เครื่องพิมพ์ DTF กำลังปฏิวัติอุตสาหกรรมการพิมพ์. พวกเขาเสนอวิธีใหม่ในการถ่ายโอนการออกแบบลงบนสิ่งทอ เทคโนโลยีนี้เรียกว่าการพิมพ์โดยตรงไปยังฟิล์ม. ให้ความมีชีวิตชีวา, ทนทานต่อการพิมพ์บนเนื้อผ้าต่างๆ ไม่เหมือนวิธีการแบบเดิมๆ, การพิมพ์ DTF มีประสิทธิภาพและหลากหลาย. ไม่จำเป็นต้องมีหน้าจอหรือการตั้งค่าที่กว้างขวาง กระบวนการนี้เกี่ยวข้องกับการพิมพ์การออกแบบลงบนฟิล์มพิเศษ. แล้ว, ทาผงกาวก่อนรีดความร้อนลงบนผ้า. เครื่องพิมพ์ DTF เหมาะสำหรับการผลิตทั้งขนาดเล็กและขนาดใหญ่. ทำให้เหมาะสำหรับความต้องการทางธุรกิจที่แตกต่างกัน เทคโนโลยีนี้กำลังได้รับความนิยมในเครื่องแต่งกายสั่งทำพิเศษ. ให้งานพิมพ์คุณภาพสูงพร้อมความมีชีวิตชีวาของสีที่ยอดเยี่ยม.

ในคู่มือนี้, เราจะมาสำรวจเครื่องพิมพ์ DTF โดยละเอียด. คุณจะได้เรียนรู้เกี่ยวกับผลประโยชน์ของพวกเขา, การใช้งาน, และวิธีการทำงาน. เครื่องพิมพ์ DTF พิมพ์ลวดลายสีสันสดใสบนผ้าฝ้ายและผ้าโพลีเอสเตอร์.

เครื่องพิมพ์ DTF คืออะไร?

เครื่องพิมพ์ DTF คือเครื่องพิมพ์ประเภทหนึ่งที่ใช้สำหรับการพิมพ์แบบ Direct to Film. เทคโนโลยีนี้ช่วยให้สามารถพิมพ์การออกแบบลงบนฟิล์มพิเศษแล้วถ่ายโอนไปยังสิ่งทอได้. เป็นวิธีการพิมพ์สมัยใหม่ที่เชื่อมโยงประสิทธิภาพเข้ากับคุณภาพ.

แกนหลักของเทคโนโลยี DTF อยู่ที่ความสามารถในการผลิตที่มีรายละเอียด, ลายพิมพ์ที่มีชีวิตชีวา. ใช้การผสมผสานระหว่างหมึกและฟิล์มพิเศษ. เทคโนโลยีนี้ให้ภาพที่มีความละเอียดสูงพร้อมความลึกของสีที่น่าประทับใจบนผ้าชนิดต่างๆ.

เครื่องพิมพ์ DTF ค่อนข้างแตกต่างจากเครื่องพิมพ์สิ่งทอทั่วไป. ไม่จำเป็นต้องมีการจัดเตรียมหรือคัดกรองมากนัก. การขาดการตั้งค่านี้ทำให้เหมาะสำหรับการดำเนินการอย่างรวดเร็วและคำสั่งซื้อที่กำหนดเอง.

ส่วนประกอบสำคัญของเครื่องพิมพ์ DTF ได้แก่:

1.ตัวเครื่องพิมพ์พร้อมเทคโนโลยีการพิมพ์ขั้นสูง

2.หมึก DTF พิเศษเพื่อสีสันสดใส

3.ฟิล์มถ่ายโอนที่พิมพ์ภาพตั้งแต่แรก

4.เครื่องรีดความร้อนเพื่อถ่ายโอนแบบไปยังผ้า

เทคโนโลยีนี้สามารถนำไปปรับใช้กับเนื้อผ้าหลายชนิด เช่น ผ้าฝ้ายและโพลีเอสเตอร์. เครื่องพิมพ์ DTF มีความหลากหลาย, รองรับความซับซ้อนในการออกแบบและโทนสีต่างๆ. พวกเขาเปิดโอกาสใหม่ๆ ให้กับธุรกิจในด้านเสื้อผ้าสั่งทำและผลิตภัณฑ์ส่งเสริมการขาย.

