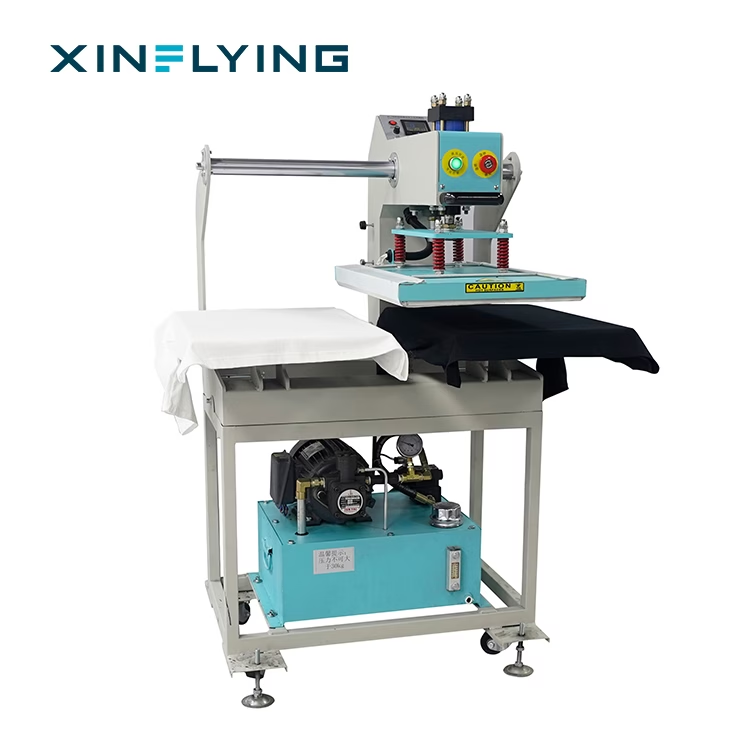

6040(7SER) Máquina de transferencia de calor hidráulica de doble estación semiautomática

Productos destacados:

1.Diseño hidráulico de doble estación

Permite cargar y prensar simultáneamente para mejorar la eficiencia de producción..

2.Presión uniforme & control de calor

El sistema hidráulico garantiza una presión constante y resultados de transferencia estables..

3.Fiable para un funcionamiento continuo

Diseñado para largas horas de trabajo en la producción textil y de prendas de vestir..

4.Aplicaciones versátiles de transferencia de calor

Adecuado para prendas, telas, y diversos materiales de transferencia de calor.

Funciones profesionales

Especificaciones del producto

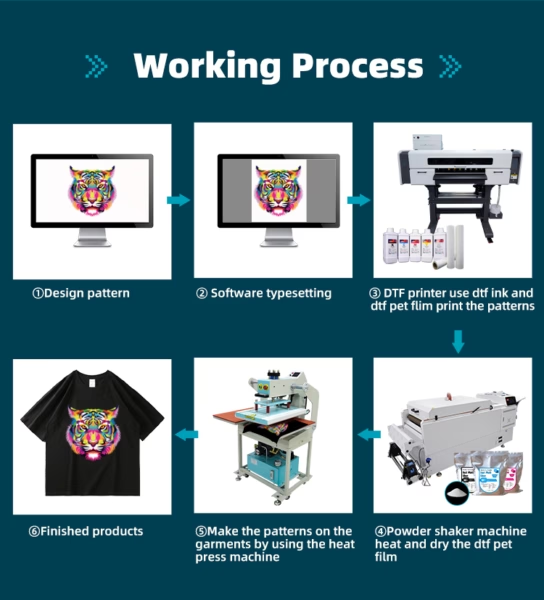

Proceso de impresión

Solicitud

Preguntas más frecuentes

Plataforma de trabajo de grado industrial equipada con una cubierta superior protectora. El diseño mejora la seguridad del operador al tiempo que mantiene un fácil acceso al área de prensado., adecuado para uso profesional continuo.

Estructura robusta del bastidor principal combinada con una caja de control integrada. Proporciona soporte mecánico sólido mientras alberga componentes eléctricos clave., garantizar una operación segura, durabilidad, y fácil acceso para mantenimiento.

Sistema de ajuste de presión de precisión integrado con componentes de control y marco de soporte.. Permite una regulación precisa de la fuerza de presión y la estabilidad operativa., mejorando la consistencia y reduciendo la fatiga del operador.

Unidad de prensa de calor completa con una placa calefactora superior reforzada y una mesa de trabajo inferior estable. Diseñado para una distribución uniforme de la presión y una transferencia de calor constante, Garantizar resultados fiables en una producción de larga duración..

| Modelo | 6040(7SER) |

|---|---|

| Tamaño de impresión | 60x40 |

| Voltaje (V) | 220V 1 fase/220V 3 fase/380v 3 fase |

| Límite de tiempo | 0-999S |

| Fuerza(kilovatios) | 4.3kilovatios |

| Rango de temperatura( °C) | 0-399 °C |

| Tamaño de la máquina | 100*82*140CENTÍMETRO |

| Tamaño del paquete | 195* 85*140CENTÍMETRO |

| Peso neto | 209.5KG |

| Peso bruto | 280KG |

Cree la obra de arte utilizando un software de diseño profesional..

Ajustar el diseño y los colores en el software RIP.

Imprime el diseño para transferir.

Utilice una prensa térmica para transferir la imagen a una tela de poliéster. (190–210°C, 30-60 años).

Brillante, durable, y resultados duraderos.

Q1: ¿Cómo uso una máquina de prensa de calor??

A: Para usar una máquina de prensa de calor, simplemente configure la temperatura, presión, y tiempo según el material en el que esté imprimiendo. Coloca el artículo (P.EJ., camiseta) en la prensa de calor, posiciona tu diseño, cerrar la prensa, y aplicar calor y presión. Espere a que termine el cronómetro, luego elimina tu artículo.

Q2: ¿Puedo usar una máquina de prensado en caliente para todas las telas??

A: Sí, Las máquinas de prensado en caliente se pueden utilizar en la mayoría de las telas., incluyendo algodón, poliéster, y mezclas. Sin embargo, Diferentes tejidos pueden requerir diferentes ajustes de temperatura y tiempo., así que siempre verifique la tolerancia al calor de la tela.

Q3: ¿Cuál es la diferencia entre las máquinas de prensado en caliente hidráulicas y manuales??

A: Las máquinas hidráulicas de prensado en caliente utilizan presión hidráulica para una distribución uniforme, ofreciendo resultados más consistentes y mayor eficiencia, especialmente en producción de alto volumen. Las máquinas manuales requieren fuerza física para aplicar presión., que puede no ser tan consistente o eficiente para lotes más grandes.

Q4: ¿Puedo usar una máquina de prensado en caliente para sombreros??

A: Sí, especializado máquinas de prensado en caliente para sombreros Están disponibles para imprimir en sombreros., tapas, y otros sombreros. Estas máquinas están diseñadas para manejar la forma y curvatura únicas de los sombreros..

Ancho de impresión

Productividad

cabezal de impresión

Dimensión

Ancho de impresión

Productividad

cabezal de impresión

Dimensión

Ancho de impresión

Productividad

cabezal de impresión

Dimensión

Conozca más sobre nuestro DTF, DTG, impresoras de sublimación, y consumibles.

Conozca más sobre nuestro DTF, DTG, impresoras y consumibles de sublimación.