Product Highlights:

1. Dual-System Stability with Hoson Control Board

Printer equipped with Hoson controller delivers reliable, high-precision printing performance.

2. Advanced Ink Management & Alert Systems

Includes automatic humidification, motorized pressure roller lift, ink shortage alarm, waste-ink full alarm, and white ink circulation & stirring system to ensure smooth long-term operation.

3. Integrated Intelligent Powder Shaker

Automatic powder spreading with vibration shaking, mesh belt conveyor, and sensor-based take-up significantly reduces manual labor.

4. Complete Thermal & Cooling System

Infrared heating tubes combined with a cooling system ensure stable curing, better adhesion, and consistent output quality.

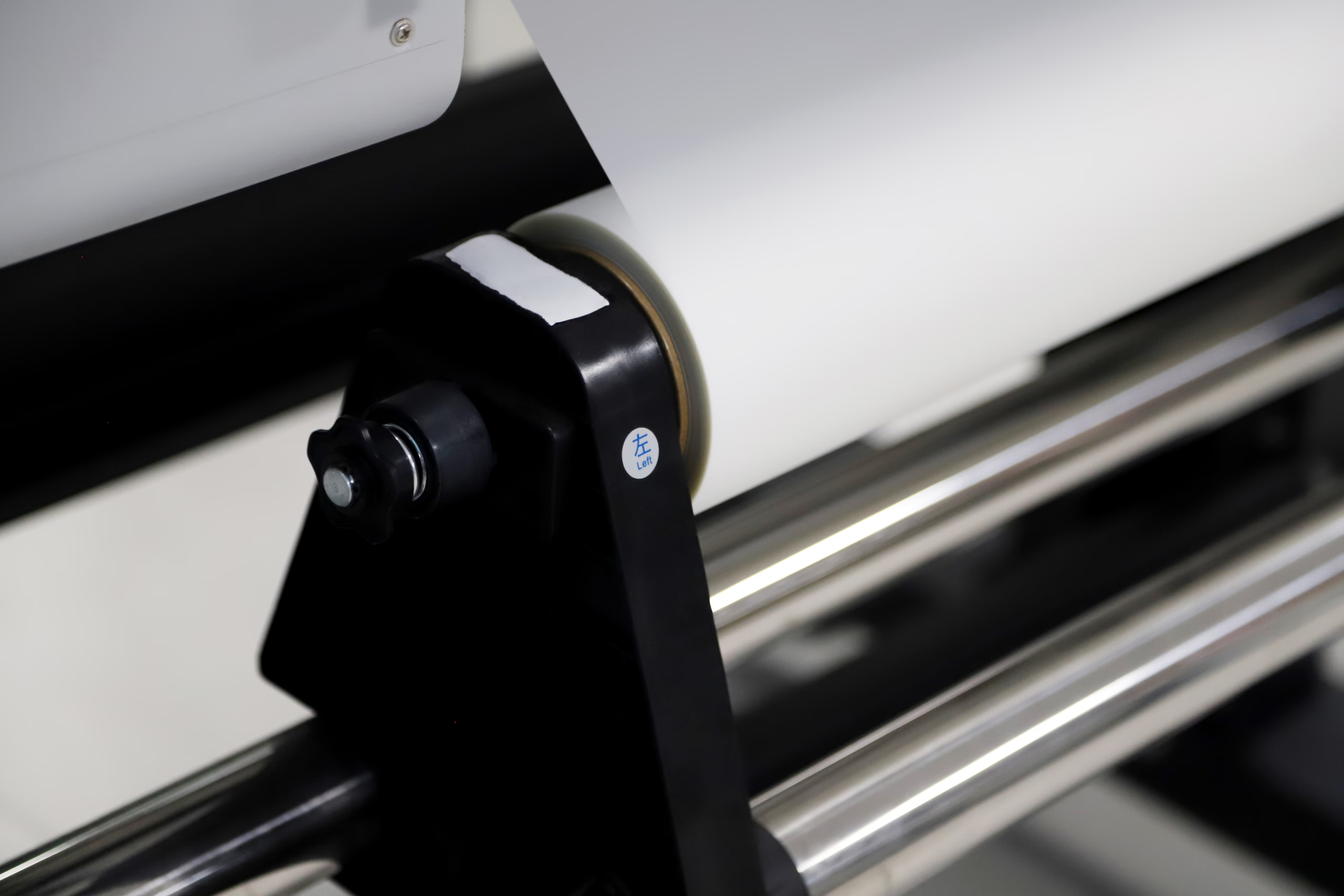

Experience ultra-smooth carriage stability with the imported HIWIN rail system. Ideal for dtf printers, it ensures precision movement, reduced vibration, and long-term durability for professional direct to film printing performance.

A user-friendly control panel allows operators to manage essential dtf printer functions, adjust settings, and monitor status—ideal for dtf printer for beginners and fast-paced production environments.

The automatic moisturizing system prevents nozzle drying during downtime, extending head lifespan and improving uptime—essential for continuous DTF machine printer production and T-shirt printing operations.

Our advanced cartridge system ensures stable ink delivery and easy replacement. Designed for direct to film printers, it reduces clogging and maintains high-quality output while simplifying maintenance for busy T-shirt printing shops.

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | 702E |

|---|---|

| Printhead and Quantity | 2pcs Epson i3200-A1 |

| Printing Speed |

6PASS:10m²/h 8PASS:8m²/h 12PASS:5m²/h |

| Printing Color | CMYK+W |

| Printing Width | 24" |

| Media Type | DTF Pet Film |

| RIP Software |

Standard with Printfactory ,Maintop, RIlN,

PhotoPrint, CADlink for Optional |

|

Temperature/

Humidity |

20-30 °C; 45%-65%RH |

| Power / Voltage | 0.8KW;220V/110V;50HZ/60HZ |

| Machine Size | L1700*W850*H1350mm |

| Packing Size | L1800*W880*H680mm |

| Net Weight | 158KG |

| Gross Weight | 194KG |

_05-600x515.avif)

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Q1: What businesses is it ideal for?

A: Designed for small and medium businesses, the dual-head configuration ensures fast, high-quality DTF printing suitable for custom apparel shops.

Q2: Consumables needed?

A: Uses DTF inks, PET film, and hot-melt powders, optimized for minimal waste and high efficiency.

Q3: How is shipping secured?

A: Packed in reinforced wooden crates with foam, safe for international and domestic shipping.

Q4: Warranty and support?

A: Comes with 1-year warranty on major components and lifetime support, including installation guidance and troubleshooting.

Q5: What fabric types can it handle?

A: Compatible with cotton, polyester, and blended fabrics, producing vibrant and long-lasting prints.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.