Product Highlights:

1.Wide-Format DTF Printing Capability

Large printing width supports oversized graphics, gang sheets, and batch production—ideal for bulk DTF orders and efficient material usage.

2.Broad Fabric Compatibility

Suitable for nylon, chemical fiber, cotton, leather, and more, delivering stable adhesion and consistent print quality across different materials.

3.High-Quality DTF Output

Ensures rich color performance, clear details, and strong ink bonding. When used with Xinflying DTF ink and powder, prints remain durable and washable.

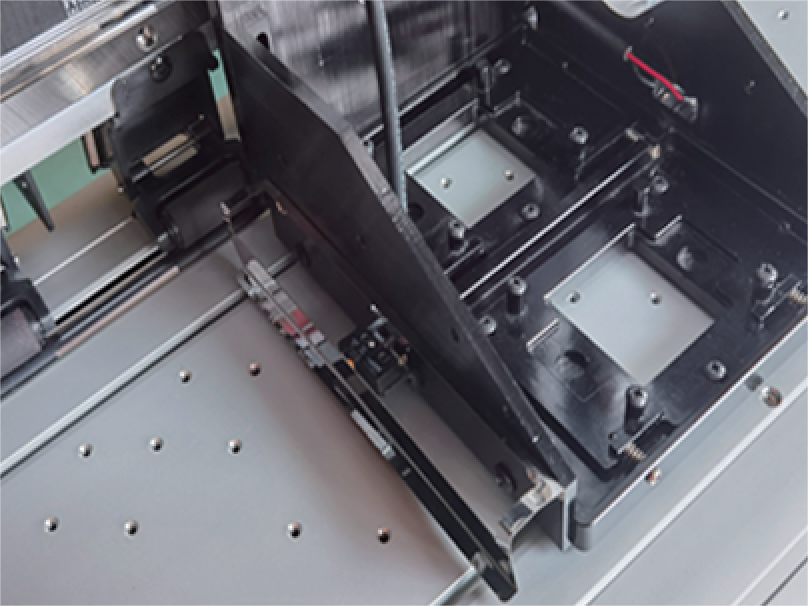

4.Industrial-Grade Structure

Solid machine construction combined with a stable ink delivery system enables smooth operation and reliable performance for long-term production.

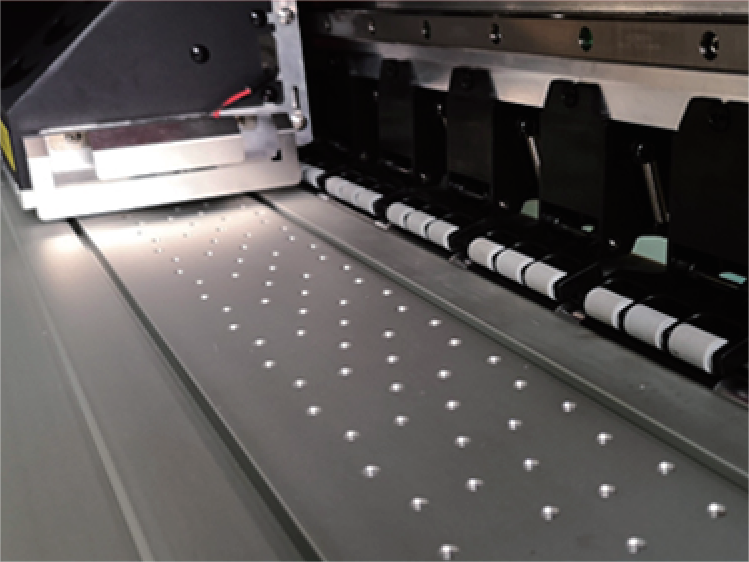

Equipped with a precision mute guide rail, the DTF printer runs with exceptional stability and low noise. It ensures smooth carriage movement, reduced vibration, and high-precision output—ideal for professional direct to film printing environments.