การพิมพ์ DTF ทำงานอย่างไร: กระบวนการทีละขั้นตอน

การพิมพ์ DTF เป็นกระบวนการที่เป็นนวัตกรรมใหม่ที่เปลี่ยนการออกแบบดิจิทัลให้เป็นงานศิลปะที่สวมใส่ได้. เริ่มต้นด้วยการสร้างงานศิลปะโดยใช้ซอฟต์แวร์ออกแบบ, ซึ่งจะถูกจัดเตรียมเพื่อส่งออกไปยังเครื่องพิมพ์ DTF เฉพาะทาง.

ขั้นตอนแรกคือการพิมพ์ภาพลงบนฟิล์ม DTF ที่เคลือบเป็นพิเศษ. หนังเรื่องนี้เก็บทุกรายละเอียด, ในขณะที่ชั้นหมึกสีขาวมักจะพิมพ์ไว้ใต้ชั้นสีเพื่อเพิ่มความมีชีวิตชีวาและรับประกันว่าการออกแบบจะโดดเด่นบนผ้าทุกสี.

หลังจากการพิมพ์, ใช้ผงกาวละเอียดกับหมึกเปียกบนฟิล์ม. ผงนี้ทำหน้าที่เป็นสารยึดเกาะ, ทำให้การออกแบบสามารถยึดติดกับเนื้อผ้าได้อย่างแน่นหนาในระหว่างขั้นตอนการถ่ายโอน.

ต่อไป, ภาพยนตร์เรื่องนี้หายแล้ว. โดยใช้การควบคุมความร้อน, กาวจะยึดติดกับหมึก, เตรียมการโอนการสมัคร. ขั้นตอนการบ่มนี้มักจะดำเนินการโดยใช้เครื่องรีดความร้อนหรือเตาอบสำหรับบ่ม.

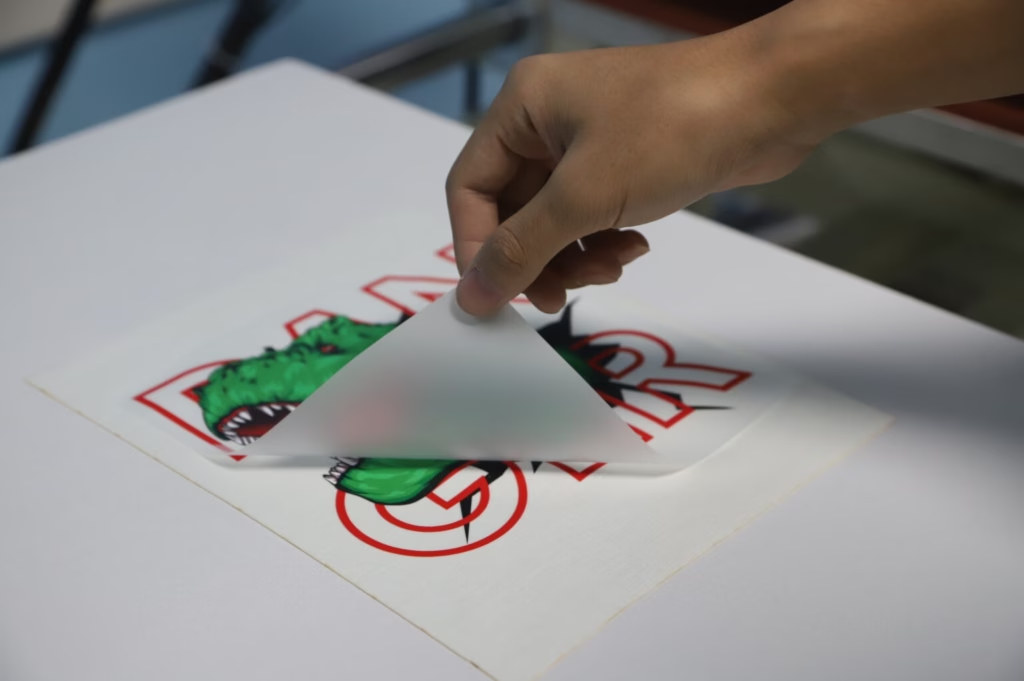

ขั้นตอนสุดท้ายคือการถ่ายโอนการออกแบบลงบนผ้า. โดยการกดฟิล์มลงบนเสื้อผ้าด้วยการกดความร้อน, ความร้อนและความดันจะหลอมรวมภาพเข้ากับวัสดุได้อย่างลงตัว, ส่งผลให้งานพิมพ์มีความคงทนและมีชีวิตชีวา.

