White Ink Digital Transfer (DTF) tryckeri har funnits i bara cirka två decennier, vilket gör det till en relativt ny teknik. Trots sin ungdom, det har avsevärt påverkat hela branschen. Den utbredda användningen och tillgängligheten av DTF-teknik har drivit marknadstillväxten i en hisnande takt. Ännu, denna snabba tillväxt har också intensifierat konkurrensen inom branschen.

Utvecklingen av DTF-marknaden

Enligt en rapport från Keypoint Intelligence, DTF-utskriftsvolymen in 2022 uppskattades till ca 1.9 miljarder kvadratmeter. Av 2027, denna siffra förväntas skjuta i höjden till ungefär 10 miljarder kvadratmeter.

Sett till marknadsvärde, rapporten föreslår det detaljhandelsvärdet på DTF-marknaden var $2.78 miljarder in 2022. Av 2027, detta antal förväntas nå en svindlande $14 miljard. Rapporten belyser det “Antagandet av DTF är aldrig tidigare skådat i klädbranschen. I 2022, DTF-enheter stod för ca 44.5% av alla DTF, direkt till plagget (DTG), och överföringsenhetsinstallationer. Av 2027, DTF-skrivare förväntas göra upp 64.4% av sådana installationer.”

Rapporten noterar också det det fanns ungefär 9,082 DTF-enheter över hela världen i 2022. Detta antal förväntas växa till nästan 15,000 av 2027, med dubbla huvuden DTF-skrivare dominerar marknaden, och fyra-head DTF-skrivare utgör cirka en fjärdedel av marknadsandelen.

Kan DTF fortfarande vara ett lönsamt företag?

Med tanke på dessa trender, kan man undra: Kan DTF fortfarande vara en lönsam verksamhet? Det korta och definitiva svaret är: Ja. Dock, för leverantörer av utskriftstjänster (PSP:er) för att uppnå långsiktig lönsamhet och höga marginaler, de måste på ett skickligt sätt utnyttja DTF-trycktekniken i tjänsteerbjudanden och produktion.

De senaste åren, tillgängligheten för DTF-maskiner har drivit marknadstillväxten. Prisvärda utrustningslösningar från Kina innebär att nästan alla kan erbjuda DTF-tjänster till kunder. Även om detta är bra för företag som vill diversifiera sig, det har också lett till att marknaden är mättad.

Keypoint Intelligences rapport tar direkt upp denna fråga, noterar det “DTF-marknaden är fortfarande i ett tidigt skede, med betydande oro bland hårdvaruleverantörer. Dess utvecklingsväg speglar den tidiga utvecklingen av DTG.”

Så, hur kan man sticka ut från konkurrenterna och attrahera värdefulla kunder? Svaret är enkelt: erbjuda bättre service.

För kunder som söker snabba och billiga lösningar utan höga kvalitetskrav, det finns många alternativ. Dock, Kvalitetsmedvetna kunder föredrar att arbeta med en utmärkt DTF-skrivartillverkare, vilket innebär att samarbeta med DTF-skrivarmaskin av högsta klass.

Varför är DTF så populär?

Innan du dyker in i vad som gör en högkvalitativ DTF-maskin, låt oss först förstå DTF och varför denna teknik är så populär inom textiltryckstekniker.

Lätt att lära sig och bemästra

För det första, DTF-teknik är lätt att lära sig och bemästra. Utskrift med vattenbaserat pigmentbläck på PET-film är ganska likt pappersutskrift, vilket gör det enkelt för tryckerier. Dessutom, det kan göras på ett relativt litet utrymme, gör det tillgängligt för företag av alla storlekar.

Snabb utskriftshastighet

För det andra, DTF-utskriftstekniken är snabb, gör det möjligt för PSP:er att uppnå snabba handläggningstider. När filmutskriften är klar, den kan lagras tills den behövs för överföring, gör det möjligt för PSP:er att förbereda arbetet i förväg och eliminera behovet av dubbelvit eller CMYK-utskrift med andra metoder.

Den mest kostnadseffektiva processen

Dessutom, medan DTF -film och varmt limpulver medföra ytterligare kostnader, DTF visar sig ofta vara den mest kostnadseffektiva processen, ger ekonomiska fördelar för PSP:er av olika storlek.

