Source: https://www.indiamart.com

DTF printing has become increasingly popular in the garment and textile printing industry as it offers several advantages over traditional sublimation printing. DTF printing allows for printing on a wider range of fabrics and produces more vibrant and detailed prints. These benefits make it an appealing option for businesses that aim to expand their product offerings and increase production efficiency.

This article will examine the advantages of using a DTF printer for business printing needs, which include the ability to print on both natural and synthetic fabrics, faster turnaround times, and more efficient production. Additionally, the article will discuss the essential factors to consider when selecting a DTF printer, such as print quality, speed and production capacity, ink and consumables, compatibility, and support and warranty. Understanding the benefits and considerations of DTF printing can help businesses make informed decisions for their printing needs.

What is DTF printing?

Source: https://www.brildor.com

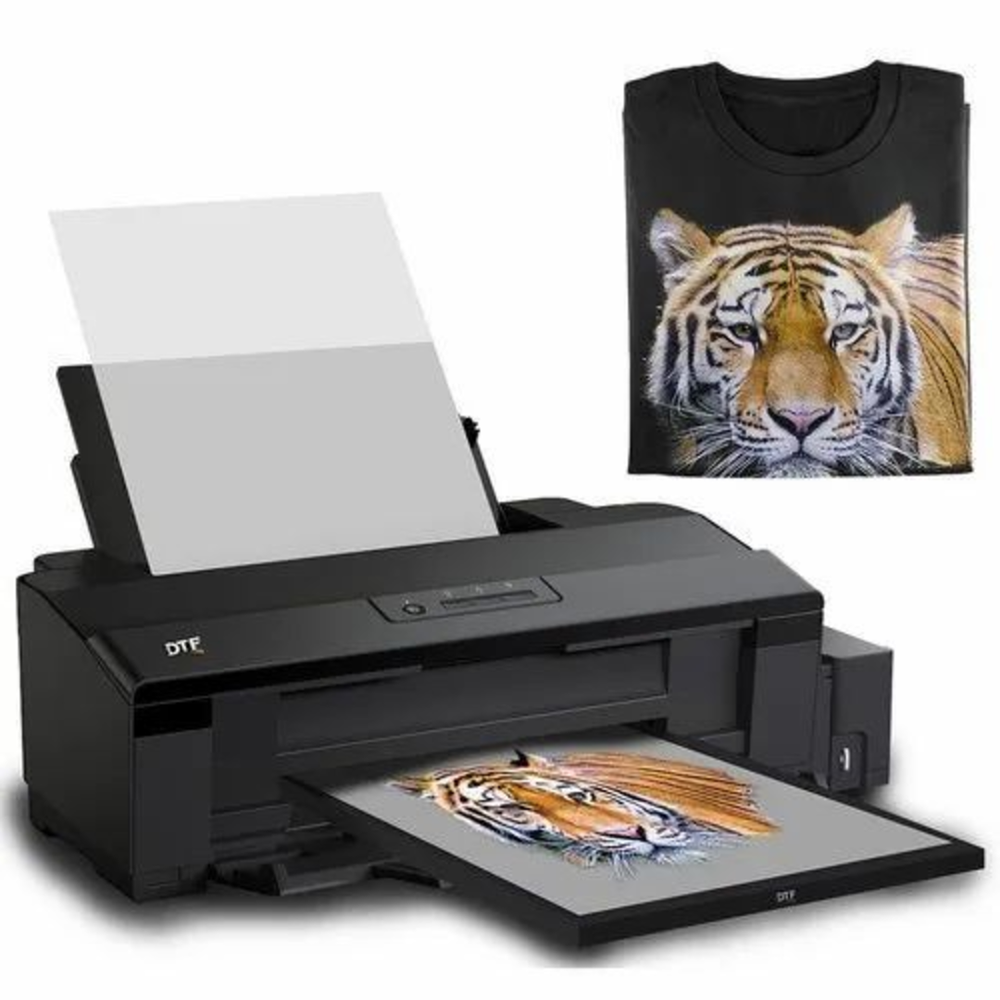

DTF (Direct-to-Film) printing is a relatively new technology that has gained popularity in the garment and textile printing industry. It is a digital printing method that allows for printing designs and patterns onto fabrics using a special type of transfer film.

How the DTF Printing Works

In traditional sublimation printing, the design is first printed on a transfer paper using sublimation ink. The transfer paper is then applied to a specific type of substrate, such as polyester or other synthetic fabrics, using a heat press. The heat and pressure cause the ink to sublimate and bond with the substrate, resulting in a permanent and durable print.

DTF printing, on the other hand, uses a special type of DTF film that is coated with a unique adhesive layer and DTF powder. The design is directly printed onto the transfer film using a DTF printer and special DTF ink. The transfer film is then applied to the fabric using a heat press, where the adhesive layer melts and adheres to the fabric. The film is then peeled off, leaving the design on the fabric.

Overall, DTF printing is a promising technology that offers several advantages over traditional sublimation printing. As the technology continues to evolve and improve, it may become a more popular and widely used printing method in the textile and garment industry.

Cost-Effectiveness of DTF Printing

Source: https://www.dreamstime.com

DTF printing is a relatively new technology that is gaining popularity in the garment and textile printing industry. While DTF printing may require a higher initial investment in equipment and materials compared to traditional sublimation printing, it can offer significant cost savings in the long run.

One of the biggest cost-saving advantages of DTF printing is its ability to print on a wider range of fabrics, including natural fibers and blends. This allows businesses to expand their product offerings and cater to a wider range of customers without having to invest in additional equipment or materials.

DTF printing can also be more cost-effective in terms of ink usage. Because the ink is directly applied to the transfer film, there is less waste compared to traditional sublimation printing, where excess ink can be left on the transfer paper and not transferred to the substrate.

