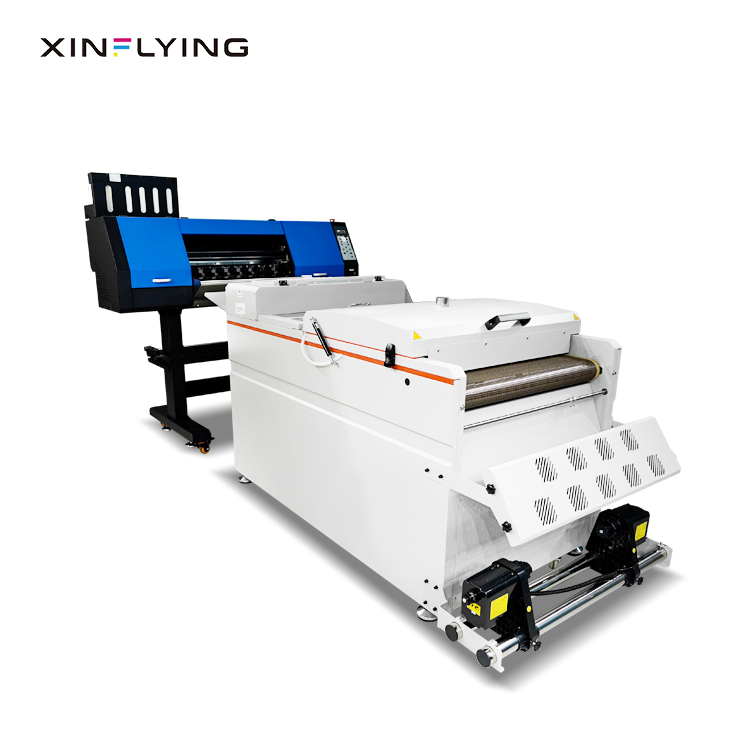

DTF Printer

- High precision print heads

- Suitable for wide range of fabrics

- Produces vivid colors image

- Higher production efficiency

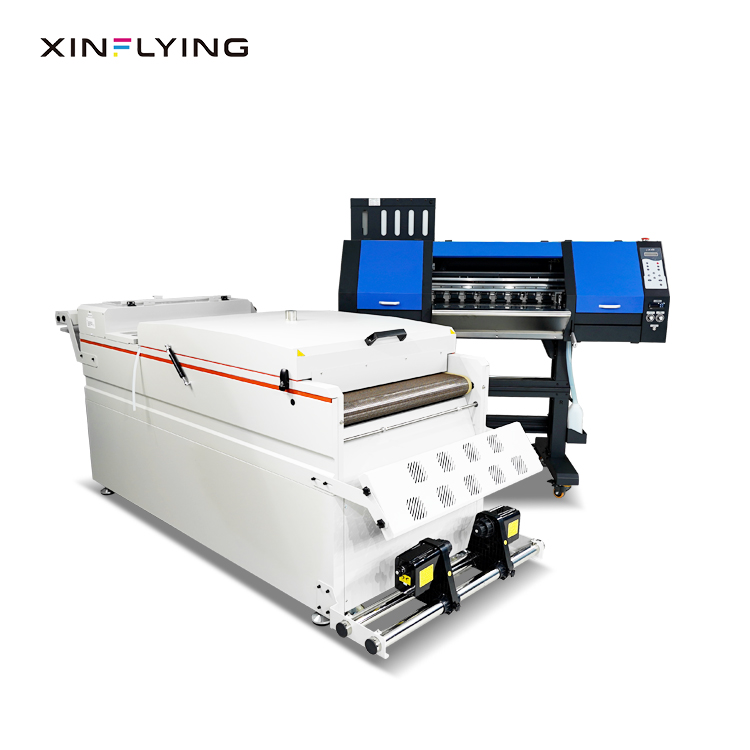

Diverse Printing Width for Business Goals

Whether you are an individual for a startup business or a mega enterprise, Xin Flying as a DTF printer supplier from China gets you covered at an affordable price. Both DTF printers or DTF powder shaker machines can be also split up for sale.