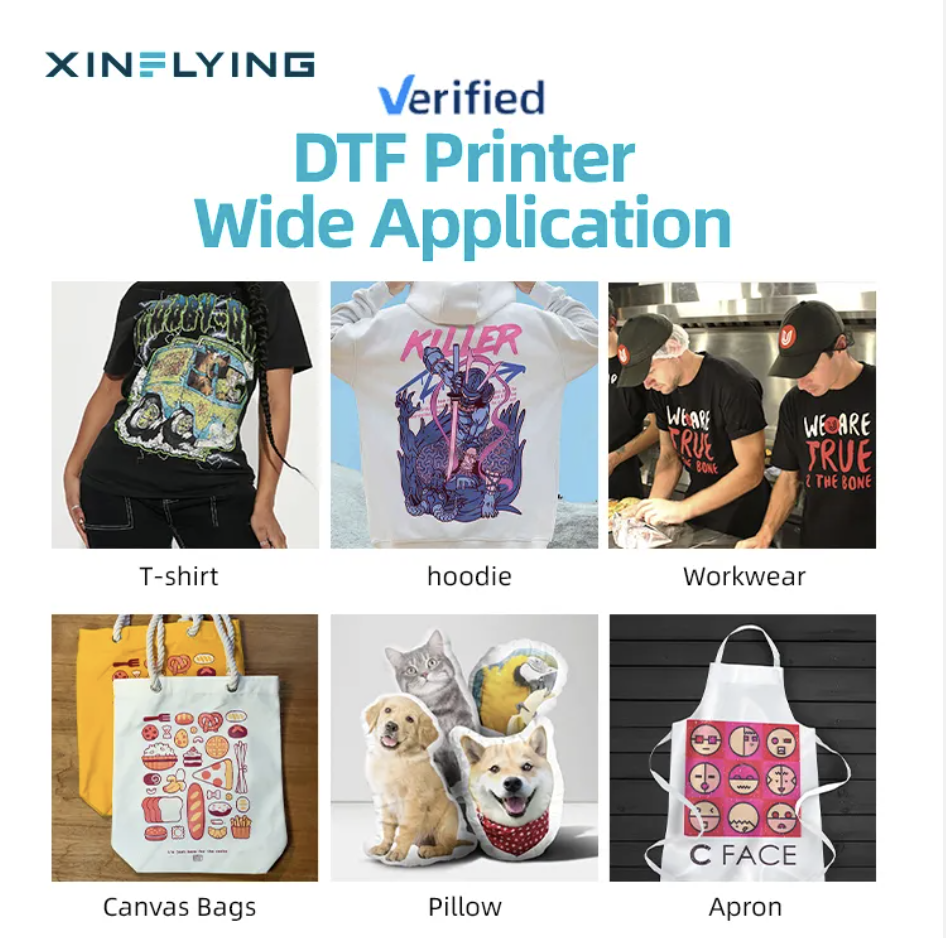

Brett tillämpningsområde

Slutligen, det breda applikationsutbudet öppnar upp olika marknader för tryckeriföretag. DTF-utskriftsteknik kan användas för utskrift på vanliga kläder som t-shirts, hoodies, och sportkläder, samt reklamartiklar och till och med inredning.

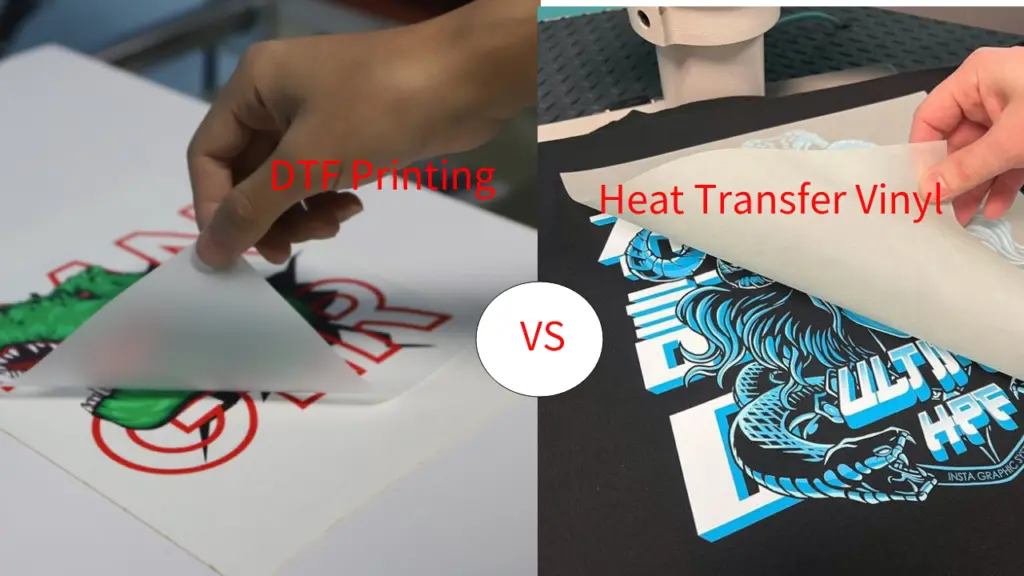

DTF vs. DTG -tryckning

När man diskuterar DTF, måste vi också nämna DTG. När allt kommer omkring, båda använder direkta utskriftsmetoder.