ขั้นตอนสำคัญในกระบวนการพิมพ์ DTF ได้แก่:

- การสร้างการออกแบบในซอฟต์แวร์กราฟิก

- พิมพ์การออกแบบบนฟิล์ม DTF

- การทาและบ่มผงกาว

- ความร้อนกดลวดลายลงบนผ้า

กระบวนการนี้ทำให้ได้งานพิมพ์คุณภาพสูงพร้อมสีสันสดใสและรายละเอียดที่คมชัด. การพิมพ์ DTF ไม่เพียงแต่มีประสิทธิภาพและอเนกประสงค์เท่านั้น แต่ยังได้รับการยกย่องอย่างสูงในเรื่องความทนทานและผลลัพธ์ภาพที่น่าประทับใจอีกด้วย.

การโอน DTF: วัสดุและอุปกรณ์ที่จำเป็น

เพื่อดำเนินการถ่ายโอน DTF อย่างมีประสิทธิภาพ, วัสดุและอุปกรณ์ที่เหมาะสมถือเป็นสิ่งสำคัญ. ส่วนประกอบหลักคือเครื่องพิมพ์ DTF, ซึ่งออกแบบมาโดยเฉพาะสำหรับกระบวนการพิมพ์นี้. เครื่องพิมพ์ DTF คุณภาพสูงช่วยให้มั่นใจได้ถึงความแม่นยำ, ให้ภาพที่สดใสบนแผ่นฟิล์ม.

ฟิล์ม DTF ก็มีบทบาทสำคัญไม่แพ้กัน. ฟิล์มเคลือบพิเศษนี้คงลวดลายที่พิมพ์ไว้ก่อนที่จะถ่ายโอนไปยังผ้า และได้รับการออกแบบให้ทนต่ออุณหภูมิสูงโดยไม่บิดเบี้ยวในระหว่างกระบวนการถ่ายโอน.

หมึก DTF โดยทั่วไปคือ CMYK บวกกับสีขาว ได้รับการออกแบบมาเพื่อมอบความมีชีวิตชีวา, งานพิมพ์ที่ยาวนาน. โดยจะยึดติดกับฟิล์มและติดกับเนื้อผ้าในภายหลังโดยการกระตุ้นความร้อนและการติดด้วยกาว.

จากนั้นจึงนำผงกาวไปใช้กับฟิล์มที่พิมพ์. ผงนี้ช่วยให้หมึกติดแน่นกับเนื้อผ้าในระหว่างการกด, ทำให้งานพิมพ์มีความทนทานแม้ผ่านการซักซ้ำหลายครั้ง.

ในที่สุด, ต้องใช้เครื่องกดความร้อนเพื่อให้การถ่ายโอนเสร็จสมบูรณ์. ให้ความร้อนและแรงกดที่จำเป็นในการเคลื่อนย้ายดีไซน์จากฟิล์มไปยังผ้า, สร้างผลลัพธ์ที่เรียบเนียนและติดทนนาน.

วัสดุและอุปกรณ์สำคัญได้แก่:

- เครื่องพิมพ์ดีทีเอฟ

- ฟิล์มดีทีเอฟ

- หมึก DTF(CMYK และสีขาว)

- ผงกาว

- กดความร้อน

ประโยชน์หลักของการพิมพ์ DTF

การพิมพ์ DTF มีข้อดีหลายประการซึ่งทำให้เป็นตัวเลือกที่น่าดึงดูดสำหรับธุรกิจจำนวนมาก.

