DTF printing, short for Direct-to-Film printing, is a groundbreaking method that has revolutionized the printing industry. It offers a versatile and efficient solution for transferring designs directly onto fabrics and various materials. Unlike traditional methods, DTF printing eliminates the need for intermediate steps like screen preparation or heat transfer sheets, allowing for quick and precise results.

This comprehensive guide is designed to introduce beginners to the world of DTF printer. Whether you’re a hobbyist exploring new creative avenues or a small business owner looking to expand your product line, understanding the basics of DTF printing will unlock a world of possibilities. From the working process to its applications and advantages, this guide will provide you with the fundamental knowledge to embark on your DTF printing journey. So, let’s dive in and explore the exciting realm of DTF printing together.

What is DTF Printing?

DTF printing, or Direct-to-Film printing, is a modern printing technique that enables the direct transfer of designs onto fabrics and various substrates. It utilizes a specialized process that involves the use of adhesive, heat, and pressure to create vibrant and durable prints.

One key difference between DTF printing and other printing methods, such as screen printing or heat transfer printing, is the elimination of color separation and the ability to achieve full-color prints without layering. DTF printing allows for intricate and complex designs with vibrant colors, making it a preferred choice for customization and detailed graphics. Additionally, the versatility of DTF printing extends beyond fabrics to include materials like ceramics, wood, metal, and more, expanding its applications in various industries.

Applications of DTF Printing

DTF printing has found extensive applications across numerous industries, thanks to its versatility and ability to produce high-quality prints on a wide range of materials. Here are some key areas where DTF printing is utilized:

1. Fashion and Apparel Industry

DTF printing has gained significant popularity in the fashion and apparel industry. It offers the ability to print intricate designs, patterns, and logos directly onto garments, including t-shirts, hoodies, leggings, and more. The vibrant colors and excellent durability of DTF prints make them ideal for creating custom clothing and unique fashion pieces.

2. Home Decor

DTF printing has also made its mark in the world of home decor. It allows for the customization of items like cushions, curtains, tablecloths, and upholstery with personalized designs, text, or images. This enables individuals to add a personal touch to their living spaces and create visually stunning interiors.

3. Promotional Products

DTF printing is an effective method for creating promotional products. It enables businesses to print their logos, slogans, and branding elements on various items, including bags, caps, mugs, and phone cases. The versatility of DTF printing ensures that promotional products stand out and leave a lasting impression on recipients.

4. Customization

One of the significant advantages of DTF printing is its customization capabilities. It allows individuals and businesses to create unique, one-of-a-kind items by printing personalized designs, names, or photographs. From customized gifts to personalized merchandise, DTF printing offers endless creative possibilities.

The versatility of DTF printing extends to the wide range of materials it can print on. In addition to fabrics like cotton, polyester, and blends, DTF can be used on materials such as ceramics, wood, metal, glass, and even leather. This expands the potential applications of DTF printing beyond apparel and encompasses products like mugs, tiles, signage, personalized gifts, and more.

With its ability to achieve vibrant colors, intricate details, and excellent durability on diverse materials, DTF printing has become a highly sought-after printing method across various industries, offering endless opportunities for customization and creativity.

How does DTF Printing Work?

If you’re a beginner interested in diving into the world of DTF printing, here’s a step-by-step guide to help you get started:

