Bevezetés

Rugalmasságának köszönhetően a DTF-nyomtatás az egyedi ruházati ipar általános megoldásává vált, élénk színek, és kompatibilitás több szövettel. azonban, tökéletes elérése DTF átvitel nem csak a birtoklásától függ DTF nyomtató.

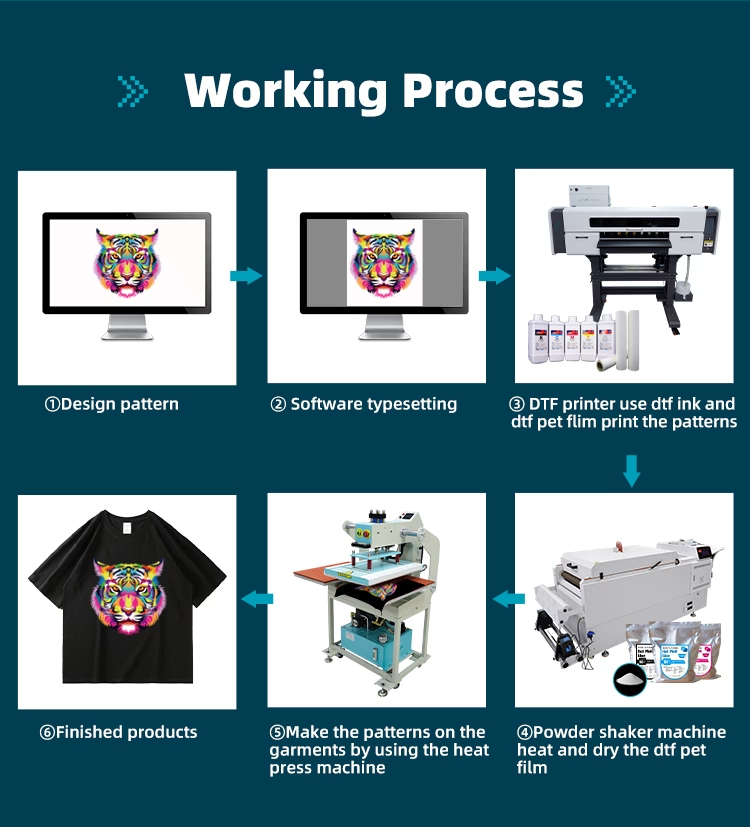

Mivel a DTF nyomtatás több lépésből áll – a nyomtatás, por alkalmazás, gyógyító, és hőpréselés – még egy kisebb hiba is gyenge tapadáshoz vezethet. Az egyik leggyakoribb probléma, amellyel a felhasználók találkoznak A DTF átvitelek nem tapadnak megfelelően.

Ez az útmutató elmagyarázza a a DTF átviteli hiba fő okai és praktikus megoldásokat kínál a nyomtatás tartósságának és konzisztenciájának javítására.

Gyakori okok, amelyek miatt a DTF-átvitelek nem tapadnak meg

A fűtőprés hőmérséklete vagy nyomása nem megfelelő

A hőpréselés a DTF átviteli folyamat utolsó és legkritikusabb szakasza.

Ha a hőmérséklet túl alacsony, a ragasztópor nem tud teljesen megolvadni, gyenge kötést eredményez. Hasonlóképpen, az elégtelen nyomás megakadályozza, hogy a tinta és a ragasztó behatoljon a szövetszálakba.

A gyakori problémák közé tartozik:

- Alacsony hőmérséklet → a ragasztó nem teljes aktiválása

- Nem megfelelő nyomás → felületi tapadás

- Egyenetlen nyomás → részleges hámlás

A környezeti feltételek befolyásolják a DTF átvitel minőségét

A környezeti tényezők jelentős szerepet játszanak a DTF-nyomtatás sikerében.

- A magas páratartalom a ragasztópor összetapadását okozhatja

- A rossz szellőzés nem teljes porszáradáshoz vezethet

- A por és a törmelék szennyezheti a transzfer felületet

A tisztaság fenntartása, száraz, és a jól szellőző munkaterület elengedhetetlen a stabil DTF átviteli eredményekhez.

Nem megfelelő mennyiségű DTF ragasztópor

A por alul- és túlzott felhordása egyaránt tapadási problémákat okozhat.

- A túl kevés por gyenge vagy hiányzó tapadási területekhez vezet

- A túl sok por sűrűséget hoz létre, merev transzferek, amelyek megrepedhetnek

A cél az még, teljes lefedettség túlzott felhalmozódás nélkül.