A3/A2 DTF Printer for Small Business & Startup

XF-450pro 2 Head All in One A2 DTF Printer

- Productivity: Pass: 10m²/h 6Pass: 8m²/h 8Pass: 6m²/h

-

Printing Width: 16‘’

-

Printhead: 2Pcs Epson i1600-A1/F1080-A1/XP600/i3200-A1Dimension: L1140*W1085*H1028mm

- Productivity: 8Pass: 1.2m²/h

- Printing Width: 13”

- Printhead: 1 PCS XP600

- Dimension: L790*450*460mm

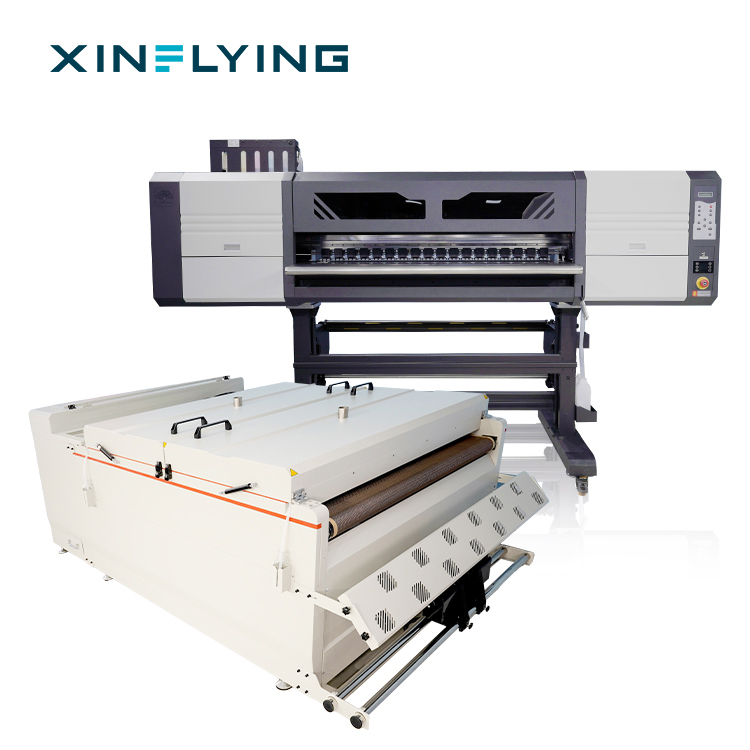

Best Commercial A1 DTF Printer for Large Format Printing

C605+H6502 5 Head 24‘’ I3200 DTF Printer

24”

6Pass: 36m²/h

5PCS I3200-A1

L1670*W815*H1600mm

L605+H6502 5 Head 24‘’ I3200 DTF Printer

24”

6Pass: 28m²/h

5PCS I3200-A1

L1670*W815*H1600mm

C602+H650 24 Inch I3200-A1 DTF Printer

24”

4Pass:12m²/h 6Pass:10m²/h 8Pass:8m²/h

2PCS I3200-A1

L2040mmxW740mmxH840mm

C602+C650H 24 inch 2 Heads DTF Printer

24"

4Pass:12m²/h 6Pass:10m²/h 8Pass:8m²/h

2PCS 13200-A1

L1660xW750xH1620mm

C604+H6501 24 inch DTF Printer

24”

4Pass: 24m²/h 6Pass:16m²/h

4PCS 13200-A1

L1670*W815*H1600mm

E602+H650 24 Inch 2 Heads A1 DTF Printer

0-600mm

12㎡/h (4 Pass)

2* Epson I3200-A1 (Optional 4720)

1660 x 750 x 1620mm

L1208+H1300 48 Inch I3200-A1 DTF Printer

48"

4Pass:74m²/h 6Pass: 48m²/h

8PCS Epson 13200-A1

L2860*W915*H1890mm

A0/120cm Professional DTF Printer with Superior Printing Performance

How to Choose Suitable DTF Printer for Your Business?

2 Heads DTF Printer

Suitable for small to medium-sized enterprises, offering a high cost-performance ratio and ease of operation, ideal for moderate production needs.

4 Heads DTF Printer

Suitable for medium-sized enterprises, capable of providing higher production efficiency and excellent print quality, suitable for diverse production requirements.