1. Gather the Essential Equipment and Materials

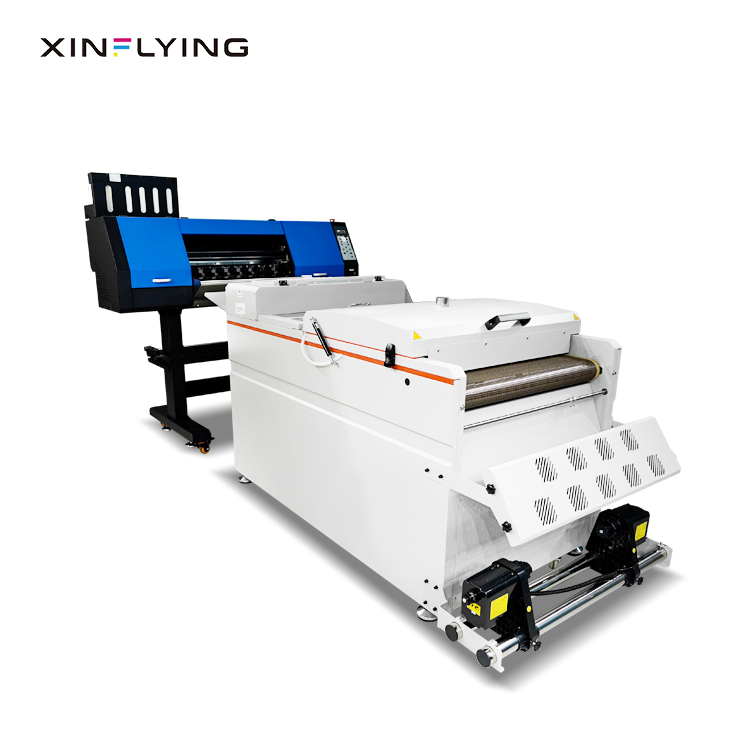

- DTF Printer: Invest in a reliable DTF printer capable of handling the size and types of prints you intend to produce.

- DTF Inks: Use eco-solvent or water-based DTF inks compatible with your printer.

- DTF Film: Get DTF transfer films suitable for your printer to serve as carriers for your designs.

- Adhesive Sheets: Acquire heat-activated adhesive sheets that work well with DTF printing.

- Heat Press Machine: Purchase a high-quality heat press machine capable of providing consistent heat and pressure.

2. Design Creation and Adjustment

Use graphic design software to create or modify your design. Ensure it is in a suitable format for printing, such as JPEG or PNG. Then adjust the color profile and ensure the image resolution is appropriate for clear and sharp prints.

3. Pre-Treatment

For fabric printing, pre-treat the material with a pre-treatment solution specifically formulated for DTF printing. This helps improve ink adhesion and color vibrancy.

4. Printing Setup

Load the DTF transfer film into your printer, making sure it is properly aligned and configure the printing settings, such as ink density, print resolution, and drying time, based on the DTF printer manufacturer‘s recommendations.

5. Printing

Send the designed image to the DTF printer and initiate the printing process. Ensure the ink is adequately cured before touching the printed film to prevent smudging or damage.

6. Transfer Process

- Cut out the printed design from the DTF transfer film, leaving a small border around the edges.

- Place the heat-activated adhesive sheet onto a heat press machine.

- Position the printed film on top of the adhesive sheet, ensuring it aligns with the design.

- Apply heat and pressure using the heat press machine, following the recommended temperature and time settings for your specific materials.

7. Peel and Finish

After the heat press process, carefully peel off the film from the adhesive. Ensure the design adheres properly to the target material. Allow the finished product to cool before handling or further processing.

By following this step-by-step guide, you’ll be well on your way to mastering DTF printing. Remember to familiarize yourself with the specific instructions provided by the DTF printer manufacturers to ensure optimal results. Practice, experimentation, and attention to detail will help you refine your skills and achieve high-quality DTF prints.

Tips for Successful DTF Printing

To help you achieve optimal results with DTF printing, here are some practical tips and best practices:

1. Optimal Temperature, Pressure, and Timing

- Ensure the heat press machine is set to the recommended temperature specified by the adhesive sheet and transfer film manufacturers. This temperature ensures proper activation of the adhesive and ink transfer.

- Adjust the pressure on the heat press machine according to the thickness and type of material you’re printing on. Sufficient pressure ensures proper adhesion and ink penetration.

- Follow the recommended time settings for the specific materials you’re using. Proper timing ensures adequate heat exposure without causing damage to the substrate or print.

2. Proper Film Alignment

- Align the printed film accurately with the adhesive sheet during the transfer process. Misalignment can result in skewed or distorted prints.

- Use registration marks or alignment guides to ensure consistent and precise placement.

3. Test Prints and Color Calibration

- Perform test prints on sample materials before proceeding with full production. This allows you to fine-tune parameters such as color saturation, sharpness, and image positioning.