ประโยชน์หลักประการหนึ่งคือความอเนกประสงค์. เครื่องพิมพ์ DTF สามารถพิมพ์บนผ้าได้หลากหลายประเภท, ตั้งแต่ผ้าฝ้ายไปจนถึงโพลีเอสเตอร์และผ้าผสม.

กระบวนการพิมพ์รองรับการออกแบบที่ซับซ้อนและมีความแม่นยำของสีสูง. เครื่องพิมพ์ DTF สามารถผลิตชิ้นงานที่คมชัดได้, ภาพที่สดใสด้วยขอบเขตสีที่กว้าง.

ทำให้เหมาะสำหรับกราฟิกและโลโก้ที่ซับซ้อน.

ข้อดีอีกประการหนึ่งคือความทนทานของงานพิมพ์. งานพิมพ์ DTF ทนทานต่อการซีดจางและการแตกร้าว.

คงรูปลักษณ์ไว้แม้ผ่านการซักหลายครั้ง, นำเสนอคุณภาพที่ยาวนาน.

กระบวนการนี้ยังคุ้มค่าอีกด้วย, โดยเฉพาะสำหรับการวิ่งระยะสั้น. ต่างจากการพิมพ์สกรีน, DTF ไม่ต้องการการตั้งค่าที่กว้างขวาง. ซึ่งช่วยลดทั้งต้นทุนและของเสีย, ทำให้เหมาะสำหรับคำสั่งซื้อที่กำหนดเองและชุดเล็กๆ.

การพิมพ์ DTF ยังใช้งานง่ายอีกด้วย. เครื่องพิมพ์ DTF สมัยใหม่มาพร้อมกับอินเทอร์เฟซที่ใช้งานง่ายและต้องการการบำรุงรักษาเพียงเล็กน้อย, ทำให้สามารถเข้าถึงได้ทั้งผู้เริ่มต้นและมืออาชีพที่มีประสบการณ์.

ในที่สุด, เทคโนโลยี DTF ช่วยให้ดำเนินการได้รวดเร็ว. ขั้นตอนการทำงานที่คล่องตัวและความสามารถในการหลีกเลี่ยงการตั้งค่าที่มีความยาว ทำให้เหมาะสำหรับบริการการพิมพ์ตามต้องการ.

ประโยชน์ที่สำคัญได้แก่:

- หมุนอย่างรวดเร็วไปยังเสื้อผ้าใดๆ ภายในไม่กี่วินาที.

- ความหลากหลายในประเภทผ้า

- ความแม่นยำและรายละเอียดของสีสูง

- ทนทาน, งานพิมพ์ที่ยาวนาน

- ความคุ้มค่าในระยะสั้น

- การดำเนินงานที่เป็นมิตรต่อผู้ใช้

การพิมพ์ DTF เทียบกับวิธีการพิมพ์อื่นๆ

เมื่อเปรียบเทียบการพิมพ์ DTF กับเทคนิคอื่นๆ, ปัจจัยหลายประการทำให้มันแตกต่าง. การพิมพ์สกรีนแบบดั้งเดิมเกี่ยวข้องกับการใช้ลายฉลุเพื่อสร้างการออกแบบ, ซึ่งอาจต้องใช้แรงงานเข้มข้นและมีค่าใช้จ่ายสูงสำหรับการวิ่งขนาดเล็ก. การพิมพ์ DTF ช่วยให้กระบวนการง่ายขึ้นโดยไม่จำเป็นต้องใช้หน้าจอและสเตนซิล.

อีกวิธีหนึ่งที่พบบ่อยคือการสวมเสื้อผ้าโดยตรง (ดีทีจี) การพิมพ์, ซึ่งใช้หมึกลงบนผ้าโดยตรง. DTG เป็นเลิศในรายละเอียดแต่ยังต้องดิ้นรนกับเนื้อผ้าที่ซับซ้อน. ในทางตรงกันข้าม, DTF สามารถพิมพ์บนวัสดุได้หลากหลายโดยไม่กระทบต่อคุณภาพ.