DTG-utskrift kräver inte överföringar eller film och pulver, men även med dessa kostnader beaktade, DTF erbjuder fortfarande ofta en kostnadsfördel. Dessutom, DTF behöver ingen förbehandling och är lämplig för olika fibertyper. Slutligen, när det gäller färgomfång, fina detaljer, och plaggets elasticitet, DTF-utskriftsmetoden har unika fördelar.

Framtiden för DTF-utskriftsteknik

Punkterna som diskuterats ovan är baserade på aktuella marknadserbjudanden, men hur är det med framtiden?

Innovationer kl 2024 FESPA

Vid 2024 FESPA, vi såg några innovationer inom DTF-området, med tillverkare och leverantörer som lovar många spännande utvecklingar. En av nyckelfaktorerna som påverkar DTF-marknaden och alla tryckeribranschen är hållbarhet. I takt med att kundernas efterfrågan på miljövänligt tryck växer, tillverkarna måste svara, vilket är uppenbart i DTF-domänen.

Mimakis senaste erbjudanden

Ta Mimaki, till exempel. Tillverkaren tillkännagav nyligen den nya Mimaki TxF300-75, kan trycka på bomull, polyester, och polyesterblandningar, samt ljusa och mörka tyger, erbjuder det bästa av både DTF- och DTG-utskriftsvärlden.

Den nya maskinen kommer med två års standardgaranti och använder Mimaki-bläck certifierade av OEKO-TEX ECO PASSPORT, möta den ökande kundefterfrågan på hudvänlig och miljövänlig produktion.

Den här nya modellen syftar till att bygga vidare på den tidiga framgången för Mimakis DTF-serie som lanserades förra året. TxF150-75 har sålt över 300 enheter i Europa, Mellanöstern, och Afrika. Mimaki hävdar att den senaste modellen är tre gånger snabbare än tidigare modeller, designad för den professionella marknaden för bulkdekoration av plagg.

“Hybrid försäljningsdirektör säger, "TxF300-75 visar den snabba ökningen i popularitet för direkt-till-film-processer. Nu, lanseras tillsammans med den framgångsrika TxF150-75, det erbjuder fler valmöjligheter för företag som går in på eller expanderar på marknaden för plaggdekoration.'”

RA Smart stöder även DTF, ha distribuerat DTF-lösningar från Polytech, en av pionjärerna inom DTF-teknik, sedan 2021.

RA Smarts bidrag

RA Smarts produktmarknadschef Alex Mighall har varit med om denna marknadsexpansion. Han tillskriver den anmärkningsvärda tillväxten av DTF till dess unika tekniska fördelar och lyfter fram framväxten av många olika DTF-plattformar under de senaste åren. Han tillägger att tillströmningen av stora varumärken bara kommer att driva ytterligare tillväxt.

“Utan tvivel, DTF-teknik erbjuder en utmärkt lösning, men att arbeta med välrenommerade distributörer är avgörande för att minimera inlärningskurvan för ny teknik så mycket som möjligt.”

Marknadstrender och framtidsutsikter

Angående marknadstrender, RA Smart har identifierat en övergripande trend inom DTF-maskiner: ger snabbare handläggningstider för kunder och ökar mångfalden av produkter som en enskild maskin kan producera.

Han konstaterar att stora tryckleverantörer nu investerar i flera maskiner och effektivare system, så efterfrågan på system med högre produktivitet kommer att fortsätta att växa.

Ska du investera i en DTF-skrivare?

Det finns utan tvekan många alternativ för DTF -skrivarmaskin, men åsikterna om huruvida man ska investera kommer att variera. För dig som vill komma in på DTF-marknaden, ett alternativ är att samarbeta med professionell tillverkare av textilskrivare. Naturligtvis, detta innebär att ge upp lite vinst men också slippa besväret med att investera i utbildning och att kunna börja ta emot beställningar direkt.

Så, är det värt det? Det beror på hur mycket DTF du planerar att göra. Om du redan har avtal med befintliga kunder, är säkra på dina beställningar, och är skickliga i denna teknik, det kan vara värt att dyka in direkt. Å andra sidan, om du funderar på att testa vattnet innan du fullföljer det, partnerskap med en handelspartner är också ett bra alternativ.

Slutsats

Avslutningsvis, det finns mycket att vara exalterad över när det kommer till DTF-utskriftsteknik. Denna teknik möjliggör inte bara produktion av olika tryckta produkter utan visar också en snabb utveckling, med många stora företag som kommer in på marknaden med sina egna DTF-maskiner. Detta tyder på att vi kan förvänta oss ännu mer tillväxt och expansion på denna redan mycket aktiva marknad.