State-of-the-art printer built with advanced technology to offer high precision, speed, and stability to your business success.

The printer control panel offers an intuitive interface that allows operators to manage print settings, monitor real-time status, and ensure consistent output. Designed for business environments, it helps streamline workflow and improve overall printing efficiency.

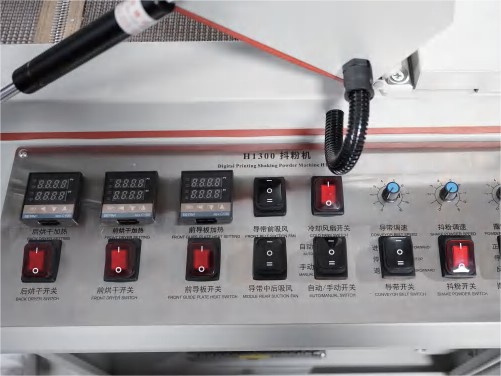

This dedicated control panel enables precise adjustment of temperature, speed, and vibration for the powder shaker. It ensures stable and uniform powder application—critical for achieving high-quality DTF prints in professional production settings.

The emergency switch provides immediate power cutoff to protect the operator and equipment. This safety feature is essential for any business-grade DTF printing setup, ensuring secure operation during intensive production.

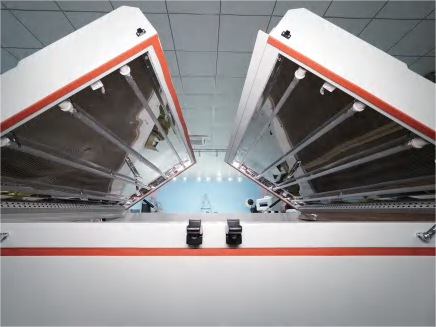

The curing oven delivers steady, high-temperature performance to ensure proper film curing and ink bonding. Its consistent heating control helps businesses achieve durable, wash-resistant prints while maintaining fast production speeds.

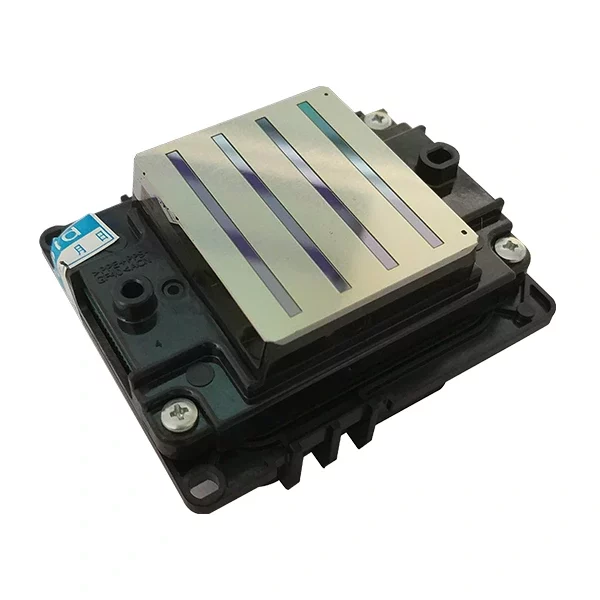

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | L1208 |

|---|---|

| Printhead and Quantity | 8pcs Epson i3200-A1 |

| Printing Speed | 4Pass:60m²/h |

| Printing Width | 48" |

| Media Type | DTF Pet Film |

| RIP Software | Standard with Printfactory ,Maintop, RIlN, PhotoPrint, CADlink for Optional |

| Temperature/Humidity | Temperature: 20-30 °C,Humidity: 45%-65%RH |

| Power / Voltage | 220V/110V;47A/94A ;50HZ/60HZ |

| Machine Size | L2843*W1772*H1076mm |

| Packing Size | L3800*W1750*H1250mm |

| Net Weight | 580KG |

| Gross Weight | 620KG |

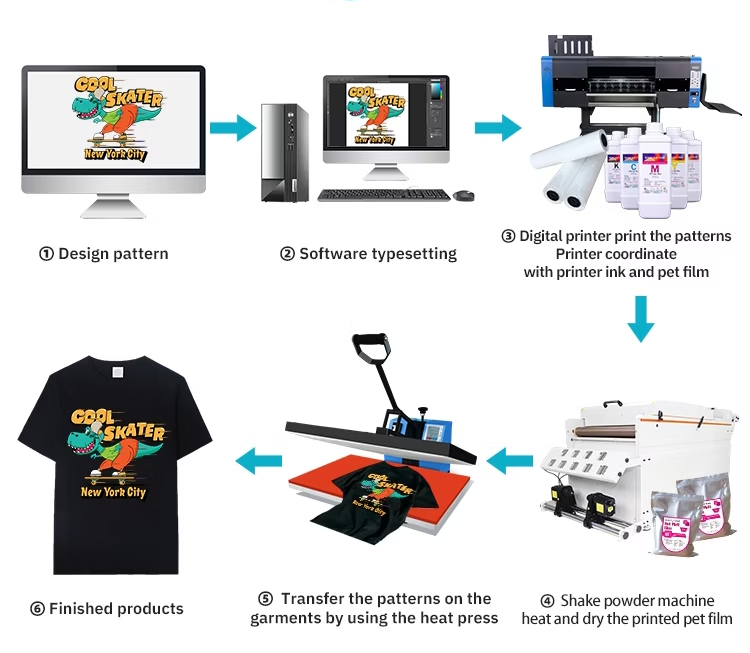

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.