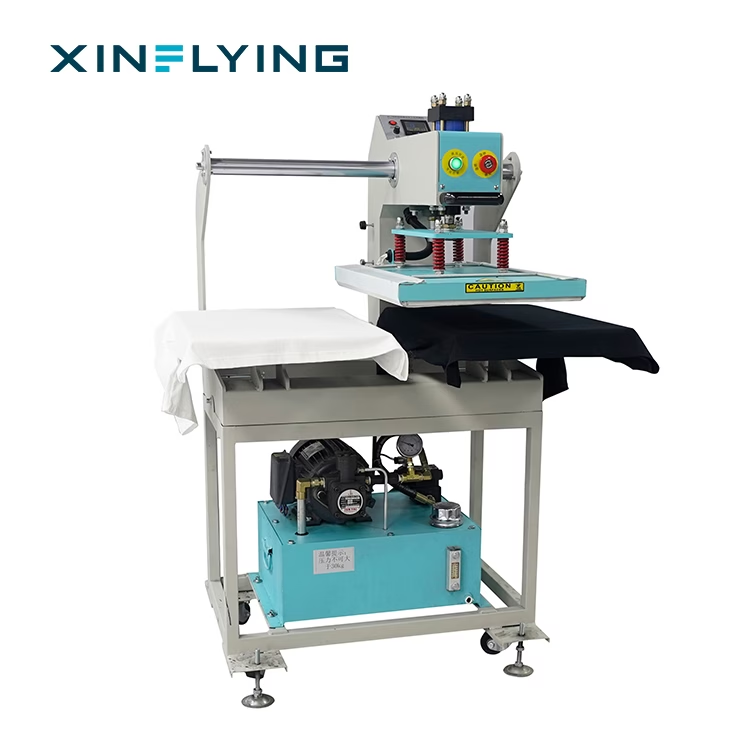

6040(7SER) Máquina de transferência de calor hidráulica de estação dupla semiautomática

Destaques do produto:

1.Projeto Hidráulico de Estação Dupla

Permite carregar e prensar simultaneamente para melhorar a eficiência da produção.

2.Pressão Uniforme & Controle de calor

O sistema hidráulico garante pressão consistente e resultados de transferência estáveis.

3.Confiável para operação contínua

Construído para longas horas de trabalho na produção de vestuário e têxteis.

4.Aplicações versáteis de transferência de calor

Adequado para roupas, tecidos, e vários materiais de transferência de calor.

Recursos profissionais

Especificações do produto

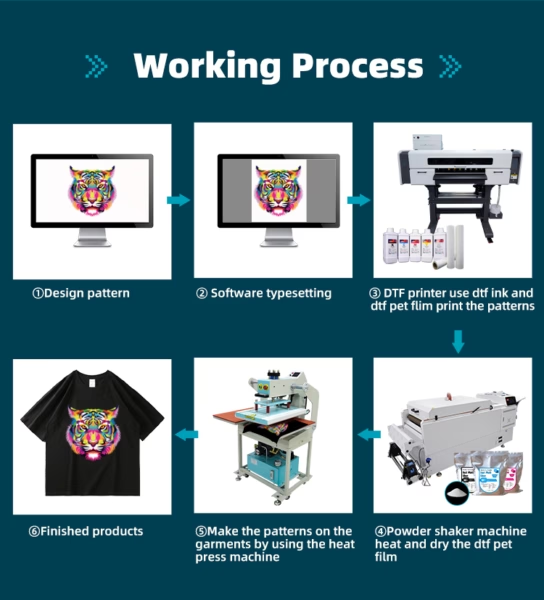

Processo de impressão

Aplicativo

Perguntas frequentes

Plataforma de trabalho de nível industrial equipada com uma tampa protetora superior. O design aumenta a segurança do operador, mantendo fácil acesso à área de prensagem, adequado para uso profissional contínuo.

Estrutura robusta do chassi principal combinada com uma caixa de controle integrada. Fornece suporte mecânico sólido enquanto aloja os principais componentes elétricos, garantindo uma operação segura, durabilidade, e fácil acesso para manutenção.

Sistema de ajuste de pressão de precisão integrado aos componentes de controle e estrutura de suporte. Permite regulação precisa da força de pressão e estabilidade operacional, melhorando a consistência e reduzindo a fadiga do operador.

Unidade completa de prensa térmica com placa de aquecimento superior reforçada e mesa de trabalho inferior estável. Projetado para distribuição uniforme de pressão e transferência de calor consistente, garantindo resultados confiáveis em produção de longa duração.

| Modelo | 6040(7SER) |

|---|---|

| Tamanho de impressão | 60x40 |

| Tensão (V) | 220V 1 fase/220V 3 fase/380v 3 fase |

| Limite de tempo | 0-999S |

| Poder(KW) | 4.3KW |

| Faixa de temperatura( °C) | 0-399 °C |

| Tamanho da máquina | 100*82*140CM |

| Tamanho do pacote | 195* 85*140CM |

| Peso líquido | 209.5KG |

| Peso bruto | 280KG |

Crie a arte usando software de design profissional.

Ajuste o layout e as cores no software RIP.

Imprima o desenho para transferir.

Use uma prensa térmica para transferir a imagem para tecido de poliéster (190–210ºC, 30-60 anos).

Brilhante, durável, e resultados duradouros.

1º trimestre: Como faço para usar uma máquina de prensa térmica?

A: Para usar uma máquina de prensa térmica, basta definir a temperatura, pressão, e tempo com base no material em que você está imprimindo. Coloque o item (Por exemplo, camiseta) na prensa térmica, posicione seu design, feche a imprensa, e aplique calor e pressão. Aguarde o cronômetro terminar, então remova seu item.

2º trimestre: Posso usar uma máquina de prensa térmica para todos os tecidos?

A: Sim, máquinas de prensa térmica podem ser usadas na maioria dos tecidos, incluindo algodão, poliéster, e misturas. No entanto, tecidos diferentes podem exigir configurações de temperatura e tempo diferentes, por isso verifique sempre a tolerância ao calor do tecido.

3º trimestre: Qual é a diferença entre prensas térmicas hidráulicas e manuais?

A: As prensas térmicas hidráulicas usam pressão hidráulica para distribuição uniforme, oferecendo resultados mais consistentes e maior eficiência, especialmente na produção de alto volume. Máquinas manuais requerem força física para aplicar pressão, o que pode não ser tão consistente ou eficiente para lotes maiores.

4º trimestre: Posso usar uma prensa térmica para chapéus?

A: Sim, especializado máquinas de prensa térmica para chapéus estão disponíveis para impressão em chapéus, cápsulas, e outros chapéus. Essas máquinas são projetadas para lidar com o formato e a curvatura exclusivos dos chapéus.

Largura de Impressão

Produtividade

cabeça de impressão

Dimensão

Largura de Impressão

Produtividade

cabeça de impressão

Dimensão

Largura de Impressão

Produtividade

cabeça de impressão

Dimensão

Saiba mais sobre nosso DTF, DTG, impressoras de sublimação, e consumíveis.

Saiba mais sobre nosso DTF, DTG, impressoras de sublimação e consumíveis.