Product Highlights:

1. Stable & Precise Garment Printing Design

Built with a professional control system and imported linear guides to ensure smooth movement and accurate garment printing.

2. High-Quality Color & Detail Output

Equipped with dual Epson i3200-A1 / i3200-A1HD printheads, delivering vivid colors, fine details, and consistent print quality.

3. Easy Operation for Daily Production

7-inch touch screen, one-button ink priming and cleaning, and automatic platen height adjustment simplify operation and maintenance.

4. Reliable Protection & Ink Management

Printhead anti-collision protection, low-ink voice alerts, and intelligent positive-pressure ink circulation ensure stable and safe production.

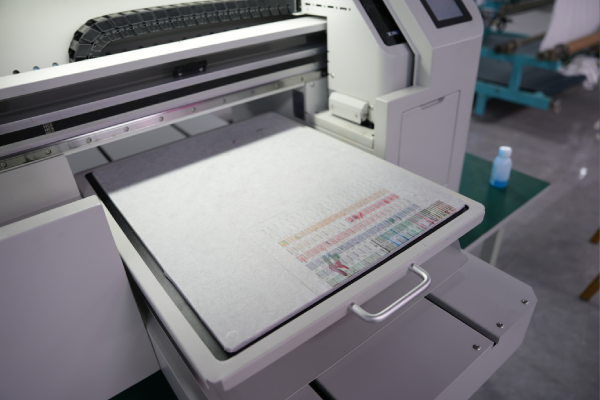

The user-friendly panel can be used to control ink droplet accuracy and speed. With this, T-shirts can be tiled and printed on the platform with no hassle.

This image shows the DTG printer bed, designed for easy garment loading, ensuring precise and high-quality printing on textiles.

The ink supply system features multiple color cartridges, providing consistent color accuracy for vibrant prints on various fabrics.

It features a magnetic white ink mixing system that avoids and alleviates the precipitation of coloring materials in white ink, which prevent ink clogging.

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | DTG-10-2I32A1 |

|---|---|

| Print Head | 2pcs Epson i3200-A1 |

| Spray Hole Columns | 8 |

| Ink Type | Environmentally friendly paint ink |

| Print Format | 400*500(mm) |

| Printing Efficiency | 6PASS A4 Size:45 pcs/h;A3 Size: 23 pcs/h |

| Ink Color Quantity | CMYK+W;K,C,M,Y,R,G,B,O,W (Option) |

| Print Thickness | Max 25(mm) |

| RIP Software | Hosonsoft Rip |

| Temperature / Humidity | 20-28 Celsius/35%-65% Rh |

| Power Supply/Voltage | 220V/110V ; 5A/10A ; 50HZ/60HZ |

| Net Weight | 108KG |

| Gross Weight | 120KG |

| Dimension | L1100*W1080*H580mm |

| Package Dimension | L1280*W1260*H760mm |

Create or upload your artwork in the design software.

Spray the pretreatment solution evenly onto the garment for better color brightness and adhesion.

Place the garment flat on the platen and let the DTG printer print the design directly onto the fabric.

Use a heat press or dryer to cure the ink and ensure durability.

The garment is ready with a vibrant, long-lasting print.

Q1: What type of business is the XF-DTG-10 suitable for?

A: The XF-DTG-10 is designed for small to medium DTG printing businesses, startups, print shops, and on-demand apparel brands. Its single-station structure makes it ideal for custom T-shirt printing, small batch production, and personalized garment orders.

Q2: Which printhead does the XF-DTG-10 use?

A: This DTG printer is equipped with an Epson I3200-A1 printhead, offering high resolution, stable ink output, and excellent color accuracy for detailed and consistent T-shirt printing.

Q3: What types of garments and inks can be used?

A: The XF-DTG-10 supports professional DTG pigment inks and is suitable for cotton and high-cotton blended fabrics. With proper pre-treatment, it can print on both light and dark garments with durable wash resistance.

Q4: Is the XF-DTG-10 easy to operate for beginners?

A: Yes. The printer features a smart touchscreen control panel and a simplified operating workflow, making it easy for beginners to learn and operate. Basic setup guidance and technical support are provided.

Q5: Do you offer worldwide shipping and after-sales support?

A: Yes, we provide global shipping via air or sea freight. Each machine is securely packed, and we offer ongoing technical support, maintenance guidance, and spare parts supply.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.