The apparel industry has undergone a significant transformation with the advent of garment printing machines. These innovative devices have revolutionized the way we create custom-designed clothing and brought about a new era of personalization.

In this article, we will explore the different types of garment printing machines, their advantages, factors to consider when choosing one, how to use them effectively, and more.

Understanding Garment Printing Machines

Garment printing machines, also known as apparel printing machines, are specialized devices that allow you to print custom designs directly onto garments. They utilize advanced printing technologies to transfer designs, patterns, or images onto various types of fabrics with precision and vibrant color reproduction. These machines have become indispensable in the apparel industry, enabling businesses to offer personalized products and meet the growing demand for unique and customized clothing.

The Advantages of Garment Printing Machines

Garment printing machines offer numerous advantages over traditional printing methods, making them the preferred choice for many businesses and individuals.

Firstly, these machines provide unmatched versatility, allowing you to print intricate designs, detailed graphics, and even photographs on garments. They offer high-quality and durable prints that resist fading, cracking, or peeling over time.

Additionally, garment printing machines offer a quick turnaround time, enabling you to fulfill orders efficiently. Unlike traditional methods like screen printing, which require time-consuming setup and cleanup processes, garment printing machines are ready to use with minimal preparation. This makes them ideal for both small-scale and large-scale production.

Different Types of Garment Printing Machines

There are several types of garment printing machines available in the market, each with its unique features and printing methods. Understanding the differences between them can help you make an informed decision when choosing the right machine for your needs. Let’s explore the most common types:

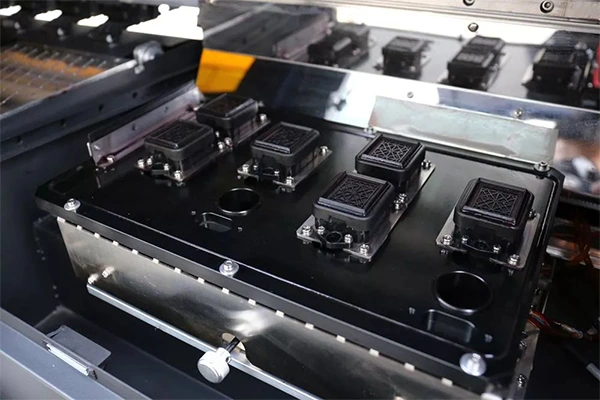

4.1 Direct-to-Garment (DTG) Printing Machines

DTG printing machines are designed to print directly onto garments using inkjet technology. These machines offer exceptional color accuracy and detail, making them suitable for complex designs and multicolor prints. DTG printers are versatile and can handle a wide range of fabric types, including cotton, polyester blends, and even dark-colored garments.

4.2 Screen Printing Machines

Screen printing machines utilize a mesh screen to transfer ink onto the garment. This method is commonly used for bulk printing due to its efficiency and cost-effectiveness. Screen printing machines can produce vibrant and long-lasting prints, especially on light-colored fabrics. However, they may require more setup time and are less suitable for intricate designs or small print runs.

4.3 Heat Transfer Printing Machines

Heat transfer printing machines use heat to transfer designs onto garments. They work by applying heat and pressure to a specialized transfer paper or vinyl, which is then transferred onto the fabric. Heat transfer printing is versatile and can be used on various materials, including cotton, polyester, and spandex. It is commonly used for creating custom t-shirts, sports jerseys, and promotional apparel.

4.4 Sublimation Printing Machines

Sublimation printing machines utilize a heat-sensitive ink that converts from a solid to a gas when heated. This gas permeates the fabric’s fibers, resulting in vivid and long-lasting prints. Sublimation printing is ideal for polyester fabrics and offers excellent color vibrancy and durability. It is commonly used for producing vibrant and full-color designs on sports uniforms, activewear, and polyester-based apparel.

Factors to Consider When Choosing a Garment Printing Machine

When selecting a garment printing machine, it’s essential to consider various factors to ensure it aligns with your business requirements. Here are some key considerations:

5.1 Printing Volume and Speed

Evaluate the printing volume and speed requirements of your business. If you have high production demands, opt for a machine that offers fast printing speeds and can handle large volumes of garments efficiently.

5.2 Print Quality and Resolution

Look for a machine that provides excellent print quality and resolution. Higher resolution ensures sharper details and vibrant colors, resulting in professional-looking prints.

5.3 Versatility and Compatibility

Consider the types of fabrics and garments you intend to print on. Ensure the machine you choose is compatible with a wide range of materials and can handle different garment sizes, shapes, and thicknesses.

5.4 Cost and Maintenance

Evaluate the initial investment cost, ongoing maintenance requirements, and consumables (such as ink and transfer materials) when choosing a garment printing machine. Consider the long-term cost implications to make an informed decision.

How to Use a Garment Printing Machine

Using a garment printing machine effectively involves a series of steps to ensure optimal results. Here’s a step-by-step guide:

6.1 Preparing the Design

Create or import your design using graphic design software or specialized printing software. Ensure the design is properly sized and positioned for the garment.

