DTG Printer

Explore Xin Flying DTG Printers

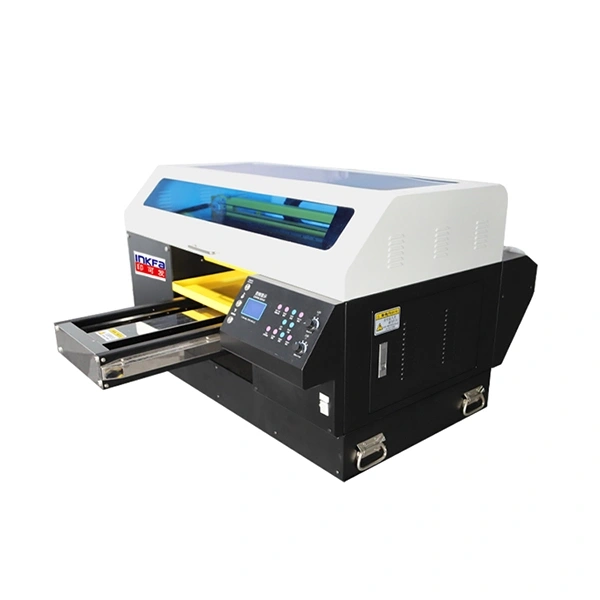

XF-DTG-2 DTG Printer

450*550mm/950*650mm

A3 size 2min/per

2/4* Epson I3200-A1/4720

1628 x 2200x 1281mm

Adavanced Technology for Efficient Printing

A variety of state-of-the-art technology for the best direct-to-garment printer to make your business run smoothly and effortlessly.

White Ink Circulation

Automatic Lifting System

Multiple Printing Platforms

Various Applications on DTG Printer

Start Printing Effortlessly

Free Demo & Sample

Free Demo & Sample

Fast Delivery

Fast Delivery

Technical Support

Technical Support

Life-time Warranty

Life-time Warranty

Difference Between DTF & DTG

Direct to Films Printer

- Saves a lot of time and human effort in bulk orders.

- Suitable for many kinds of fabrics, such as cotton & poly blends.

- Wider application for shoes, cap, pillow and other apparels

- More flexible for those only need DTF film as business

Direct to Garments Printer

A digital direct-to-garment printing method that involves the spraying of ink onto a garment, which then soaks into the fibers. As for application, DTG can only work on cotton. The working process is consist of 4 steps: pre-treatment, drying, printing, and curing.

- Simple to print one-offs with no required setup time.

- The printing graphics can last for a longer time.

- Cost of printing on light garments is relatively low.

- The process is more eco-friendly without PET film & powder.

What is DTG Printing?

How does a DTG Printer Work?

Design & Setup

Create or select the design, prepare the printer with the correct settings, and ensure the garment platen is clean.

Pre-treat the Garment

Before printing, prepare the garment by flattening and smoothing it using a heat press.

Print on Garment

Initiate the print job using the DTG printer software, which will accurately apply the ink directly onto the fabric.

Curing

After printing, the garment needs to be cured or dried to permanently set the ink by using a heat press or a conveyor dryer.

What can DTG Printers Print on?

Cotton

Polyester

Denim

Silk

Synthetic Fabrics

Sublimation vs. DTG vs. DTF Printing

| Type | Sublimation Printing | DTG (Direct-to-Garment) Printing | DTF (Direct-to-Film) Printing |

|---|---|---|---|

| Process | Heat is used to transfer dye onto polyester or polymer-coated substrates. | Water-based ink is directly printed onto the garment or fabric. | Heat is used to transfer printed film onto garments or other substrates. |

| Fabric | Works best on polyester and polymer-coated items. | Varieties of fabrics including cotton, blends, and polyester. | Works on multiple fabric types. |

| Color | Vibrant and long-lasting colors. | Good color reproduction. | Excellent color saturation and vibrancy. |

| Print Quality | High resolution with smooth gradients and color transitions. | Capable of reproducing intricate details and complex designs. | High level of detail and clarity. |

| Production Speed | Quick production time. | Fast production speed for single or small quantity prints. | Fast and efficient production process. |

| Cost | Initial investment in printer, ink, and heat press equipment. | Moderate initial investment. | Moderate initial investment. |

| Versatility | Limited to polyester and polymer-coated substrates. | Versatile for various fabric types and textures. | Versatile for different fabric types and substrates. |

| Special Considerations | Requires specific ink and sublimation-compatible substrates. | Pre-treatment may be required for some fabrics. | Requires printed films and adhesive powder/ink. |