การพิมพ์แบบระเหิดเป็นที่นิยมสำหรับโพลีเอสเตอร์, แต่ก็ไม่อเนกประสงค์กับผ้าชนิดอื่น. การพิมพ์ DTF, อย่างไรก็ตาม, จัดการกับสิ่งทอประเภทต่าง ๆ ได้อย่างมีประสิทธิภาพ. ความสามารถในการปรับตัวนี้ทำให้เป็นตัวเลือกที่ต้องการสำหรับเครื่องแต่งกายที่ออกแบบเอง.

ไวนิลการถ่ายเทความร้อน (เอชทีวี) ต้องมีการตัดและกำจัดวัชพืชก่อนที่จะกดลงบนผ้า. กระบวนการนี้อาจใช้เวลานานและจำกัดความซับซ้อนในการออกแบบ. การพิมพ์ DTF ข้ามข้อจำกัดเหล่านี้ด้วยขั้นตอนการทำงานที่คล่องตัว.

สรุป, การพิมพ์ DTF ผสมผสานความอเนกประสงค์เข้าด้วยกัน, ประสิทธิภาพ, และรายละเอียดที่ทำให้แตกต่างจากวิธีอื่นๆ.

- HTV จำกัดความซับซ้อนในการออกแบบ

- การพิมพ์สกรีนต้องใช้ลายฉลุ

- DTG ดิ้นรนกับผ้าที่หลากหลาย

- การระเหิดจำกัดอยู่ที่โพลีเอสเตอร์

การใช้งานเครื่องพิมพ์ DTF ในอุตสาหกรรม

เครื่องพิมพ์ DTF กำลังปฏิวัติภาคส่วนต่างๆ, ด้วยความเก่งกาจของพวกเขาเป็นข้อได้เปรียบที่สำคัญ. ในวงการแฟชั่น, มีการใช้กันอย่างแพร่หลายในการผลิตเครื่องแต่งกายตามสั่งและสินค้ารุ่นลิมิเต็ด. นักออกแบบให้ความสำคัญกับความสามารถในการทดลองใช้รูปแบบที่เป็นเอกลักษณ์และกราฟิกที่ซับซ้อน.

สินค้าส่งเสริมการขายยังได้รับประโยชน์จากเทคโนโลยี DTF. ธุรกิจสามารถนำเสนอสินค้าเฉพาะบุคคล เช่น กระเป๋าโท้ต, หมวก, และอุปกรณ์สั่งทำพิเศษเพื่อเพิ่มการมองเห็นแบรนด์. การปรับแต่งระดับนี้ดึงดูดทั้งธุรกิจขนาดเล็กและองค์กรขนาดใหญ่.

การพิมพ์ DTF ยังโดดเด่นในตลาดของขวัญด้วยการเปิดใช้งานตามความต้องการ, ผลิตภัณฑ์ส่วนบุคคล. ผู้บริโภคสามารถสร้างการออกแบบที่เป็นเอกลักษณ์ให้กับสินค้าได้หลากหลาย, ตั้งแต่เสื้อยืดไปจนถึงแก้วน้ำ. ความยืดหยุ่นนี้ช่วยให้ธุรกิจสามารถขยายการนำเสนอผลิตภัณฑ์ของตนได้โดยไม่ต้องมีภาระสินค้าคงคลังส่วนเกิน.

ยิ่งกว่าเสื้อผ้าอีกด้วย, เครื่องพิมพ์ DTF ใช้ในการพิมพ์บนอุปกรณ์เสริม, ตกแต่งบ้าน, และอื่น ๆ.

ความสามารถในการปรับตัวนี้ช่วยให้ธุรกิจต่างๆ สามารถลงทุนในกลุ่มเฉพาะต่างๆ มากมายด้วยความมั่นใจและความคิดสร้างสรรค์.

สินค้าส่งเสริมการขายของตกแต่งบ้านและของตกแต่งบ้าน, ก เครื่องพิมพ์ดีทีเอฟ สามารถเป็นผู้เปลี่ยนเกมได้.

