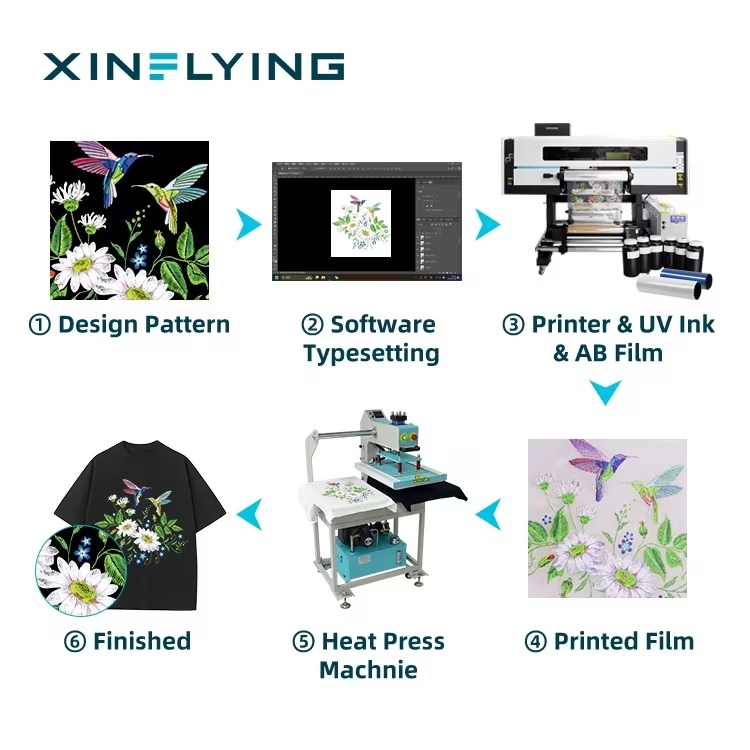

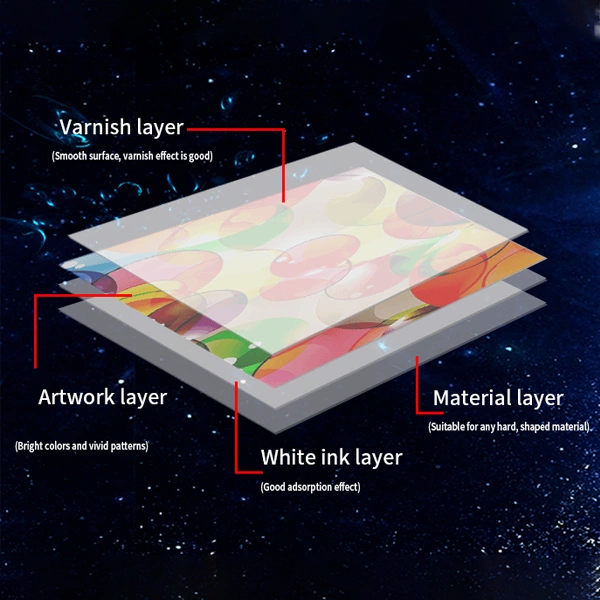

One-stop with Glue & Varnish

Equipped to perform one-stop working process, including printing, CMYK + white ink, gluing, and varnishing function at the same time. After that, you only need to place it on the product surface and slowly peel it off.

PrecisionCore Technology

Features high precision and high density with 600 dpi/2 rows of nozzles. This contributes to its compactness, speed, and image quality. Also, it comes with unique MEMS nozzles and an ink flow path that ensures the ink droplets are placed accurately.

Luminating Machine

Suitable for label printing business as the UV DTF printer comes with a laminator that helps in transferring the full-color patterns without hassle, as well as protecting the label from easily damage.