In the early days of DTG printing, the technology was expensive and out of reach for many small businesses. However, thanks to significant advancements, DTG printers have become increasingly accessible and affordable. The evolution of DTG printers has brought the cost down significantly, making them a viable investment for businesses of all sizes.

Understanding the Basics of DTG Printing

Before delving into the world of DTG printing, it is crucial to grasp the basics. So, what exactly is a DTG printer, and how does it differ from traditional printing methods? Unlike traditional printing techniques such as screen printing or heat transfer, DTG (Direct-to-Garment) printing involves printing an image directly onto the fabric of a t-shirt using specialized inkjet technology.

The advantages of DTG printing are twofold – quality and versatility. With DTG printing, you can achieve intricate details and vibrant colors, resulting in high-quality prints that truly stand out. Furthermore, DTG printers allow you to print on a wide range of materials and fabric types, giving you unmatched versatility in your t-shirt designs.

A Direct to Garment (DTG)printer can range in price depending on its size, brand, capability, and whether it is new or used. On average, a DTG printer can cost anywhere from $10,000 to $30,000. Some high-end models could even cost over $50,000.

Evaluating Cost per Shirt Options

When considering purchasing a DTG (Direct-to-Garment) printer, evaluating how much DTG printing costs per shirt is a crucial factor. It’s important to have a clear understanding of the various expenses involved and the overall value each option provides. Here are some key points to consider when assessing cost per shirt options:

Initial Investment

The initial dtg printer price is an important aspect to evaluate. Different printers come with varying features, capabilities, and price ranges. It’s essential to consider your printing needs and budget to find a printer that offers the best value for your investment.

Operational Expenses

Apart from the printer cost, other operational expenses should be accounted for. This includes ink, pretreatment solution, and maintenance supplies. Understanding the ongoing costs for each component and evaluating the average ink coverage per shirt will help in estimating the overall operational expenses per shirt.

Print Quality and Speed

The print quality and speed of a DTG printer can significantly impact the cost per shirt. Faster printers with excellent print quality may allow you to produce more shirts in less time, reducing labor costs and increasing overall output. Assessing the balance between print quality and speed is essential to determine the most cost-effective option.

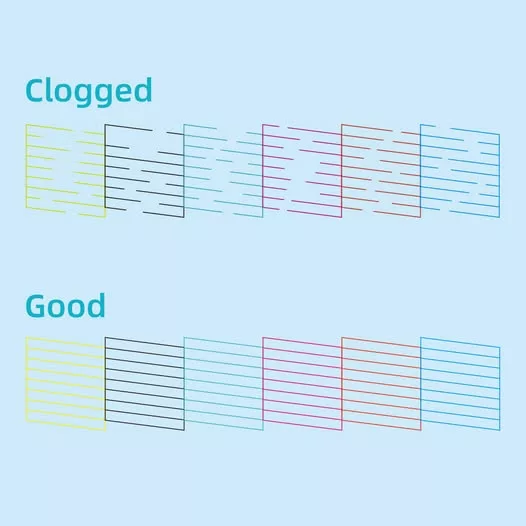

Maintenance and Repairs

Regular printer maintenance and occasional repairs are essential for keeping a DTG printer machine in optimal condition. Evaluating the expected maintenance costs and the availability of after-sales support from the printer manufacturer or supplier is crucial. It’s important to factor in these costs while assessing the overall cost per shirt.

Longevity and Durability

The lifespan of a direct-to-garment printer directly impacts the cost of a shirt. Printers that are built with superior-quality components tend to last longer and require fewer repairs and replacements. Considering the long-term durability and reliability of the machine is essential to calculate the average cost per shirt over its lifespan.

Training and Support

Proper training and support can significantly impact the cost per shirt, especially for those new to DTG printing. Ensuring that comprehensive training is included with the purchase and considering ongoing support options is vital. A well-trained operator can maximize the printer’s efficiency, reducing mistakes and minimizing wastage, thereby lowering the cost per shirt.

Selecting the Right DTG Printer for Your Business

Choosing the right DTG printer is essential for the success of your t-shirt printing business. Several factors come into play when making this decision. Consider the speed, print quality, and reliability of the printer. Look for user-friendly features that streamline the printing process and enhance productivity. Additionally, research popular DTG printer brands and models in the market to make an informed choice.

Budget

The cost of a DTG printer can vary significantly depending on the brand, model, and features. Before making a purchase, it is essential to establish a realistic budget that aligns with your business requirements. Assessing your financial capabilities will allow you to narrow down the available options and focus on printers that fall within your budget range.

Print Volume

Consider the anticipated print volume to determine the printer’s capacity. Some DTG printers are designed for small-scale operations with lower output, while others are built to handle high-volume production. Assessing your business needs will help you select a printer that can efficiently handle the expected workload without compromising on quality.

Print Quality

The quality of prints produced by a DTG printer is a critical factor to consider. Look for printers that offer high-resolution printing capabilities and vibrant colors. Pay attention to factors such as ink droplet size, color gamut, and the number of print heads to ensure the printer can deliver the desired quality, especially if you plan to cater to customers with specific design requirements.

Maintenance and Support

DTG printers require regular maintenance and occasional repairs. Before finalizing your purchase, evaluate the manufacturer’s after-sales support and warranty terms. Ensure that the printer comes with reliable technical support, readily available spare parts, and a comprehensive warranty to minimize any potential downtime.

Ease of Use

Consider the user interface and overall usability of the printer. This includes factors such as software compatibility, intuitive controls, and ease of maintenance tasks like ink cartridge replacement. Investing in a user-friendly DTG printer can save valuable time and reduce the learning curve for operators.

Scalability

As your business grows, you may need to expand your printing capabilities. Look for versatile printers that can accommodate future upgrades or additional features such as modular print heads or an expansion module. This will allow you to adapt the printer to the evolving needs of your business without the need to invest in a completely new system.

Setting Up Your DTG Printing Setup

To optimize the efficiency of your DTG printing setup, you need to have the right equipment and tools. A basic DTG printing setup includes a DTG printer, a heat press machine, and a computer with the necessary software. Additionally, investing in a pretreatment machine and a curing unit can enhance your workflow and ensure consistent results. Don’t forget to optimize your workspace by ensuring proper ventilation and ample room for maneuvering.

Maximizing Profitability with DTG Printing

DTG printing presents opportunities to increase your revenue and maximize profitability. One strategy is to price your DTG printed shirts competitively while considering factors such as material costs, ink consumption, and production time. Additionally, leverage the advantages of DTG printing, such as printing on-demand and offering personalized designs, to attract a wider customer base and increase sales.

Conclusion

With its revolutionary printing capabilities, a DTG printer has the power to transform your t-shirt printing business and unlock your creative potential. By understanding the basics of how much a direct-to-garment printer costs, navigating the affordability aspect, and mastering the art of DTG printing, you can take your business to new heights. Embrace the possibilities that DTG printing offers, unleash your creativity, and let the world experience the exceptional quality and uniqueness of your printed t-shirts.