Product Highlights:

1. High-Speed, Wide-Format DTF Production

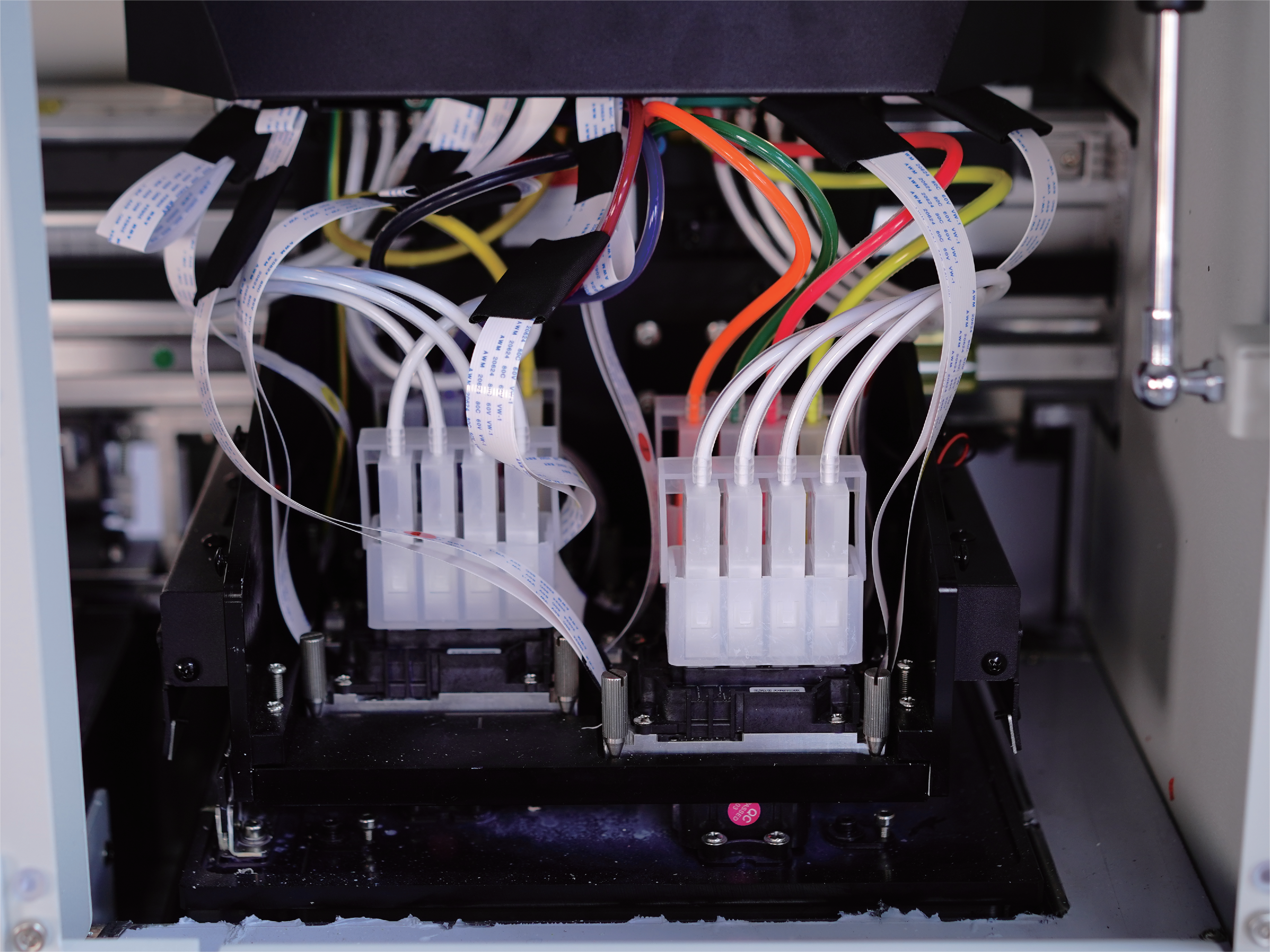

600mm printing width with five Epson i3200-A1 printheads enables fast, high-volume DTF transfer production.

2. Fully Automated Powder & Curing System

Integrated powder shaker, infrared heating, automatic powder recycling, and cooling ensure strong adhesion and consistent transfer quality.

3. Stable Media Handling & Smooth Workflow

Automatic feeding, tension-controlled take-up, adjustable pressure rollers, and extended output platform support continuous production.

4. Energy-Efficient & Operator-Friendly Design

Low power consumption, full thermal insulation, optional smoke purification, and intelligent alerts for powder shortage enhance usability.

The printer is built with an industrial-grade structure and high-precision components, delivering stable performance, fast output, and excellent print quality for continuous DTF production.

