In recent years, the DTF industry has experienced remarkable growth and advancements, making it a popular choice for fashion designers, brands, and businesses looking for sustainable and high-quality printing solutions. In this blog post, we will explore the numerous benefits of using DTF hot melt powder and gain valuable insights into its applications across various industries. Additionally, we will provide practical tips for maximizing the potential of DTF adhesive powder to achieve outstanding results in your printing endeavors.

What is DTF Hot Melt Powder?

DTF hot melt powder, also known as dtf powder, is a crucial component in the DTF (Direct to Film) printing process. It is a specialized hot melt adhesive powder made of polyester resin, colors, and other additives. This unique powder plays a pivotal role in ensuring the successful transfer of designs onto various fabrics with exceptional adhesion and durability.

The composition of DTF hot melt powder includes polyurethane resin, which is ground into an adhesive powder. This formulation offers outstanding bonding properties when applied using professional heat press machines. The versatility of this powder extends to its application on different types of fabrics, making it an ideal choice for a wide range of printing needs.

Benefits of using DTF Hot Melt Powder

DTF hot melt powder offers a multitude of advantages, making it an indispensable component in the DTF printing process. Let’s explore the remarkable benefits that this hot melt adhesive powder brings to the realm of textile printing.

Provides Vibrant and Durable Prints

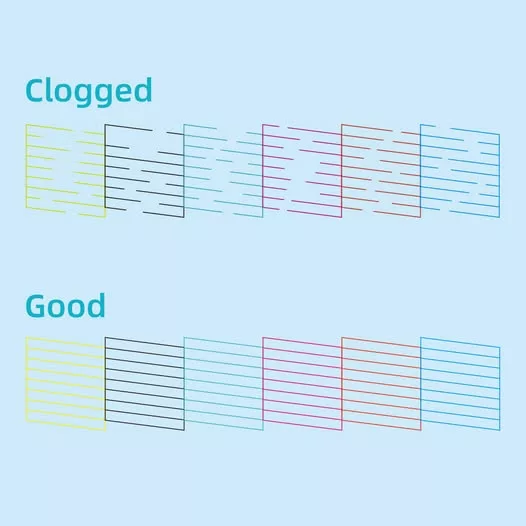

The utilization of DTF hot melt powder ensures that prints exhibit exceptional vibrancy and durability. DTF printing offers numerous benefits in terms of print quality and longevity, with prints considered extremely durable, smooth, elastic, resistant to cracking, and capable of handling heavy use. This is attributed to the adhesive nature of the powder, which binds the ink firmly to the fabric, resulting in long-lasting and visually striking designs.

Enhances Color Saturation and Details

One of the key advantages of transfer powder for DTF is its ability to enhance color saturation and fine details in printed designs. DTF transfers involve printing designs onto a PET film using water-based inks and a special powder binder. The result is impressive quality prints with rich detail and vibrant colors. This enhancement capability allows for intricate details and vibrant colors to be accurately reproduced with exceptional clarity, elevating the overall visual appeal of textile prints.

Cost-Effectiveness

In addition to its aesthetic benefits, hot melt adhesive powder also contributes to cost-effectiveness in textile printing processes. By minimizing ink wastage and ensuring efficient transfer processes, DTF hot melt powder offers economical solutions for textile printing needs. Furthermore, its durability reduces the need for frequent reprints, leading to significant cost savings over time.

Versatility in applications

The application of DTF hot melt powder extends across a wide spectrum of printing needs, showcasing its remarkable versatility and adaptability. This specialized hot melt adhesive powder serves as a crucial component in the DTF (Direct to Film) printing process, offering several advantages over traditional transfer methods.

How to Use DTF Hot Melt Powder

The application process of DTF hot melt powder involves several key steps to ensure precise and consistent results. To begin, it is essential to print designs on a DTF film using water-based inks, creating vibrant and detailed images ready for transfer. Once the design is printed, the next step involves applying an even layer of hot melt adhesive powder over the entire printed area.

