Product Highlights:

1. Stable Hoson Control Board

Professional Hoson controller ensures stable data processing and consistent printing performance.

2. Automatic Humidification System

Maintains optimal humidity around printheads to reduce clogging and extend printhead lifespan.

3. Motorized Pressure Roller Lift

One-touch motorized lifting improves operational convenience and ensures consistent pressure during printing.

4. Ink Shortage Alarm System

Real-time ink monitoring alerts users in advance, preventing print interruptions and material waste.

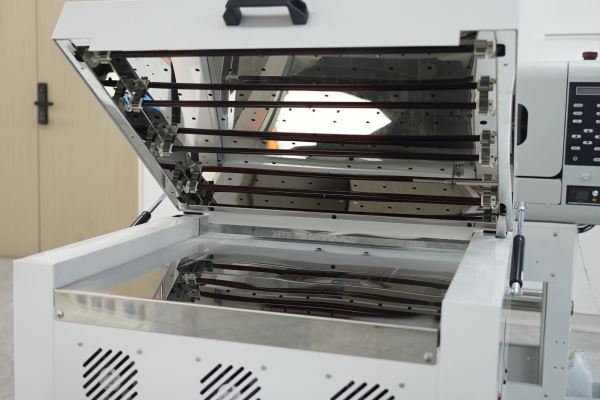

Built with a preheating and powder shaking system that ensures great efficiency in the drying and curing process of PET film without ink smudge.

Comes with a rotatable smart touch control panel, enabling easy navigation and operation of the whole printer. Also, it supports different languages, allowing you to choose your preferred choice.

Comes with a built-in powder shaking machine that’s different from the normal separated ones in the market. It saves a lot of space and cost while still maintaining an exclusive performance to spreading evenly.

With a consistent ink supply and circulation system, white ink is stirred effectively to avoid precipitation and clogging, ensuring smooth printing and low maintenance.

| Model | I1600-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 1600 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 4 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 80g |

| Model | XF-A2 |

|---|---|

| Print Head | 2PCS Epson i1600-A1 |

| Print Width | 16.5" |

| Printing Speed |

6PASS:9m²/h 8PASS:7m²/h 12PASS:5m²/h |

| Rated Power | 0.8KW |

| Color | CMYK +W |

| RIP Software | Standard with printfactory & maintop ,Photoprint & Cadlink for Optional |

| Power Supply/Voltage | 220 V/110 V ; 3.6A/7.3A ; 50Hz-60Hz |

| Packing Size | L1100*W510*H625mm |

| Machine Size | L1110*W560*H770mm |

| Net Weight | 65KG |

| Gross Weight | 85KG |

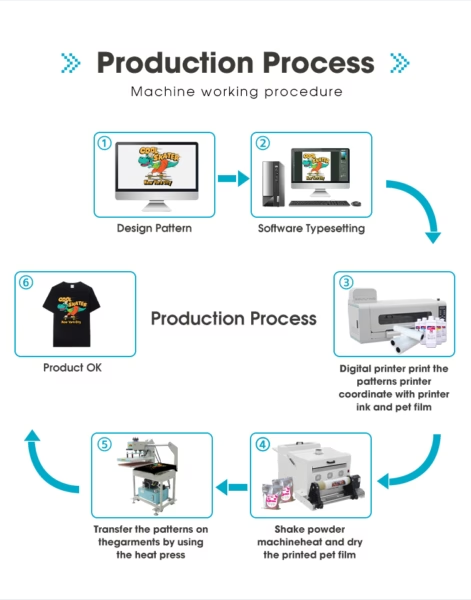

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Q1: What is this A2 DTF printer mainly used for?

A: It is used for professional A2-size DTF transfer printing, suitable for apparel logos, graphics, and medium-sized designs.

Q2: What printhead configuration does it use?

A: The printer features dual Epson I1600-A1 printheads, balancing speed, precision, and cost efficiency.

Q3: Is this model suitable for commercial production?

A: Yes. It supports stable, daily production for small to medium printing shops.

Q4: Can it work with an external powder shaker?

A: Yes. It can be paired with a matching powder shaker to form a complete DTF printing line.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.