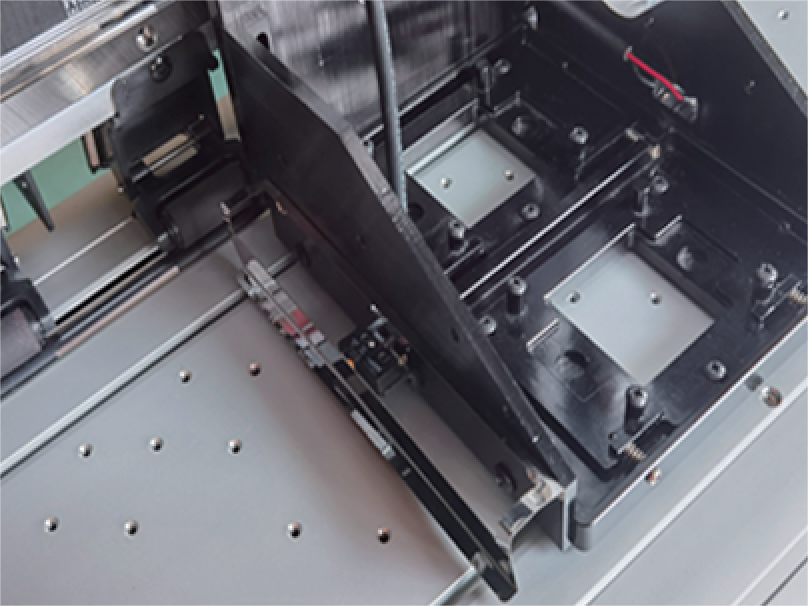

Smart anti-collision sensors detect obstacles in real time, automatically stopping the carriage to protect the printheads and reduce the risk of damage.

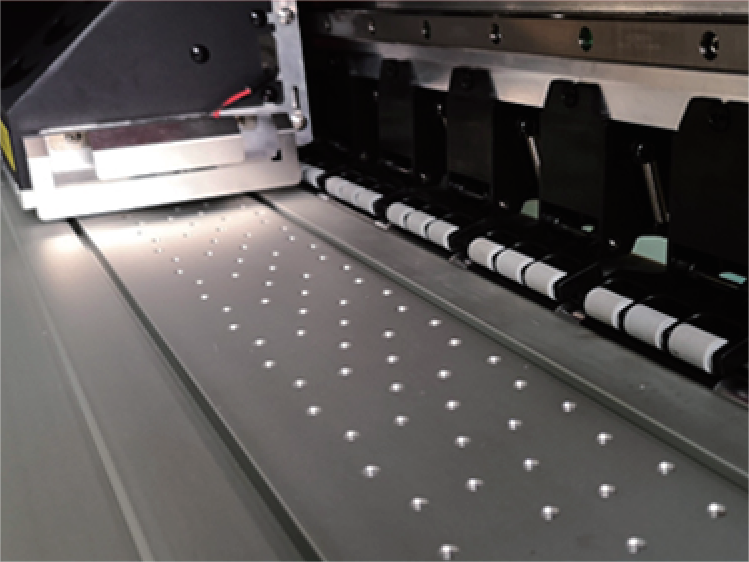

Equipped with a durable silver guide rail that ensures smooth, stable carriage movement, enhancing precision and print consistency even at high speed.

An integrated safety system provides overheat protection, emergency alerts, and intelligent monitoring to ensure safe, reliable operation during long production cycles.

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | C605 |

|---|---|

| Printhead and Quantity | 5PCS I3200-A1 |

| Printing Speed | 6pass: 28m²/h |

| Printing Width | 24" |

| Media Type | DTF Pet Film |

| RIP Software | Standard with Printfactory ,Maintop, RIN, PhotoPrint, CADlink for Optional |

| Temperature | 20-30 °C |

| Humidity | 45-65% |

| Power | 1.6KW |

| Machine Dimension | L1670*W815*H1600mm |

| Package Dimension | L2280*W880*H780 |

| Net Weight | 223KG |

| Gross Weight | 273KG |

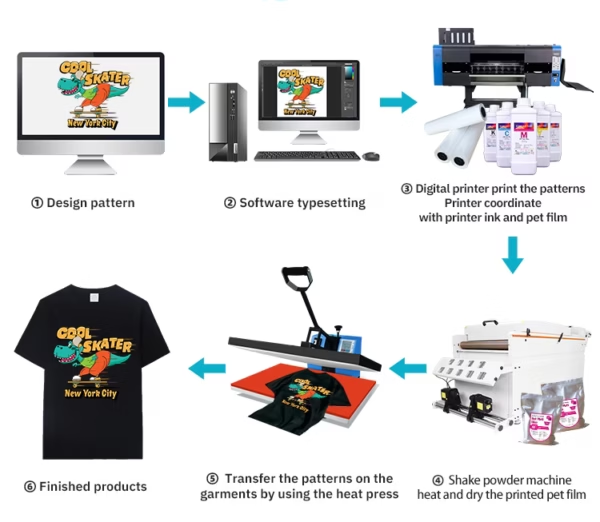

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Q1: Which businesses should consider the C605+H6502?

A: Designed for medium to large businesses, this 5-head DTF printer is ideal for high-volume operations requiring consistent, vibrant prints on various apparel.

Q2: What consumables are required?

A: Uses DTF inks, PET films, and adhesive powders, designed for smooth transfers, efficient ink usage, and consistent print results.

Q3: How is shipping handled?

A: Comes in custom wooden crates with protective foam, suitable for safe international or domestic transport.

Q4: What warranty and technical support are available?

A: Includes a 1-year warranty and lifetime technical support, assisting with installation, maintenance, and troubleshooting.

Q5: What fabrics can be printed on?

A: Supports cotton, polyester, and blended fabrics, delivering long-lasting, vibrant prints for custom apparel production.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.