5 Heads DTF Printer

Suitable for medium to large enterprises, offering higher production efficiency and superior print quality, ideal for high-demand production tasks.

8 Heads DTF Printer

Suitable for large enterprises and factories, providing the highest production efficiency and best print quality, ideal for large-scale and high-end market production needs.

Latest Technology for Efficient Printing

Xinflying‘s DTF printers equipped with advanced technology and innovative systems that allow your DTF printing business to work easily and smoothly.

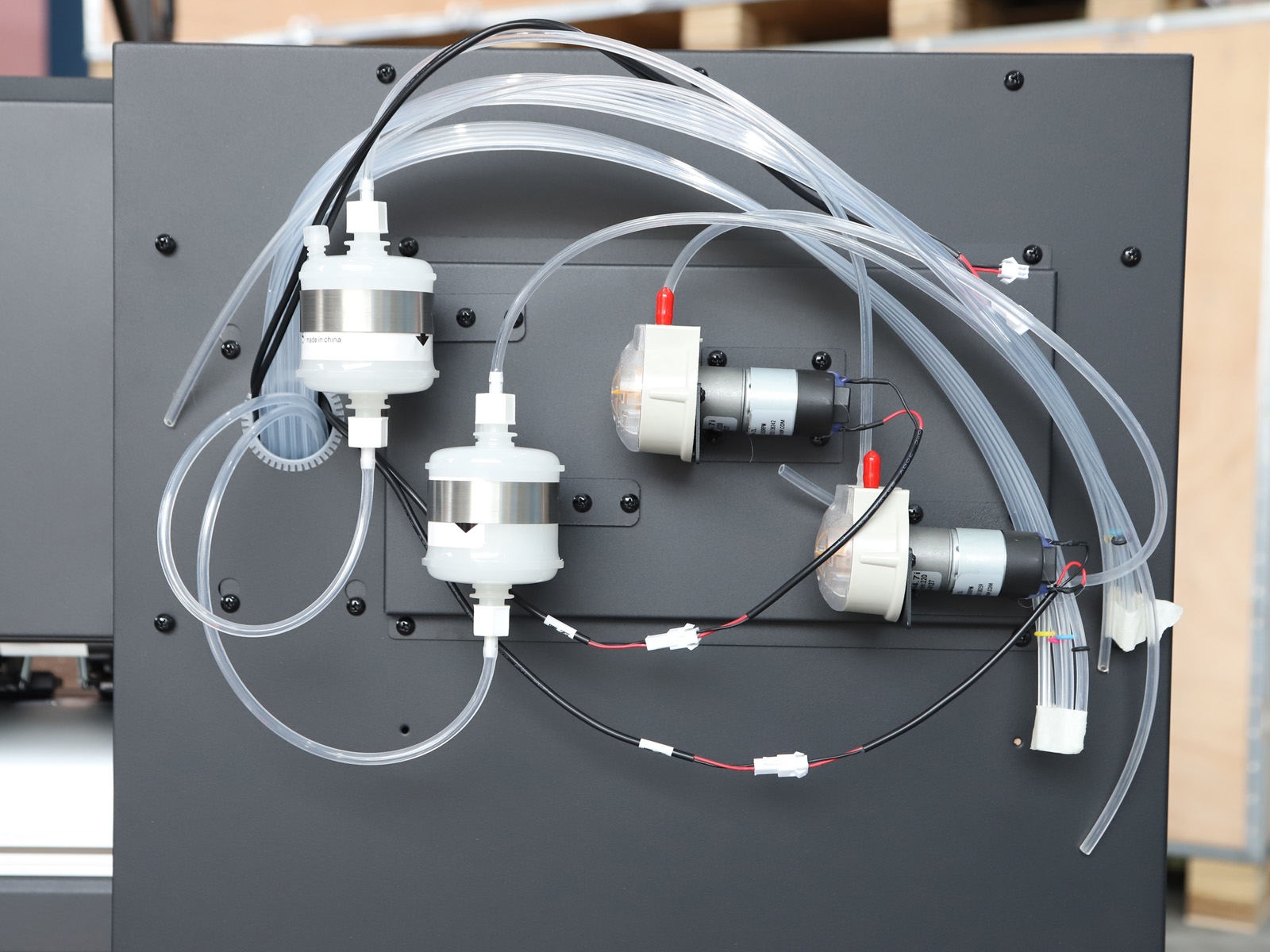

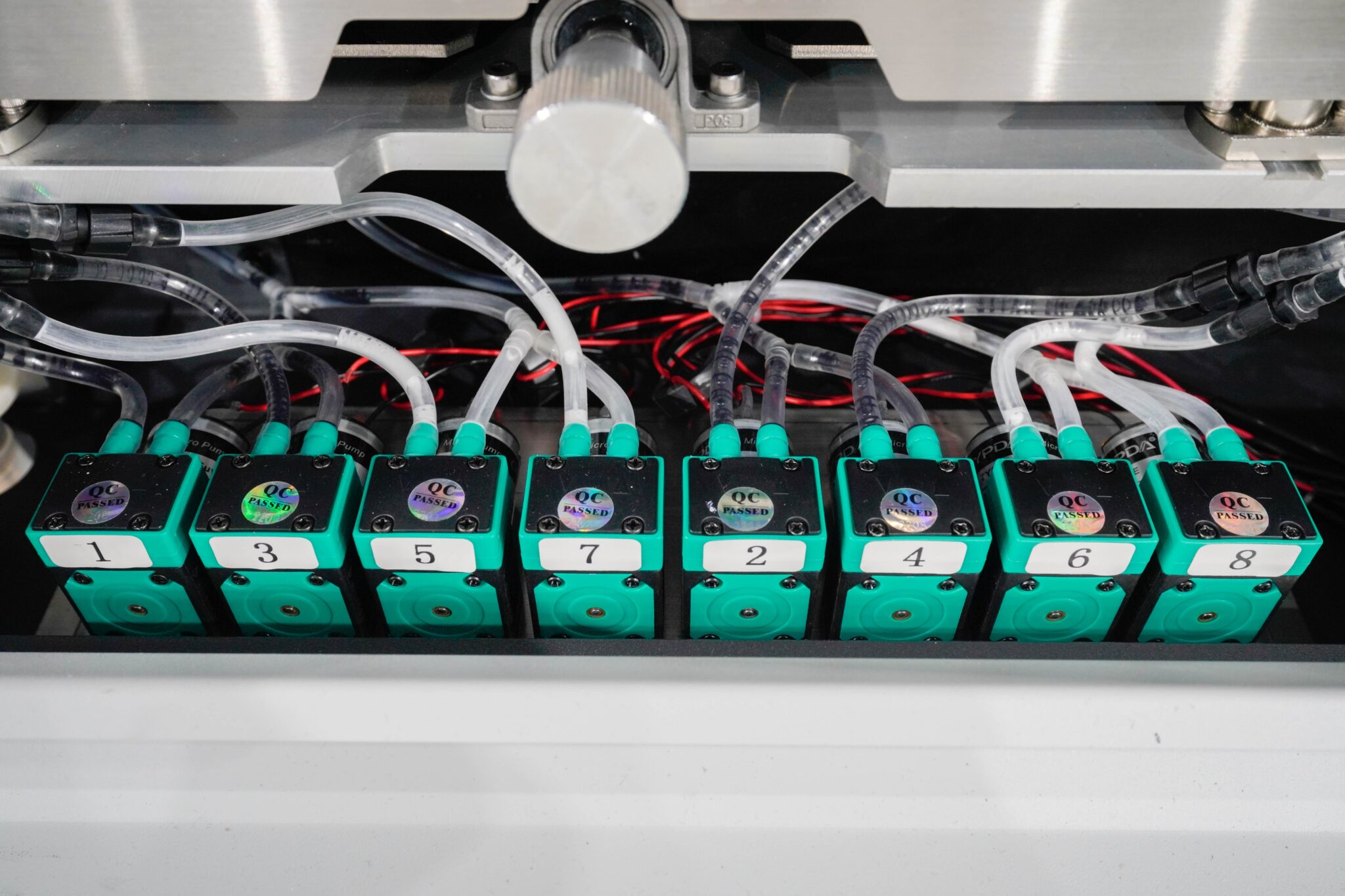

White Ink Circulation

For white ink with a higher density than normal color ink, to guarantee constant ink supply, Xin Flying's DTF printer is equipped with a latest system that allows white ink to be properly stirred and circulated to away from precipitation and clogging.

