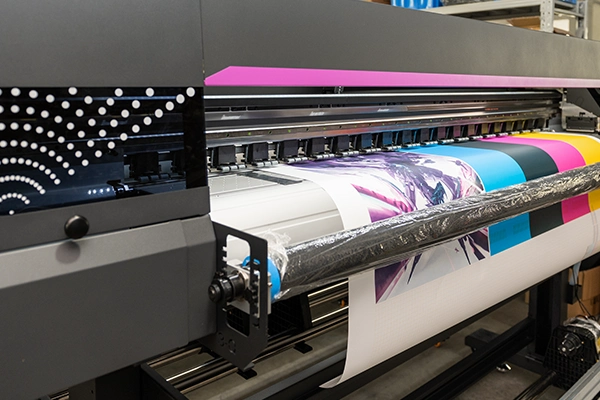

Wide Format Sublimation Printer

As a sublimation printer supplier and manufacturer, Xinflying provides a broad assortment of large format dye sublimation printers that are specifically manufactured for unique business plans and various industrial applications. All of them are constructed to offer a combination of reliable operation, exceptional quality, and blazing fast print output to help your business grow.

Diverse Lineup for Business Goals

A wide variety of single & multiple pass in small size and budget-friendly sublimation printers for startup businesses, as well as wide format sublimation printers and low labor cost printers for mega businesses.

XF-1800H Sublimation Printer

0-1800mm

12㎡/h (4 Pass)

1* Epson XP600

2700 x 730 x 1260mm

XF-1900 Sublimation Printer

0-1900mm

98㎡/h (2 Pass)

2* Epson I3200-A1

2820 x 840 x 1310mm

XF-5193 Sublimation Printer

1900mm

120㎡/h (2 Pass)

3* Epson I3200-A1

3210 x 950 x 1000mm

XF-5194 Sublimation Printer

1900mm

160 ㎡/h

3* Epson I3200-A1

3460 x 940 x 970mm

XF-5198 Large Format Dye Sublimation Printer

1900mm

370 ㎡/h

8* Epson I3200-A1

3900 x 1340 x 1535mm

XF-6198 Large Print Sublimation Printer

0-1900mm

370 ㎡/h

8* Epson I3200-A1

3900 x 1340 x 1980mm

XF-5328 Wide Format Sublimation Printer

0-3200mm

420 ㎡/h

8* Epson I3200-A1

5280 x 1180 x 1770mm

XF-51915 Large Format Sublimation Printer

0-1900mm

610 ㎡/h

15* Epson I3200-A1

3970 x 1300 x 1930mm

Adavanced Technology for Efficient Printing

Sophisticated sublimation printer machines equipped with lastest and convenient tech to make your business work smoothly and easily.

Automatic Nozzle Maintenance

Safe nozzle cleaning and moisturing system is automatically with handsfree maintenance, which preventing the nozzle from clogging and makes the printing operation more convenient.

Smart Ink Shortage System

Eliminate the need and demanding action of frequently checking the ink level as it features a system that gives low ink notification, thereby ensuring continuity of printing operation.

Infrared Dry System

Intelligently synchronized with printing, energy saving, and emission reduction. The temperature can be adjusted according to the current situation during printing.