- เครื่องแต่งกายและแฟชั่นที่กำหนดเอง

- รายการส่งเสริมการขายและของขวัญขององค์กร

- โซลูชั่นของขวัญส่วนบุคคล

การเลือกเครื่องพิมพ์ DTF ที่เหมาะกับความต้องการของคุณ

การเลือกเครื่องพิมพ์ DTF ในอุดมคติเกี่ยวข้องกับการพิจารณาปัจจัยสำคัญหลายประการเพื่อตอบสนองความต้องการทางธุรกิจของคุณ. อันดับแรก, ประเมินขนาดการดำเนินงานของคุณ. ธุรกิจขนาดเล็กอาจได้รับประโยชน์จากโมเดลขนาดกะทัดรัด, ในขณะที่องค์กรขนาดใหญ่อาจต้องการเครื่องจักรที่มีความจุสูง.

ต่อไป, ประเมินว่าเครื่องพิมพ์ทำงานร่วมกับขั้นตอนการทำงานปัจจุบันของคุณได้ดีเพียงใด. เลือกคุณสมบัติที่ทำงานได้อย่างราบรื่นกับซอฟต์แวร์และระบบที่มีอยู่ของคุณ. อินเทอร์เฟซที่ใช้งานง่ายช่วยให้ทีมของคุณเปลี่ยนผ่านได้ง่ายขึ้น.

งบประมาณเป็นอีกหนึ่งปัจจัยสำคัญ. ในขณะที่ค่าใช้จ่ายล่วงหน้าจะแตกต่างกันไป, ตรวจสอบให้แน่ใจว่าความสามารถของเครื่องพิมพ์นั้นสมเหตุสมผลในการลงทุน. พิจารณาการประหยัดในระยะยาวและผลตอบแทนที่อาจเกิดขึ้นจากการผลิตงานพิมพ์คุณภาพสูง.

ในที่สุด, ลองนึกถึงประเภทวัสดุที่คุณวางแผนจะพิมพ์. เลือกเครื่องพิมพ์ที่รองรับวัสดุพิมพ์ต่างๆ, เช่นผ้าฝ้าย, โพลีเอสเตอร์, และผสมผสาน. ความหลากหลายของวัสดุที่มากขึ้นช่วยขยายการนำเสนอผลิตภัณฑ์และโอกาสทางการตลาดของคุณ.

สุดท้ายนี้, ประเมินตัวเลือกการสนับสนุนและการรับประกันที่ได้รับจากผู้ผลิต.

ระบบสนับสนุนที่เชื่อถือได้รับประกันการทำงานที่ราบรื่นยิ่งขึ้นและการแก้ไขปัญหาที่รวดเร็ว.

- ขนาดของการดำเนินงาน

- ความเข้ากันได้ของเวิร์กโฟลว์

- การพิจารณางบประมาณ

- ความเข้ากันได้ของวัสดุ

- การสนับสนุนและการรับประกัน

เคล็ดลับเพื่อความสำเร็จในการพิมพ์ DTF

การได้รับผลลัพธ์สูงสุดด้วยการพิมพ์ DTF จำเป็นต้องมีการเตรียมการอย่างรอบคอบและความใส่ใจในรายละเอียด. เริ่มต้นด้วยการเลือกฟิล์มและหมึกคุณภาพสูงที่ออกแบบมาสำหรับกระบวนการ DTF โดยเฉพาะ. การใช้วัสดุที่มีคุณภาพต่ำอาจส่งผลเสียต่อความมีชีวิตชีวาและความทนทาน.

การตั้งค่าอุณหภูมิและความดันก็มีความสำคัญเช่นกันเมื่อใช้งานเครื่องรีดความร้อน. ปฏิบัติตามหลักเกณฑ์ของผู้ผลิตเสมอเพื่อให้แน่ใจว่ามีการยึดเกาะที่แข็งแรงและสีสันที่สดใส. คุณอาจต้องทดลองเพื่อหาการตั้งค่าที่เหมาะสมที่สุดสำหรับผ้าแต่ละชนิด.

การบำรุงรักษาเป็นประจำถือเป็นสิ่งสำคัญเพื่อป้องกันการหยุดทำงานที่มีค่าใช้จ่ายสูงและรักษาคุณภาพการพิมพ์ที่สม่ำเสมอ. ทำความสะอาดหัวพิมพ์อย่างสม่ำเสมอและตรวจหาการอุดตันเพื่อให้การทำงานราบรื่น. กิจวัตรการบำรุงรักษาที่เชื่อถือได้จะช่วยยืดอายุการใช้งานอุปกรณ์ของคุณด้วย.