Air-absorbing printing platform

The pressure generated by the intake of air keeps the print film in close contact with the print platform at all times. Tests have shown us that this design improves the accuracy of the printer.

Ink pumps

One thing we all know is that white ink left for a long time will settle and then cause the print head to clog. To solve this problem we have equipped the printer with an ink pump. This is used to agitate the white ink and clean the print head at regular intervals to prevent damage to the print head caused by the white ink settling. Extending the life of the print head.

Advanced PrecisionCore Tech

Features a Micro-Electro-Mechanical System (MEMS) manufacturing and thin-film piezo element that can deliver precise and consistent positioning of round ink droplets. This contributes to the compactness, speed, and high image quality of prints.

What Can You Make With DTF Printing?

-

T-shirt

T-shirt

-

Cap

Cap

-

Hoodies

Hoodies

-

Shoes

Shoes

-

Canvas Bag

Canvas Bag

-

Pillow

Pillow

-

Backpack

Backpack

-

Jeans

Jeans

How do We Grow Your Business?

In-stock DTF Machine For Your Printing Business

- Saves time and human effort in bulk orders

- No Need to Make Plates, Flexible Batch, Not Limited Pattern

- More flexible for those only need DTF film as business

- Easy Installment with Guidance, Good Printing Effect

- We offer both online and door-to-door services

Start Printing Effortlessly

Free Demo & Sample

Free Demo & Sample

Fast Delivery

Fast Delivery

Technical Support

Technical Support

Life-time Warranty

Life-time Warranty

Difference Between DTF & DTG Printing

Direct to Films Printer

- Saves a lot of time and human effort in bulk orders.

- Suitable for many kinds of fabrics, such as cotton & poly blends.

- Wider application for shoes, cap, pillow and other apparels

- More flexible for those only need DTF film as business

Direct to Garments Printer

- Simple to print one-offs with no required setup time.

- The printing graphics can last for a longer time.

- Cost of printing on light garments is relatively low.

- The process is more eco-friendly without PET film & powder.

Compatible DTF Consumables

DTF Ink

PET Film

Adhesive Powder

Why DTF Printing is Popular for Textile Printing?

The combination of quality, versatility, and affordability contributes to its popularity for textile printing.

1. DTF printing offers vibrant and durable prints for T-shirts, hoodies, pants, etc.

2. It is versatile and compatible with various fabric types.

3. DTF printing allows for intricate designs and detailed graphics.

4. DTF printers are relatively affordable and easy to use.

5. It allows printing on items of various shapes and sizes without concern for the material’s color.

6. DTF printed images are highly resistant to washing and are not prone to fading or peeling.

How does a DTF Printer Work?

Design Creation

Create or obtain the design to be printed on the computer.

Print on Transfer Film

Print the design onto transfer film using a DTF printer with special DTF ink.

Apply Powder

Sprinkle a specially-formulated adhesive powder over the inked transfer film.

Heat Transfer

Place the transfer film with adhesive powder on top of the final material to be printed.