Gyenge minőségű vagy sérült DTF transzferfólia

Nem minden DTF transzferfólia nyújt egyenletes teljesítményt.

Az alacsony minőségű filmek gyakran szenvednek:

- Egyenetlen bevonat

- Gyenge ragasztórétegek

- Rossz kioldási tulajdonságok

Még a prémium filmek is meghibásodhatnak, ha megkarcolódnak, összehajtogatva, vagy helytelenül tárolták.

Lásd az összehasonlító útmutatót:Hot Peel vs Cold Peel DTF filmek magyarázata

A film túl korai lehúzása

A DTF átvitelek megfelelő hűtési időt igényelnek a hámozás előtt.

Lehetséges, hogy túl korán lehúzzuk a filmet:

- Emelje ki a tintát az anyagból

- Torzítsa el a tervezést

- Csökkentse a hosszú távú tartósságot

Mindig kövesse a fólia gyártójának leválasztási utasításait.

A DTF átvitel tapadásával kapcsolatos problémák megoldása

Használjon kiváló minőségű DTF tintát és port

Az alacsony költségű fogyóeszközök gyakran inkonzisztens tapadást és gyenge mosásállóságot eredményeznek.

A legjobb gyakorlatok:

- A tömeges gyártás előtt tesztelje a tintákat és a porokat

- Kerülje a lejárt vagy nem megfelelően tárolt anyagokat

- Vásároljon megbízhatótól DTF nyomtató beszállítók

Fedezd fel: DTF fogyóeszközök útmutatója: Tinta, Por, Film magyarázata

Illessze a megfelelő szövetet DTF rendszeréhez

Bár a DTF nyomtatás sok textílián működik, nem minden szövet viselkedik egyformán.

Pamut, poliészter, és a keverékek általában jól teljesítenek, de a különböző porok és tinták eltérően reagálhatnak.

Mindig tesztelje az új szöveteket, mielőtt nagy gyártási sorozatokat végezne.

Optimalizálja DTF-nyomtatási munkafolyamatát

A stabil munkafolyamat javítja a konzisztenciát és csökkenti a hulladék mennyiségét.

Az optimalizálás legfontosabb lépései:

- Kalibrálja a DTF nyomtatót a megfelelő tintasűrűség érdekében

- Állítsa be a hőprés hőmérsékletét és nyomását szövettípusonként

- Teljesen kikeményedő ragasztópor

- Kövesse a megfelelő hűtési és hámozási eljárásokat

Gyakran ismételt kérdések a DTF-átvitelekkel kapcsolatban

K: Milyen hőmérsékletet használjak a DTF átvitelhez??

A legtöbb DTF átvitel megköveteli 300–350°F (150-177 °C) -ra 15-20 másodperc, az anyagtól és a por típusától függően.

K: Használhatok normál nyomtatót DTF átvitelhez??

Nem. A DTF átvitelhez dedikált vagy konvertált szükséges DTF nyomtató DTF tintával és filmmel kompatibilis.

K:Miért hámlik le a DTF-em a mosás után??

A hámlást általában az okozza:

- Nem megfelelő kikeményedés

- Helytelen hőprésbeállítások

- Gyenge minőségű vagy lejárt fogyóeszközök

- Összeférhetetlen szövet

K: Megrepedhet-e a DTF átvitel az idő múlásával?

Repedés előfordulhat, ha:

- Túl sok port alkalmazunk

- A nyomás túl magas vagy túl alacsony

- Alacsony minőségű anyagokat használnak

A megfelelő beállítások és minőségi fogyóeszközök használata segít megelőzni a repedéseket.

K:Mennyibe kerül egy DTF nyomtató?

A DTF nyomtató ára változó:

- Belépő szintű vagy átalakított modellek: $500– 1000 dollár

- Professzionális DTF nyomtatók: $1,000– 15 000+ dollár, mérettől és konfigurációtól függően

Következtetés

Amikor a A DTF átvitel nem ragad, az ok általában a beállításokkal kapcsolatos, fogyóeszközök, környezet, vagy folyamatirányítás – nem maga a technológia.

A saját optimalizálásával DTF nyomtató beállítása, megbízható anyagok felhasználásával, és a legjobb gyakorlatok követése, következetesen termelhet tartós, vibráló, és mosásálló DTF transzferek.