Product Highlights:

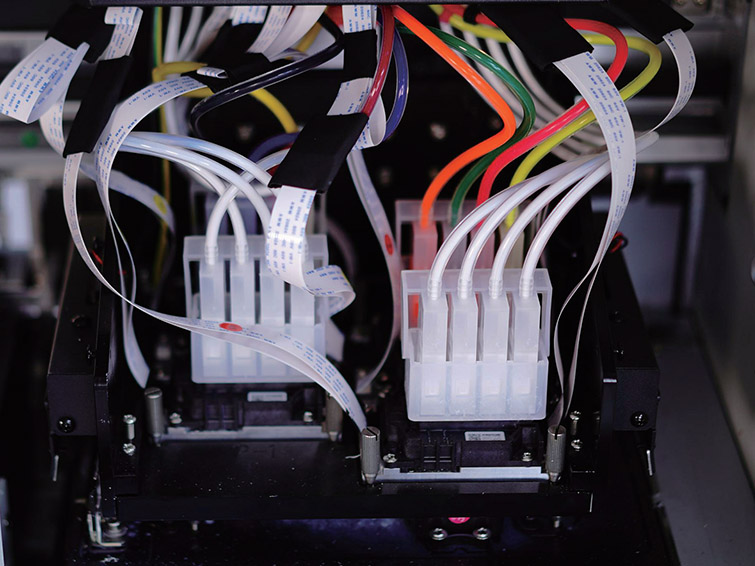

1.4-Head High-Efficiency Printing

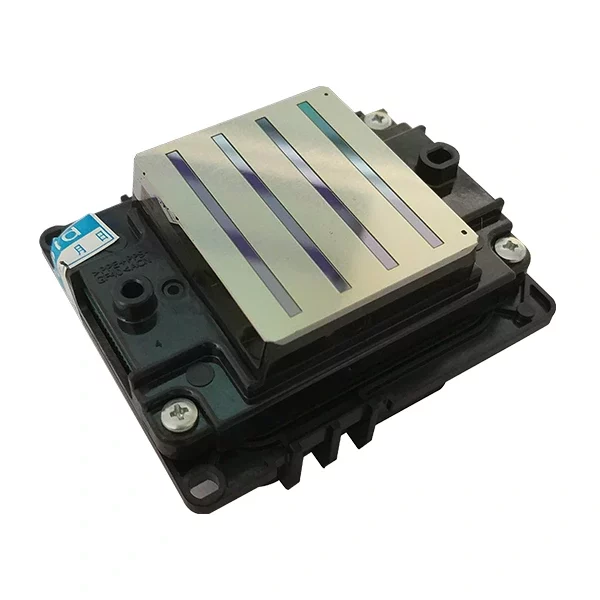

Stable, high-capacity output powered by 4 Epson i3200-A1 printheads for professional DTF production.

2.24-Inch Wide Printing Format

24″ printing width supports large graphics, gang sheets, and multi-layout production in a single run—maximizing material utilization while minimizing waste.

3.Vivid & Durable DTF Transfers

Produces vibrant colors, sharp details, and strong ink adhesion. When paired with Xinflying DTF inks and powders, prints remain washable, stretch-resistant, and long-lasting.

4.Versatile Application Range

Compatible with cotton, polyester, blends, and more—ideal for apparel brands, custom merchandise, promotional products, and print-on-demand businesses.

5.Stable Industrial-Grade Design

Heavy-duty structure with optimized ink delivery ensures smooth operation, consistent output, and reduced downtime during continuous production.

State-of-the-art printer built with advanced technology to offer high precision, speed, and stability to your business success.

The imported mute rail ensures smooth, stable, and noise-free operation. It significantly reduces vibrations, ensuring high precision and longer printer lifespan, even during long production runs.

Equipped with large ink cartridges, this printer supports extended printing sessions, reducing the frequency of ink replacements. It ensures more efficient printing and less downtime.

The user-friendly control panel allows for easy and intuitive operation. With clear labels and one-touch functions, you can control every aspect of the printing process without confusion.

The ink sac system ensures continuous ink supply, preventing ink leakage and clogging. It is designed for high-efficiency, making the printing process more reliable and cost-effective.

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | C604 |

|---|---|

| Printhead and Quantity | 4pcs Epson i3200-A1 |

| Printing Color | CMYK+ CMYK+ W +W |

| Printing Speed |

4PASS:27m²/h 6PASS:18m²/h 8PASS:13m²/h |

| Printing Width | 24" |

| Media Type | DTF Pet Film |

| RIP Software |

Standard with Printfactory,Maintop,RIIN,

PhotoPrint,CADlink for Optional |

|

Temperature/ Humidity |

Temperature:20-30 Celsius Humidity:45-65% |

| Power | 350W |

| Voltage | 220V/110V |

| Operating System |

Windows 11(64bit)/

Windows 10(64bit) |

| Machine Dimension | L1670*W815*H1600mm |

| Package Dimension | L2140*W880*H780mm |

| Net Weight | 180KG |

| Gross Weight | 235KG |

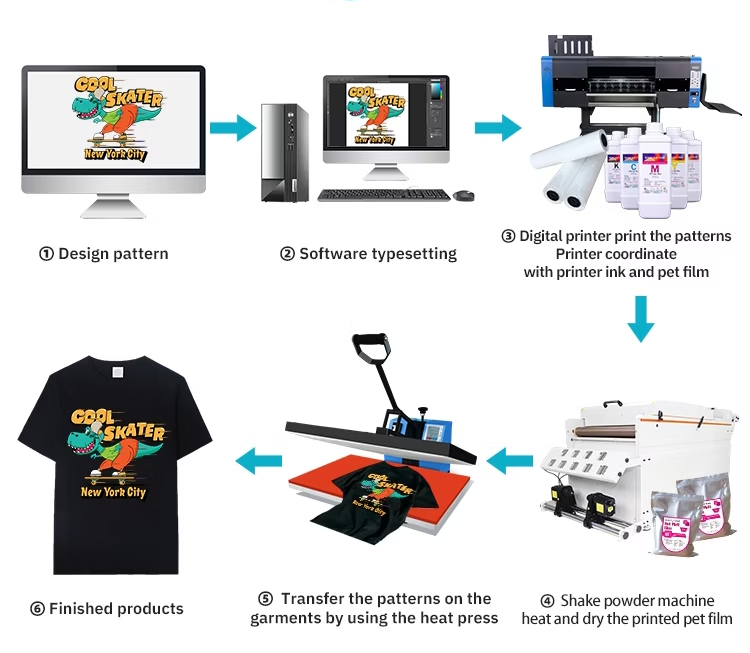

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.