In today’s fast-paced world, technological advancements have become a driving force behind many industries. The printing industry is no exception to this trend, constantly evolving to meet the needs and demands of modern consumers. One of the latest innovations in printing technology is the Powerless DTF printer. In this comprehensive guide, we will explore what a powerless DTF printer is, how it revolutionizes the printing industry, and why it may be the future of printing.

What is Powerless DTF Printing Technology

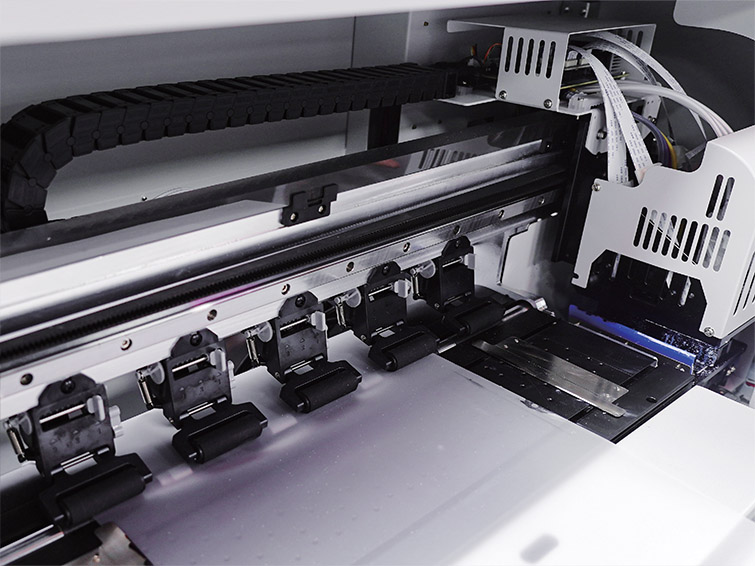

To fully comprehend the power of a powerless DTF printer or no powder dtf printer, it is crucial to explore the basics of DTF printing. DTF stands for “Direct To Film” printing, a technique that involves transferring ink from a film onto a printable surface. Unlike traditional printing methods that require excessive powder application to produce high-quality prints, the powerless DTF printer eliminates the need for this step altogether.

Unveiling the power of powderless printing, a key feature of the powerless DTF printer, is the elimination of excess powder. Traditional DTF printers rely on the use of powder to enhance color vibrancy, clarity, and durability of prints. However, this process often leads to a messy and time-consuming experience for both the printer and the recipient of the printed product.

Powderless DTF Printing Process: Step-by-Step Guide

The powderless DTF printing process is simple yet revolutionary. Here is a step-by-step guide to help you understand the process:

- Design Preparation: Begin by designing your artwork using graphic design software. Ensure that the design corresponds to the desired dimensions and specifications of the printable surface.

- Film Printing: Once the design is ready, print it onto a transparent film using a compatible printer. This film will later serve as the transfer medium.

- Film Transfer: With the printed film in hand, position it meticulously onto the printable surface. Apply heat and pressure using a heat press machine to enable the ink transfer from the film to the surface.

- Peel and Reveal: After the transfer process is complete, carefully peel off the film to reveal the vibrant and high-quality print on the surface. Voila! Your print is now ready.

Advantages of Powerless DTF Printers

Now that we have delved into the process of powerless DTF printing, it’s time to explore the numerous advantages associated with this cutting-edge technology.

- No need for excessive powder application: With a powerless DTF printer, the cumbersome and messy process of excessive powder application becomes a thing of the past. This not only saves time but also eliminates the risk of powder residue affecting the final print quality.

- Enhanced color vibrancy and clarity: The elimination of powder application allows for a clearer transfer of ink, resulting in enhanced color vibrancy and clarity. Your designs will truly come to life with a powerless DTF printer.

- Higher printing speed: The efficiency of powerless DTF printers enables a higher printing speed compared to traditional DTF printers. This means you can produce a larger volume of prints in a shorter amount of time, increasing productivity and profitability.

- Lower production costs: By eliminating the need for excessive powder application, powerless DTF printers significantly reduce production costs. This cost-saving feature makes it an attractive option for businesses looking to maximize their profit margins.

- Increased durability of prints: Another notable advantage of powerless DTF printers is the increased durability of prints. The absence of excessive powder ensures that the ink adheres more strongly to the printable surface, resulting in longer-lasting and more resilient prints.

Applications of Powerless DTF Printing

Powerless DTF printing has a wide range of applications across various industries. Let’s explore some of the most prominent ones:

Custom Apparel and Fashion Industry

From personalized t-shirts to custom-designed fabrics, powerless DTF printing offers endless possibilities for the apparel and fashion industry. Designers and clothing entrepreneurs can bring their creative visions to life with vibrant and durable prints.

Home Décor and Interior Design

Powerless DTF printing opens up new avenues for interior designers and home décor enthusiasts. Custom-printed wallpapers, fabric patterns, and even bespoke furniture upholstery can be effortlessly created with this innovative technology.

Promotional and Branding Materials

Businesses and marketing professionals can take their promotional and branding efforts to the next level with powerless DTF printing. From custom-printed promotional merchandise to eye-catching signage and banners, the scope for creative advertising is immense.