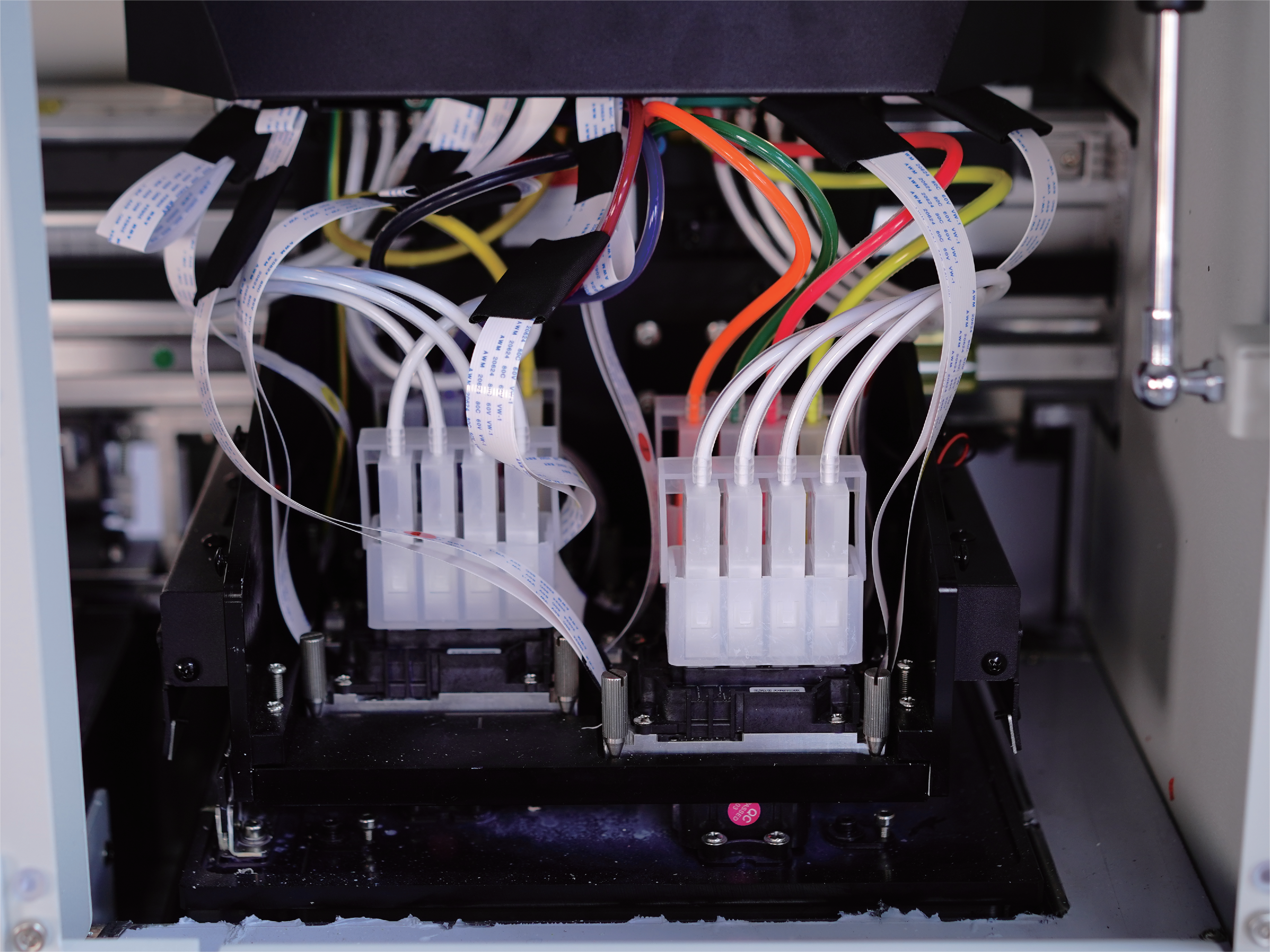

The large-capacity ink system enables longer production cycles for dtf printers, ensuring consistent ink flow. Designed for business-level output, it minimizes interruptions and supports continuous T-shirt printing with stable color performance.