Choosing the right DTF Hot Melt Powder

Choosing the right DTF hot melt powder is crucial for achieving the best results in your printing projects. Here are some factors to consider when selecting a DTF hot melt powder:

- Compatibility with your printer: Make sure to choose a DTF hot melt powder that is compatible with your specific printer model. Some powders are designed for specific printer brands or models, so be sure to check the product specifications to ensure compatibility.

- Fabric compatibility: Consider the type of fabric you will be printing on, as not all DTF hot melt powders are suitable for all fabric types. Some powders may work better on polyester fabrics, while others may be designed for cotton or blends. Choose a powder that is appropriate for the fabric you will be using.

- Color intensity and vibrancy: Look for a DTF hot melt powder that provides vibrant and long-lasting colors. Check customer reviews and samples to ensure that the powder delivers the color intensity you desire.

- Washability and durability: Consider the washability and durability of the DTF hot melt powder. A high-quality powder should be able to withstand multiple wash cycles without fading or peeling.

- Ease of use: Choose a DTF hot melt powder that is easy to work with and produces consistent results. Look for powders that are easy to apply and distribute evenly on the transfer paper.

- Cost: Compare prices of different DTF hot melt powders to find a product that fits within your budget while still meeting your quality and performance requirements.

Differences between Black DTF Powders and White DTF powders

When it comes to selecting the right DTFhot melt powder for your printing needs, understanding the differences between black and white powders is crucial. Each variation offers unique properties tailored to specific fabric types, colors, and desired outcomes.

Black DTF Powders

Black dtf powder is specifically engineered for dark-colored garments or fabrics where strong adhesion is critical. It offers exceptional stretch resistance, waterproof properties, and excellent wash resistance—making it suitable for maintaining print integrity even after repeated washing or dry cleaning. The application of black dtf powder extends across a wide spectrum of printing needs, showcasing its remarkable versatility in addressing the challenges associated with transferring designs onto dark fabrics.

White DTF Powders

On the other hand, white dtf powder is formulated with 100% high-purity polyurethane, providing exceptional bonding capabilities while maintaining flexibility. This premium medium adhesive powder serves as a crucial component in achieving vibrant and durable prints on light-colored garments. Its compatibility with delicate fabrics ensures that color vibrancy is preserved without compromising on durability or wash resistance. In addition to its adhesive properties, white dtf powder contributes to enhancing color saturation and fine details in printed designs.

Tips for Achieving Optimal Results With DTF Hot Melt Powder

When it comes to utilizing DTF hot melt powder effectively, there are several essential tips to consider that can significantly impact the quality and durability of your textile prints.

- Use the right type of fabric: Not all fabrics are suitable for DTF printing with hot melt powder. Make sure to use fabrics that have a high polyester content, as they generally provide the best results.

- Ensure proper heat press settings: Different heat press machines have different settings, so make sure to follow the manufacturer’s guidelines for the best results. Typically, a temperature of around 320-330°F and a pressing time of 15-20 seconds is recommended.

- Use the correct amount of hot melt powder: It’s important not to overdo it with the hot melt powder, as too much can cause the design to become blurry or distorted. Follow the recommended guidelines for the amount of powder to use for optimal results.

- Ensure even distribution of the powder: Make sure to spread the hot melt powder evenly across the design, using a squeegee or brush to ensure all areas are covered. This will help to create a smooth and crisp print.

- Allow sufficient cooling time: After pressing the design, allow the fabric to cool down completely before removing the transfer paper. This will help to set the design properly and prevent any smudging or smearing.

- Test different designs and settings: It may take some trial and error to find the perfect settings for your specific design and fabric. Experiment with different designs, temperatures, and pressing times to achieve the best results.

- Consider post-processing techniques: After printing with DTF hot melt powder, consider using post-processing techniques such as heat curing or washing to further enhance the durability and longevity of the design.

Conclusion

In conclusion, DTF hot melt powder serves as an indispensable component in the DTF printing process, playing a crucial role in transferring vibrant and durable designs onto various materials. Composed of polyester resin, colors, and other additives, this printable adhesive powder offers exceptional versatility in applications, making it suitable for cotton, polyester, and even leather materials.

Intrigued by the wonders of DTF technology? Join us in exploring more innovative solutions for your printing endeavors!