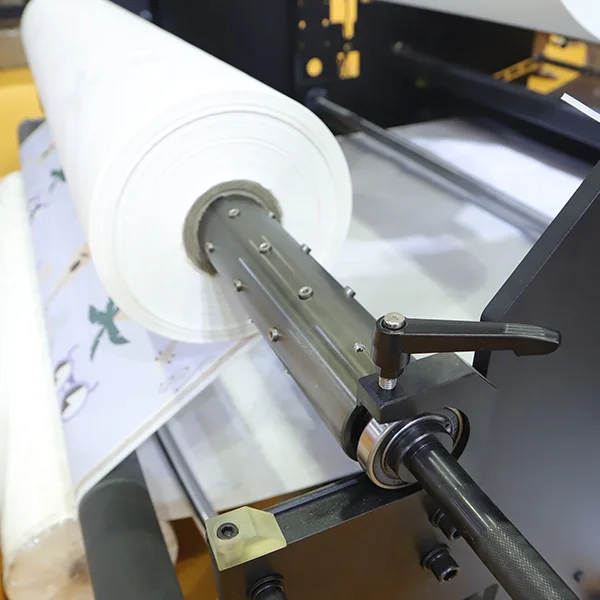

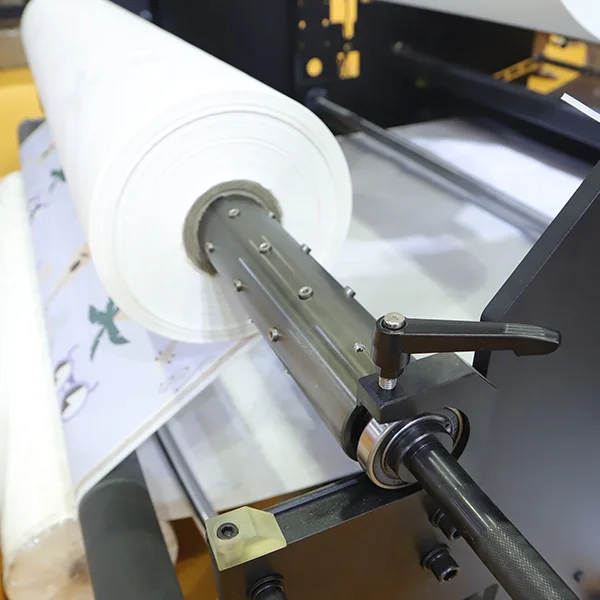

Auto Feeding & Taking Up

Auto-feeding and take-up paper system which makes the force evener and the paper smoother. This feature offers enough power to handle non-stop work and precise media movement.

Application for Wide Format Fabric

-

Sheet

Sheet

-

Flag

Flag

-

Curtain

Curtain

-

Sofa Cover

Sofa Cover

-

Carpet

Carpet

-

Apparel

Apparel

-

Advertising flag

Advertising flag

-

Advertising flag

Advertising flag

Start Printing Effortlessly

Free Demo & Sample

Free Demo & Sample

Fast Delivery

Fast Delivery

Technical Support

Technical Support

Life-time Warranty

Life-time Warranty

How to understand "pass" in digital printing?

Single pass: Many print heads are used to cover the whole substrate at once, which increases the total cost. But it produces high quality images at a fast speed.

Multiple passes: It costs less as a reduced number of printheads are needed. The printing process is quite slow as it goes over the substrate several times, but delivers better image quality as parts that were omitted at first will be done properly at the next pass.

Compatilble Sublimation Consumables

To help you run smoothly with better performance, Xin Flying, sublimation machine manufacturer, provides compatible consumables all in one stop.

How do Sublimation Printers Work?

Design Creation

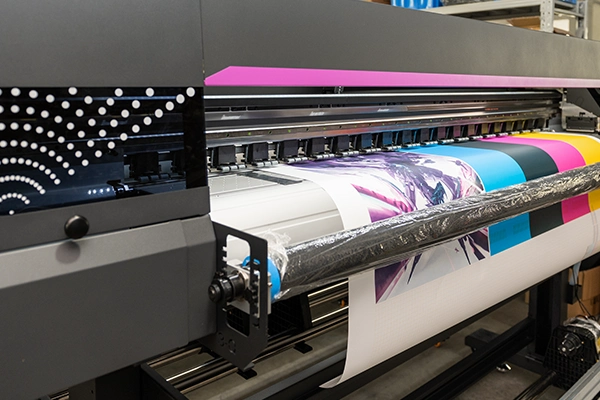

Printing on Sublimation Paper

Heat Pressing

Cooling and Finishing

Key Advantages of Sublimation Printer

High-quality Prints

Cost-effective

Full-color Capability

Minimal Setup Time

What can You Make with a Sublimation Printer?

Apparel

Home Decor

Promotional Items

Signage and Banners

Sports Equipment

Personalized Gifts

DTF Printer vs Sublimation Printer

| Printer Type | DTF Printer | Sublimation Printer |

|---|---|---|

| Printing Process | Printing on white polyester film and then transferring it onto the fabric with the help of a powder layer activated by heat | Heating ink and transferring the dye onto the fabric through sublimation |

| Printing Material | Printing on polyester and cotton fabrics, as well as other materials such as denim, leather, and nylon | Printing only on polyester and polymer-coated substrates such as ceramics, metal, and glass |

| Ink Used | White ink is used to print on colored fabrics | Dye ink is used to print on specifically coated substrates |

| Print Quality | Provides a vibrant and vibrant color on any kind of fabric. | Offers a soft-textured print with a low hand-feel in comparison to screen printing. |

| Durability | Provides high durability of prints with excellent wash and rub fastness | Inks don’t fade even after long exposure to outdoor elements |

| Cost | Requires a lesser initial investment and produces more economical prints | Requires an initial investment in equipment and additional cost for specifically coated substrates |