Powered by a high-performance Leadshine motor, the printer delivers accurate motion control and improved durability. This industrial-grade component enhances printing speed, precision, and long-term operational reliability.

A simplified control panel allows operators to run the dtf printer with ease. From status monitoring to settings adjustment, the user-friendly interface improves workflow efficiency for DTF printer for shirts production.

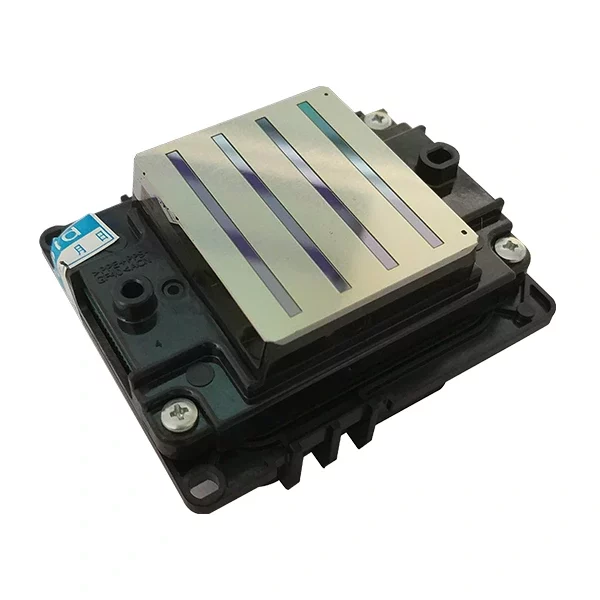

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | C804 |

|---|---|

| Printhead and Quantity | 4PCS I3200-A1 |

| Printing Speed | 4Pass:25m²/h 6Pass:18m²/h |

| Printing Width | 32" |

| Media Type | DTF Pet Film |

| RIP Software | Standard with Printfactory,Maintop, RIN,PhotoPrint,CAD link for Optional |

| Temperature | 20-30 °C |

| Humidity | 45-65% |

| Power | 1.1KW |

| Machine Dimension | L1950*W820*H1680mm |

| Package Dimension | L2135*W875*H760mm |

| Net Weight | 150KG |

| Gross Weight | 230KG |

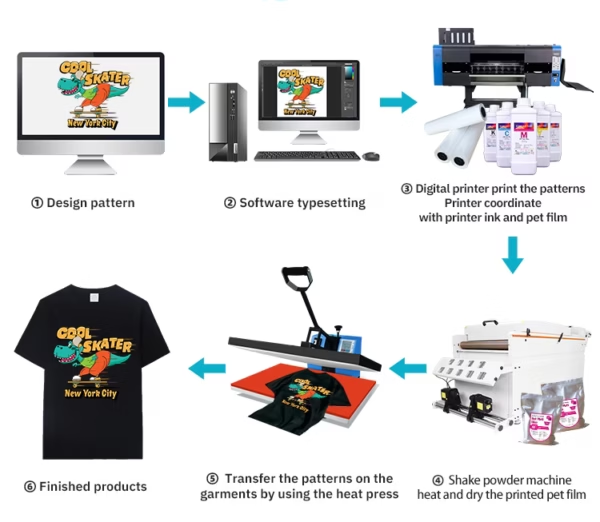

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Q1: Who is this printer suitable for?

A: Ideal for industrial-scaleprinting businesses, providing 4 printheads for high-quality DTF printing on a variety of textile products.

Q2: What consumables does it use?

A: Uses DTF inks, PET transfer films, and adhesive powders, optimized for efficient operation and consistent, vibrant results.

Q3: How is the printer shipped?

A: Delivered in reinforced wooden crates with protective foam, ensuring safe transportation for international and domestic shipping.

Q4: What warranty and support are available?

A: Offers a 1-year warranty and lifetime technical support, assisting with setup, troubleshooting, and ongoing maintenance.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.