ในที่สุด, ลงทุนเวลาในการสร้างไฟล์อาร์ตเวิร์คที่เตรียมไว้อย่างดี. การออกแบบที่มีความละเอียดสูงช่วยให้มั่นใจได้ว่างานพิมพ์ขั้นสุดท้ายของคุณตรงตามความคาดหวังและเก็บรายละเอียดได้อย่างแม่นยำ. การใช้ซอฟต์แวร์ออกแบบกราฟิกที่ปรับให้เหมาะกับเวิร์กโฟลว์ DTF จะทำให้กระบวนการนี้มีประสิทธิภาพมากยิ่งขึ้น.

- สร้างไฟล์อาร์ตเวิร์คที่มีความละเอียดสูง

- คัดสรรฟิล์มและหมึกพิมพ์ที่มีคุณภาพ

- ปฏิบัติตามการตั้งค่าการกดความร้อน

- บำรุงรักษาเครื่องพิมพ์อย่างสม่ำเสมอ

การบำรุงรักษาและการแก้ไขปัญหาสำหรับเครื่องพิมพ์ DTF

การบำรุงรักษาเครื่องพิมพ์ DTF อย่างเหมาะสมทำให้มั่นใจได้ถึงความน่าเชื่อถือในระยะยาวและประสิทธิภาพที่สม่ำเสมอ. ทำความสะอาดหัวพิมพ์เป็นประจำเพื่อป้องกันการอุดตันที่อาจส่งผลต่อคุณภาพการพิมพ์, และใช้น้ำยาทำความสะอาดที่ผู้ผลิตแนะนำเสมอเพื่อผลลัพธ์ที่ดีที่สุด.

ตรวจสอบระดับหมึกบ่อยๆ เพื่อหลีกเลี่ยงการหยุดชะงักระหว่างการผลิต. หมึกเหลือน้อยอาจทำให้งานพิมพ์ซีดจางและรบกวนขั้นตอนการทำงานของคุณ, ดังนั้นจึงควรเก็บตลับหมึกสำรองไว้ใกล้ตัวเพื่อลดเวลาหยุดทำงาน.

แก้ไขปัญหาเล็กๆ น้อยๆ ทันทีเพื่อป้องกันไม่ให้กลายเป็นปัญหาใหญ่. หากคุณสังเกตเห็นเส้นหรือริ้วบนงานพิมพ์ของคุณ, ตรวจสอบการตั้งค่าการจัดตำแหน่งและการสอบเทียบ. การตรวจสอบหัวฉีดอย่างรวดเร็วสามารถช่วยพิจารณาว่าจำเป็นต้องมีการบำรุงรักษาเชิงลึกมากขึ้นหรือไม่.

ในที่สุด, อัปเดตเฟิร์มแวร์เครื่องพิมพ์ของคุณให้ทันสมัยอยู่เสมอเพื่อรับประโยชน์จากการปรับปรุงประสิทธิภาพและคุณสมบัติใหม่. ตรวจสอบการอัปเดตของผู้ผลิตเป็นระยะเพื่อให้แน่ใจว่าเครื่องพิมพ์ของคุณยังคงทำงานได้อย่างเต็มประสิทธิภาพ.

- ทำความสะอาดหัวพิมพ์อย่างสม่ำเสมอ

- ตรวจสอบและรักษาระดับหมึก

- แก้ไขปัญหาคุณภาพการพิมพ์โดยทันที

- อัพเดตเฟิร์มแวร์สำหรับคุณสมบัติใหม่

อนาคตของเทคโนโลยีการพิมพ์ DTF

เทคโนโลยีการพิมพ์ DTF มีการพัฒนาอย่างต่อเนื่อง, ด้วยความก้าวหน้าการปรับปรุงความเร็ว, คุณภาพ, และประสิทธิภาพโดยรวม. นวัตกรรมใหม่ของหมึกและฟิล์มช่วยให้งานพิมพ์มีสีสันสดใสและทนทานยิ่งขึ้น, ช่วยให้ธุรกิจต่างๆ สามารถตอบสนองความต้องการที่เพิ่มขึ้นสำหรับผลิตภัณฑ์สั่งทำพิเศษคุณภาพสูง.

