendezés és a lakberendezés világára. Egyedi minták szövetekre való nyomtatásának lehetőségével, a lakberendezők egyedi függönyöket készíthetnek, kárpitozott bútorok, vagy akár személyre szabott ágyneműt. A szövetnyomtatás lehetővé teszi a lakástulajdonosok számára, hogy könnyedén személyessé tegyék életterüket. Útvonalakat nyit meg az összetartás megteremtéséhez, tetszetős belső terek, ahol az ember valóban kifejezheti stílusát és személyiségét.

Foltvarrás és textilművészet

A foltvarrás és a textilművészet kedvelői kreatív törekvéseik miatt a textilnyomtatást is magukévá tették. A hagyományos foltvarrás magában foglalja a különféle szövetfoltok összevarrását, hogy szépet hozzon létre, bonyolult minták. Szövetnyomtatás beépítésével, a foltvarrók magasabb szintre emelhetik művészetüket. Bonyolult mintákat tudnak nyomtatni, képeket, vagy akár személyes fényképeket szövetre, egyedi árnyalatot adva paplan kreációikhoz. A textilnyomtatás lehetővé teszi a művészek számára, hogy különféle textilmintákkal és színekkel kísérletezzenek, végtelen lehetőségeket biztosítva a foltvarrás és a textilművészet világában.

Egyedi ajándékok és kézműves termékek

A szövetnyomtatás végtelen lehetőséget kínál személyre szabott ajándékok és kézműves termékek készítésére. Legyen szó személyre szabott hordtáskáról, személyre szabott konyhai kötény, vagy egy egyedi szövet fali alkotás, szövetnyomtatás lehetővé teszi az egyének számára, hogy értelmes alkotást hozzanak létre, egyedi tárgyak. Fényképek nyomtatásával, idézetek, vagy minták szöveten, az emberek személyessé tehetik ajándékaikat, amelyet szeretteik nagyra értékelnek. Továbbá, a szövetnyomtatás lehetőséget ad egyedi tárgyak készítésére, mint például a szövet ékszerek, kitömött játékok, vagy díszpárnák, lehetővé teszi az egyének számára, hogy felfedezzék kreativitásukat és kézzel készített kincseket hozzanak létre.

Tippek a szövetnyomtatás sikeréhez

A textilnyomtatás kifizetődő és kreatív mesterség lehet, lehetővé teszi egyedi tervezésének életre keltését különböző szöveteken. azonban, mint minden kreatív törekvés, a kihívásokkal együtt járhat. Ebben a szakaszban, feltárunk néhány értékes tippet a szövetnyomtatás gyakori kihívásainak leküzdéséhez, és útmutatást adunk képességeinek bővítéséhez, stílusod fejlesztése, és reklámozza a szövetnyomatait.

Készítse elő megfelelően az anyagot

Nyomtatás előtt, győződjön meg róla, hogy az anyag tiszta, száraz, és mentes minden ránctól és gyűrődéstől. Ez sima és egyenletes nyomtatást biztosít.

Tesztelje a szövet és a nyomtató beállításait

Kísérletezzen különböző anyagokkal, hogy meghatározza a nyomtatója számára legjobb beállításokat. Változók, például hőmérséklet beállítása, tinta sűrűsége, és a nyomtatási sebesség nagyban befolyásolhatja a végeredményt.

Cím tinta vérzés

Hogy a színek ne vérezzenek egymásba, nyomtatás előtt használjon szövetalapozót vagy előkezelő oldatot. Ez elősegíti, hogy a tinta hozzátapadjon a szövetszálakhoz, élesebb és élesebb nyomatokat eredményez.

Következtetés

A textilnyomtatás kétségtelenül izgalmas és kifizetődő művészet. Ez nem csak abban segít, hogy felszabadítsa benned a művészt, de korlátlan lehetőségeket kínál kreatív ötletei életre keltésére. Fogadja el a folyamatot, kutass tovább, és élvezze az örömet, hogy valami szépet alkothat. A textilnyomtatási utazása még csak most kezdődött, és az élénk színek világa, textúrák, és minták várnak rád.