Additionally, DTF printing can offer faster turnaround times and more efficient production. The process of printing, cutting, and weeding the transfer film is more streamlined and can be done in-house, reducing the need for outsourcing and additional labor costs.

Durability of DTF Prints

Source: https://www.pinterest.com.au

However, recent advancements in DTF printing technology have resulted in more durable prints that can withstand multiple washings and wear over time. The durability of DTF prints is largely dependent on the quality of the transfer film and ink used, as well as proper post-printing techniques.

To ensure the longevity of DTF prints, it is important to use high-quality transfer film and ink that are designed specifically for DTF printing. Proper heat and pressure settings during the transfer process, as well as proper post-printing techniques such as washing and drying the garment according to DTF printer manufacturer recommendations, can also help to increase the durability of DTF prints.

Overall, while the durability of DTF prints may have been a concern in the past, advancements in technology and proper printing techniques can result in prints that are just as durable as those created through traditional sublimation printing methods.

DTF Printing and Customization

Source: https://atlantavinylstore.com

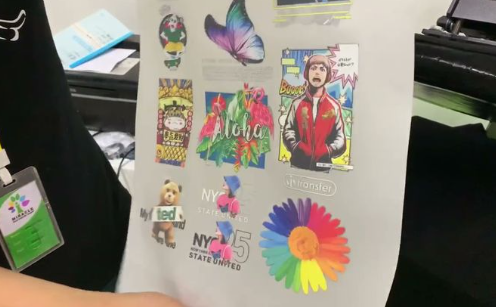

DTF printing can be used to create custom designs, logos, and patterns on various fabric types, including natural fibers and blends. This allows businesses to offer a wider range of customized products, such as t-shirts, hoodies, and other apparel items, to their customers.

The ability to offer customization also allows businesses to cater to specific niches and target markets, such as sports teams, schools, and other organizations. With DTF printing, businesses can create unique and personalized products that reflect the branding and messaging of their clients.

Additionally, DTF printing can offer faster turnaround times and more efficient production for customized products. The process of printing, cutting, and weeding the transfer film is more streamlined and can be done in-house, reducing the need for outsourcing and additional labor costs.

Overall, DTF printing offers businesses and individuals the ability to create customized and personalized products with high-quality and detailed prints. With its ability to print on a wide range of fabrics and offer efficient production and turnaround times, DTF printing is a promising technology for businesses looking to expand their product offerings and cater to specific niches and markets.

Factors to Consider When Purchasing a DTF Printer

Source: https://www.flaticon.com

Purchasing a DTF printer can be a significant investment for businesses looking to expand their product offerings and increase production efficiency. To ensure that you choose the right DTF printer for your specific needs, there are several factors to consider.

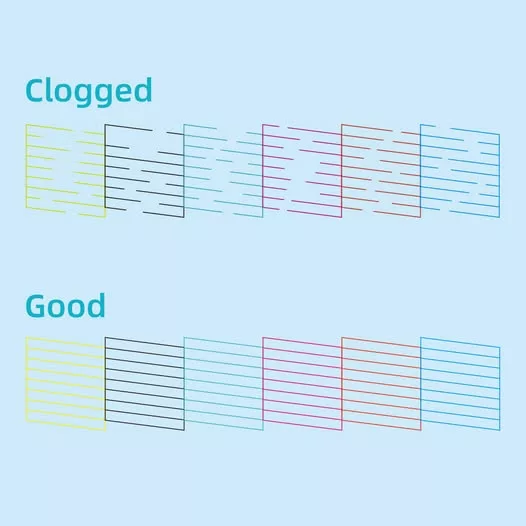

Print Quality

The print quality of a DTF printer is a crucial factor to consider when purchasing. Look for a printer that offers high-resolution printing and accurate color reproduction. You may also want to consider a printer that offers the ability to print white ink, which can enhance the vibrancy of colors on dark fabrics.

Speed and Production Capacity

The speed and production capacity of a DTF printer are important factors to consider, especially if you plan to use the printer for high-volume production. Look for a printer that offers fast printing speeds and a large printing bed to maximize production efficiency.

Ink and Consumables

The quality and cost of ink and consumables is another important factor to consider when purchasing a DTF printer. Look for a printer that uses high-quality ink and consumables that are specifically designed for DTF printing. You may also want to consider the cost and availability of replacement ink and consumables, as well as the ease of changing them out.

Compatibility

When purchasing a DTF printer, it’s important to consider its compatibility with your existing equipment and software. Look for a printer that is compatible with your current computer operating system and design software, as well as any heat presses or other equipment you may already have.

Support and Warranty

Finally, consider the support and warranty offered by the manufacturer. Look for a manufacturer that offers comprehensive customer support and a warranty that covers any potential issues or defects with the printer.

In summary, when purchasing a DTF printer, it’s important to consider factors such as print quality, speed and production capacity, ink and consumables, compatibility, and support and warranty. By carefully consider

Conclusion

Source: https://www.pinterest.com.au

In conclusion, DTF printing is a promising technology that offers several advantages over traditional sublimation printing, making it an attractive option for businesses looking to expand their product offerings and increase production efficiency.

DTF printing allows for printing on a wider range of fabrics and produces more vibrant and detailed prints, resulting in high-quality and unique products. Additionally, DTF printing offers faster turnaround times and more efficient production, which can help businesses save time and money.

When choosing a DTF printer, it’s important to consider factors such as print quality, speed and production capacity, ink and consumables, compatibility, and support and warranty. By understanding the benefits and considerations of DTF printing, businesses can make informed decisions and choose a printer that best fits their specific needs.

With its ability to offer customization options and efficient production capabilities, DTF printing is a promising technology for businesses in the garment and textile printing industry.