การพัฒนาในอนาคตมีแนวโน้มที่จะให้ความสำคัญกับแนวทางปฏิบัติที่เป็นมิตรต่อสิ่งแวดล้อมมากขึ้น. เนื่องจากความยั่งยืนกลายเป็นเรื่องสำคัญระดับโลก, อุตสาหกรรมกำลังมุ่งสู่การลดของเสียและใช้วัสดุที่รับผิดชอบต่อสิ่งแวดล้อมมากขึ้น ซึ่งสอดคล้องกับความคาดหวังของผู้บริโภคและมาตรฐานอุตสาหกรรม.

ขอบเขตของแอปพลิเคชัน DTF ก็คาดว่าจะขยายออกไปเช่นกัน. นอกเหนือจากสิ่งทอ, เครื่องพิมพ์ DTF อาจพบว่ามีการใช้งานเพิ่มขึ้นในภาคส่วนต่างๆ เช่น บรรจุภัณฑ์, เครื่องประดับ, และแม้กระทั่งอุปกรณ์อิเล็กทรอนิกส์. ความคล่องตัวนี้จะขยายขอบเขตทางอุตสาหกรรมของเทคโนโลยีและเปิดโอกาสใหม่สำหรับนวัตกรรม.

นอกจากนี้, ความก้าวหน้าด้านปัญญาประดิษฐ์และระบบอัตโนมัติจะช่วยปรับปรุงขั้นตอนการผลิต. การแทรกแซงด้วยตนเองที่ลดลงและความแม่นยำที่ได้รับการปรับปรุงจะช่วยเพิ่มประสิทธิภาพ. เนื่องจากเทคโนโลยีเหล่านี้บูรณาการกันมากขึ้น, การพิมพ์ DTF พร้อมที่จะเปลี่ยนภูมิทัศน์การปรับแต่ง.

- การบูรณาการ AI และระบบอัตโนมัติ

- ความก้าวหน้าในด้านคุณภาพหมึกและฟิล์ม

- เน้นวิธีการที่เป็นมิตรต่อสิ่งแวดล้อม

- ขยายการใช้งานในอุตสาหกรรมต่างๆ

บทสรุป: เครื่องพิมพ์ DTF เหมาะสำหรับคุณหรือไม่?

การตัดสินใจว่าเครื่องพิมพ์ DTF เหมาะกับธุรกิจของคุณหรือไม่นั้นต้องอาศัยการประเมินปัจจัยสำคัญบางประการ. เริ่มต้นด้วยการพิจารณาปริมาณการผลิตและงบประมาณของคุณ. เครื่องพิมพ์ DTF มีประโยชน์อย่างยิ่งสำหรับธุรกิจที่เน้นเครื่องแต่งกายที่ออกแบบตามสั่งและต้องการความยืดหยุ่น, ความสามารถในการพิมพ์ตามความต้องการ.

คุณควรประเมินประเภทของเนื้อผ้าที่คุณวางแผนจะใช้ด้วย. เทคโนโลยี DTF ทำงานได้ดีกับผ้าฝ้าย, โพลีเอสเตอร์, และเนื้อผ้าผสม, ทำให้เป็นตัวเลือกอเนกประสงค์ที่สามารถตอบสนองความต้องการของลูกค้าได้หลากหลาย.

ในที่สุด, คำนึงถึงประโยชน์ระยะยาว เช่น ความทนทานและคุณภาพการพิมพ์. หากปัจจัยเหล่านี้สอดคล้องกับเป้าหมายของคุณ, เครื่องพิมพ์ DTF อาจเป็นการลงทุนที่มีมูลค่าสูง. ตัวเลือกที่เหมาะสมสามารถเปลี่ยนความสามารถในการพิมพ์และเพิ่มความเป็นไปได้ในการสร้างสรรค์ของคุณ.