UV DTF printing is a cutting-edge printing technology that has revolutionized the printing industry. It stands for Ultraviolet Direct to Film printing and is a process that involves transferring digital designs onto a wide range of materials using UV-curable ink and a special film. In this article, we will explore the ins and outs of UV DTF printing, how it works, and its benefits compared to traditional printing methods.

What Is UV DTF Printing?

UV DTF printing is a form of direct-to-substrate printing that utilizes UV-curable ink to create high-quality prints on various materials. Unlike traditional printing methods that rely on heat transfer or sublimation, UV DTF printing directly transfers the design onto the material, resulting in vibrant and detailed prints.

What Do I Need for UV DTF Printing?

To get started with UV DTF printing, you will need a UV DTF printer, UV-curable ink, a special film, and the material you want to transfer the design onto. The UV DTF machine is crucial for the process as it is specifically designed to handle UV-curable inks and accurately transfer the design onto the material.

How Does a UV DTF Work?

UV DTF (Direct to Film) printing is a relatively new technology that allows for high-quality printing on various materials such as textiles, plastics, and more. Here is how a UV DTF printer works step by step:

- Artwork Design: The process starts with creating or selecting the artwork that you want to print on the material. This can be done using graphic design software.

- Printing on A Film: The next step involves printing the artwork onto a special A film using a UV DTF printer. The printer uses UV-curable inks that are specially formulated for this printing process.

- Covering B Film: Once the artwork is printed on the film, it needs to use a laminator to adhere the A film to the B film. Then, you may need to use a cutting machine or scissors to cut out the design you want.

- Application to Material: Then removed the A film and placed the design on the material that you want to print on, such as a ceramic mug or a plastic surface. Press the design using the finger to let it firmly adhere the product and then peel off the B film.

What Materials Can Be Transferred On?

UV DTF printing is versatile and can be used to transfer designs onto a variety of materials. Some of the most common materials include:

Glass

Glass is a popular choice for UV DTF printing due to its smooth surface and ability to showcase detailed designs with vibrant colors. From windows to glassware, UV DTF printing can add a personalized touch to any glass surface.

Wood

Wood is another material that can benefit from UV DTF transfer printer. Whether it’s custom signage, furniture, or wooden boxes, UV DTF printing can bring intricate designs to life on wood surfaces.

Metal

Metal surfaces, such as aluminum or stainless steel, are also compatible with UV DTF printing. This allows for the creation of durable and long-lasting prints on metal objects like signs, nameplates, or personalized gifts.

Plastic

Plastic materials, such as acrylic or PVC, can be transformed with UV DTF printing. Whether it’s creating custom displays, promotional items, or product labels, UV DTF printing can enhance the visual appeal of plastic surfaces.

Ceramics

Ceramic surfaces, like mugs, tiles, or plates, can be decorated with UV DTF printing. This allows for the customization of ceramic items with intricate designs and vibrant colors that can withstand everyday use.

Benefits of UV DTF Printing

There are several benefits to using UV DTF printing for your printing needs:

High-quality printing on various materials

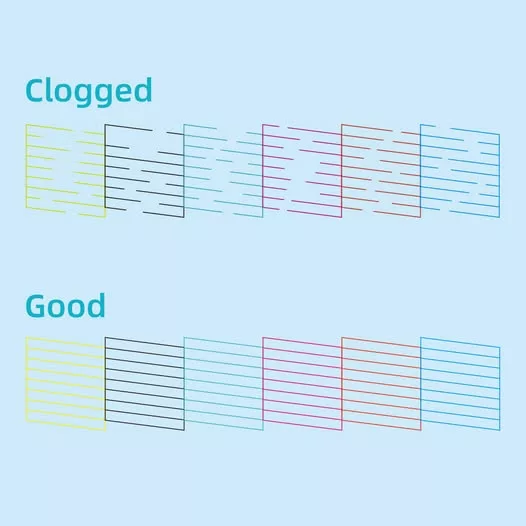

UV DTF printing offers exceptional print quality with sharp details and vibrant colors. The direct transfer process ensures that the design is accurately replicated on a wide range of materials, making it ideal for creating detailed graphics and images.

Durable and long-lasting prints

UV-curable inks used in UV DTF printing are known for their durability and resistance to fading, scratching, and water damage. This ensures that the prints produced through UV DTF printing are long-lasting and can withstand wear and tear.

Cost-effective solution for small and large-scale projects

UV DTF printing is a cost-effective solution for both small and large-scale printing projects. It eliminates the need for additional materials or processes, reducing overall production costs while maintaining high-quality results. Additionally, the quick turnaround time of UV DTF printing makes it an efficient option for meeting tight deadlines.

UV DTF vs. DTF, What’s the Difference?

When comparing UV DTF (Direct to Film) printing to traditional DTF printing, there are notable differences that set them apart in terms of quality, durability, and versatility.

UV DTF Printing

- UV DTF printing utilizes UV-curable ink, which offers vibrant colors and high durability.

- The UV ink used in UV DTF printing is instantly cured with UV light, resulting in fast drying prints.

- UV DTF printing allows for high-quality prints on a wide range of materials, including glass, wood, metal, plastic, and ceramics.

- The prints produced through UV DTF are scratch-resistant and fade-resistant, ensuring long-lasting and vibrant designs.

Traditional DTF Printing

- Traditional DTF printing involves transferring ink from a film onto the desired material using heat and pressure.

- The prints created through traditional DTF may not have the same level of vibrancy and durability as UV DTF prints.

- Traditional DTF printing is typically limited to certain materials and may not be suitable for as wide a range of applications as UV DTF printing.

In summary, UV DTF printing offers superior print quality, durability, and versatility compared to DTF printing. The UV-curable ink used in UV DTF provides vibrant colors and long-lasting prints on various materials, making it a preferred choice for many printing projects.

Conclusion

In conclusion, UV DTF printing is a cutting-edge printing technology that offers high-quality, durable, and cost-effective printing solutions for a wide range of materials. With its ability to transfer vibrant designs onto glass, wood, metal, plastic, and ceramics, UV DTF printing is a versatile option for creating personalized and visually appealing prints. Whether you’re looking to print custom signage, promotional items, or decorative pieces, UV DTF printing can help bring your vision to life with exceptional detail and precision.