Personalized Gifts and Accessories

Whether it’s a custom-printed mug, a personalized phone case, or even a unique piece of jewelry, powerless DTF printing allows individuals to unleash their creativity and create heartfelt and memorable gifts and accessories.

DTF Printer vs. DTG Printer vs. Powerless DTF Printer

When it comes to printing technologies, there are various options available, each with its own set of advantages and disadvantages. In this section, we will compare the traditional DTF printer, the popular DTG (Direct-to-Garment) printer, and the innovative Powerless DTF printer.

How do They Differ?

| Printing Technology | DTF Printer | DTG Printer | Powerless DTF Printer |

| Printing Method | Transfer using excessive powder application | Direct-to-garment inkjet printing | Transfer without excessive powder application |

| Color Output | Vibrant and sharp prints | Excellent detail and color accuracy | Enhanced color vibrancy |

| Material Compatibility | Wide variety of surfaces including textiles, ceramics, etc. | Suitable for most garment materials | Suitable for most flat surfaces |

| Printing Speed | Average speed, additional time required for powder application | Average speed | Higher speeds due to elimination of powder application |

| Limitations | Limited to flat surfaces and specific materials | Struggles with vibrant prints on dark fabrics | Limited to flat surfaces |

| Initial Investment | Moderate cost | Moderate cost | May require an initial investment |

| Usability | Requires powder handling and cleanup | User-friendly, suitable for small print runs | User-friendly, suitable for various applications |

DTF Printer

The traditional DTF printer relies on excessive powder application to enhance the quality of prints. The process involves printing the design onto a transparent film, which is then placed on the printable surface and subjected to heat and pressure for transfer. While effective in creating vibrant prints, the excessive use of powder can be messy and time-consuming.

DTG Printer

The DTG printer, as the name suggests, prints directly onto garments using inkjet technology. It offers excellent print quality, especially for complex designs and intricate details. However, it is important to note that the DTG printer may have limitations when it comes to printing on certain materials, such as dark fabrics, and can be slower compared to other printing methods.

Powerless DTF Printer

The Powerless DTF printer is a revolutionary technology that eliminates the need for excessive powder application. By using a special transfer film, the ink is directly transferred onto the printable surface without the mess and inconvenience associated with traditional DTF printing. This innovative approach offers enhanced color vibrancy, increased durability, and higher printing speeds.

Pros and Cons of Each Technology

DTF Printer

Pros

- Vibrant color output: The excessive powder application allows for vibrant colors and sharp prints.

- Suitable for a wide variety of materials: DTF printing can be used on various surfaces, including textiles, ceramics, and more.

Cons

- Messy process: The use of excessive powder can create a messy printing environment.

- Time-consuming: The additional step of powder application adds time to the overall printing process.

DTG Printer

Pros

- High print quality: DTG printing offers excellent detail and color accuracy, especially for complex designs.

- Ideal for small print runs: DTG is well-suited for printing small quantities of garments, allowing for customization and personalization.

Cons

- Limitations with dark fabrics: DTG printers may struggle to achieve vibrant prints on dark-colored materials.

- Slower printing speed: Compared to other printing methods, DTG printing can be slower due to the detailed and precise nature of the process.

Powerless DTF Printer

Pros

- No excessive powder application: The elimination of excessive powder simplifies the printing process, making it more efficient and clean.

- Enhanced durability: Powerless DTF printing offers increased print durability, ensuring long-lasting and resilient prints.

- Higher printing speed: With the absence of powder application, the printing speed is significantly improved, increasing productivity.

Cons

- Limited to certain printable surfaces: Powerless DTF printing is most effective on flat surfaces and may not be suitable for all materials.

- Initial investment: Like any technological advancement, a powerless DTF printer may require an initial investment cost.

Which is Better?

Determining which printing technology is better, whether it’s a DTF printer, DTG printer, or a powerless DTF printer, is subjective and depends on individual needs. However, the powerless DTF printer offers a compelling advantage by combining the benefits of DTF and DTG printing while eliminating the downsides. It provides vibrant prints, increased durability, higher printing speeds, and a cleaner workflow without the need for excessive powder application. Ultimately, the decision should be based on specific requirements, such as budget, print volume, desired quality, and material compatibility. Consulting with industry professionals can help make an informed decision.

Is a Powerless DTF Printer Right for You?

Determining whether a powerless DTF printer aligns with your goals and objectives requires careful consideration. Evaluating your printing needs and requirements is crucial in making an informed decision. Factors such as budget, production volume, desired print quality, and time constraints, a reliable fabric printer manufacturer should be taken into account.

It is worth noting that a powerless DTF printer offers numerous advantages, including cost savings, enhanced print quality, and increased productivity. However, it may not be suitable for everyone. Consulting with industry professionals and conducting thorough research can help you determine if a powerless DTF printer is the right choice for you.

Conclusion

In summary, the future of printing lies in the power of a powerless DTF printer. By eliminating the need for excessive powder application, this innovative technology revolutionizes the printing industry, offering enhanced color vibrancy, higher printing speeds, lower production costs, and increased durability of prints. As technology continues to advance, the printing industry will witness further transformations, and the role of a powerless DTF printer will become even more prominent. Embracing this innovation and harnessing its power can open doors to creativity, efficiency, and profitability.