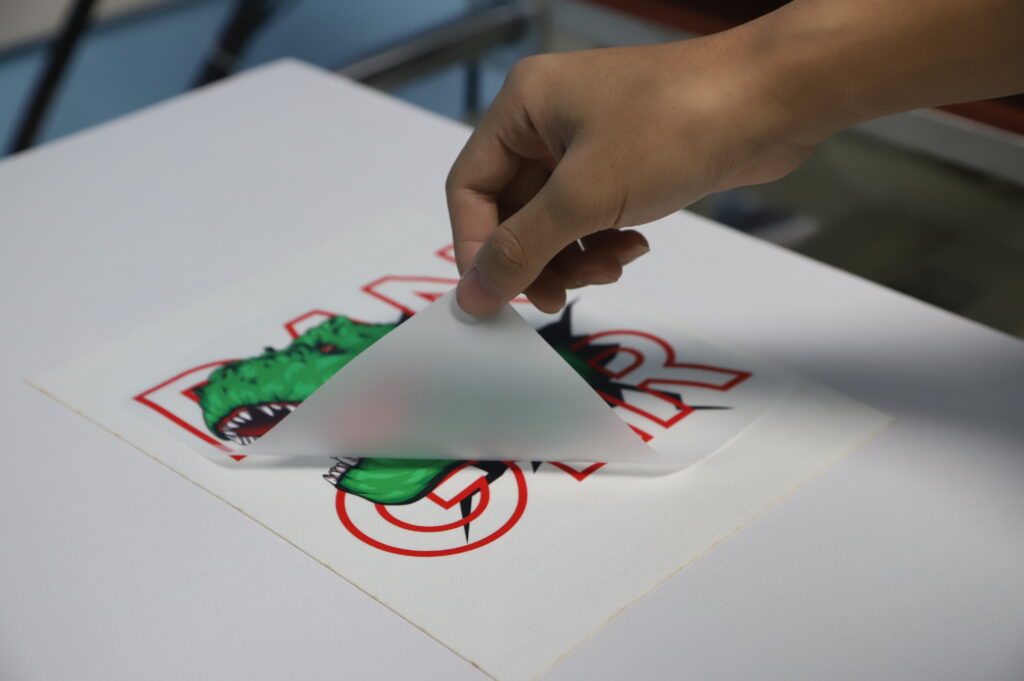

Peel off the Film

After heat pressing, carefully peeling off the transfer film to ensure the transferred image remains intact.

Diverse Applications of DTF Printing

DTF printers can print on a wide range of fabrics due to its versatility, including T-shirts, pants. hoodies, bags, hats, shoes and so on.

Apparel

DTF printers are perfect for creating custom t-shirts, hoodies, shoes etc. They allow for high-resolution, full-color printing directly on to fabric, making it possible to create extremely detailed designs.

Home Decor

DTF printing is used to create personalized cushions, curtains, tablecloths, pillows on a variety of fabrics. This can help in creating unique and personalized home décor.

Personalized Gifts

DTF printing is great for making personalized gifts. One can print high-quality images directly on to items like totes, aprons, hats etc., for a unique and personal present.

Key Advantages of DTF Printer

1. Lower Cost

DTF printing offers lower setup and production costs than traditional screen printing methods.

2. Versatility

DTF printers can print on a wide range of substrates, including textiles, ceramics, plastics, and even metal.

3. Durability

4. Exceptional Quality

5. Fast Production

6. No Color Limitations

FAQs on DTF Printers

1. What do you need for DTF printing?

You need a DTF printer, PET films, DTF ink, hot melt adhesive powder and a heat press.

2. How much is a DTF printer?

The cost of a DTF printer can range from around $3,000 to $15,000 or more, depending on the model, print head configuration, and additional features.

3. Which is better, DTF vs. sublimation?

DTF is better for printing on a wider variety of fabrics, including dark and non-polyester materials, and provides vibrant colors and durable prints. Sublimation is ideal for polyester fabrics and hard surfaces with a special coating, offering excellent color vibrancy and durability but limited to light-colored substrates.

4. Which is better, DTG or DTF?

DTF is often preferred for its versatility in fabric types and ability to print on dark fabrics without pretreatment. DTG printing provides excellent print quality and is great for cotton fabrics but requires pretreatment for dark fabrics and is generally less versatile in terms of material compatibility.

Tips & Tricks for Achieving the Best DTF Printing

- Inks and Powder Quality: Use high-quality ink and powder specifically formulated for DTF printing.

- Surface Preparation: Clean, dry, and free from dust or lint surface to be printed on and pre-treatment solutions applied.

- Color Separation: Properly separate different color channels to accurately reproduce designs.

- Ink Density: Adjust ink density to achieve maximum saturation without ghosting or smudging.

- Curing Temperature: Balance curing temperature and time according to the substrate.

- Proper Maintenance of Printer: ERegular maintenance of the DTF printer is necessary to ensure optimal performance.

- Humidity: Proper humidity control measures should be used in the print room to avoid affecting ink curing and print quality.

.jpg)