6.2 Preparing the Garment

Prep the garment by ensuring it is clean, flat, and positioned correctly on the machine’s printing platen. Smooth out any wrinkles or folds to ensure even printing.

6.3 Printing Process

Follow the manufacturer’s instructions to load the garment onto the machine and set up the printing parameters, such as print speed, resolution, and color settings. Initiate the printing process and monitor it closely for any adjustments or troubleshooting.

6.4 Post-Printing Care

Once the printing is complete, carefully remove the garment from the machine and allow it to cool and cure according to the manufacturer’s recommendations. Follow any specific post-printing care instructions, such as heat pressing or washing, to enhance durability.

Tips for Maintaining a Garment Printing Machine

Proper maintenance of your garment printing machine is crucial to ensure its longevity and consistent performance. Here are some essential tips:

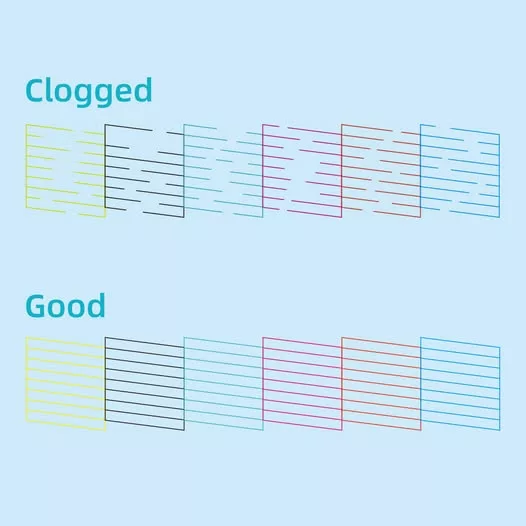

- Regularly clean the print heads, nozzles, and ink lines to prevent clogging and ensure optimal print quality.

- Perform routine maintenance tasks, such as lubricating moving parts and replacing worn-out components, as recommended by the manufacturer.

- Store your machine in a clean and dust-free environment to prevent debris from affecting the printing process.

- Use high-quality and compatible inks, transfer materials, and other consumables to maintain print quality and prevent damage to the machine.

Choosing the Right Garment Printing Machine for Your Business

Selecting the right garment printing machine is crucial for the success of your business. Consider your specific requirements, such as printing volume, budget, and desired print quality, when making a decision. Research different brands and models, read customer reviews, and seek recommendations from industry professionals to make an informed choice.

The Future of Garment Printing Machines

The garment printing industry continues to evolve, driven by advancements in technology and changing consumer demands. As technology progresses, we can expect garment printing machines to become more efficient, versatile, and user-friendly. Innovations like improved print heads, faster printing speeds, and enhanced color accuracy will further propel the industry forward. Additionally, eco-friendly printing solutions and sustainable practices are likely to gain prominence in the future, as the industry strives for more environmentally conscious production methods.

Conclusion

Garment printing machines have transformed the apparel industry, empowering businesses to offer personalized and unique clothing to their customers. With their versatility, efficiency, and high-quality prints, these machines have revolutionized the way we create custom-designed garments. By considering the different types of garment printing machines, key factors for selection, and proper usage and maintenance tips, you can harness the power of these machines to boost your business and meet the demands of the ever-changing market.

FAQs

1. How long does it take to print a garment using a garment printing machine?

The time taken to print a garment depends on various factors such as the complexity of the design, printing method, and machine capabilities. Simple designs can be printed in a matter of minutes, while more intricate and multi-color prints may take longer.

2. Can I print on different types of fabrics using a garment printing machine?

Yes, most garment printing machines are designed to print on various fabric types, including cotton, polyester, blends, and even dark-colored garments. However, it’s essential to check the machine’s specifications and recommended fabric compatibility before printing.

3. What maintenance tasks are required for a garment printing machine?

Regular maintenance tasks for a garment printing machine include cleaning the print heads, nozzles, and ink lines, lubricating moving parts, and replacing worn-out components as needed. Following the manufacturer’s maintenance guidelines is crucial to ensure optimal performance and longevity.

4. Can garment printing machines reproduce vibrant and detailed designs?

Yes, garment printing machines can produce vibrant and detailed designs with excellent color accuracy. However, the quality of the design and the machine’s capabilities, such as resolution and color gamut, can affect the final result. It’s important to use high-resolution designs and choose a machine with advanced printing technologies for the best results.

5. Are garment printing machines suitable for small businesses?

Yes, garment printing machines are suitable for small businesses as well. They offer scalability and flexibility, allowing businesses to start with smaller production volumes and gradually increase their output as the demand grows. Investing in a reliable and cost-effective machine can be a valuable asset for small businesses in the apparel industry.

Please show your support and appreciation by liking this prompt if you have found it truly helpful.