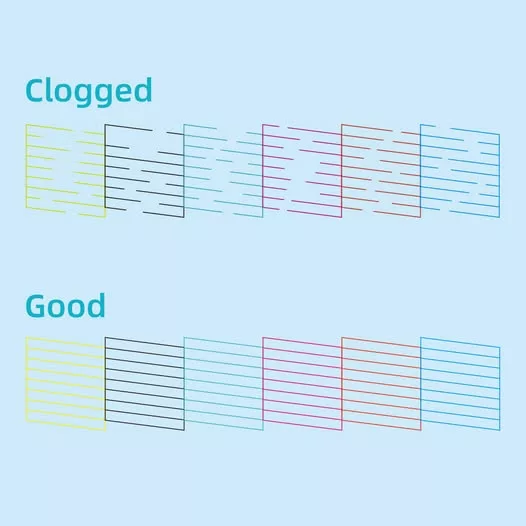

- Calibrate your printer regularly to maintain accurate color reproduction and image quality.

4. Handling and Storage

- Handle the DTF transfer films with clean, dry hands to avoid fingerprints or smudges that can affect print quality.

- Store unused transfer films in a cool, dry place, away from direct sunlight, moisture, and extreme temperature fluctuations.

5. Troubleshooting Common Challenges

- Blurry Prints: Ensure the image resolution is sufficient for the desired print size. Low-resolution images may result in pixelation or blurriness.

- Inconsistent Adhesion: Adjust the heat press machine pressure to ensure consistent and even pressure across the entire design.

- Ink Smudging: Make sure the ink is fully dried before proceeding with the transfer process. Increase the drying time if needed.

6. Maintenance and Cleaning

- Clean the printer regularly to prevent ink clogs or blockages that can affect print quality.

- Maintain the heat press machine by regularly cleaning and inspecting the heating elements and pressure settings.

Remember, practice and experimentation are key to mastering DTF printing. Monitor and document your settings and outcomes to develop a reliable process for consistent results. Stay up to date with DTF printer manufacturer guidelines and seek support from online communities or forums to learn from others’ experiences. With time and practice, you’ll refine your skills and achieve successful and high-quality DTF prints.

Advantages of DTF Printing

DTF printing offers several advantages over other printing methods, making it a preferred choice for many businesses and individuals. Here are the key benefits of DTF printing:

- Excellent Print Quality: DTF delivers sharp, vibrant prints with intricate details and gradients.

- Durability: DTF prints resist fading, cracking, and peeling, ensuring long-lasting quality.

- Cost-Effectiveness: DTF is economical for small to medium print runs, eliminating setup costs.

- Faster Turnaround: DTF enables quicker production without screen preparation or layering.

- Eco-Friendly: DTF printing reduces waste and consumes less water, promoting sustainability.

- Versatility: DTF can print on various materials, expanding creative possibilities.

DTF printing’s exceptional print quality, durability, cost-effectiveness, faster production times, eco-friendliness, and versatility make it an ideal choice for businesses and individuals. Whether for personalized apparel, promotional products, or customized home decor, DTF printing delivers outstanding results efficiently.

Limitations and Considerations

Consider these factors when assessing the limitations and considerations of DTF printing:

- Scalability: DTF printing may not be as efficient for large print runs due to the time-consuming process of printing, drying, and transferring each design individually.

- Initial Investment: DTF printing requires an upfront investment in equipment, including a suitable printer and heat press machine, which should be factored into the budget.

Key factors to consider when deciding if DTF printing is suitable for specific projects or businesses:

- Print Quantity: DTF printing is ideal for small to medium print runs, while other methods may be more efficient for large volumes.

- Complexity and Color Vibrancy: DTF excels in reproducing intricate designs and vibrant colors on various materials.

- Budget: Evaluate the costs associated with DTF printing, including equipment, ink, and materials, to ensure it aligns with the available resources.

- Turnaround Time: DTF printing offers faster production and shorter lead times compared to certain traditional methods.

- Environmental Considerations: DTF printing is eco-friendly, as it eliminates the need for screen preparation chemicals and reduces waste.

By carefully considering these factors, one can determine if DTF printing is the right choice for their specific needs. It’s important to weigh the advantages and limitations against project requirements and resources for an informed decision.

Conclusion

In conclusion, DTF printing offers a world of creative possibilities and customization. With its versatility, excellent print quality, and cost-effectiveness for small to medium print runs, it has become a favored printing method across various industries. Whether you’re a designer, business owner, or DIY enthusiast, diving into the world of DTF printing can unlock opportunities for unique and personalized creations. Embrace this innovative technology and explore the endless potential of DTF printing.