When it comes to printing designs on fabric, there are various methods available in the market. Two popular techniques are Direct-to-Fabric (DTF) printing and sublimation printing. In this blog, we will explore their basic principles, key differences, applications, pros and cons, and ultimately determine which method best suits specific requirements.

DTF Printing Basic

What Is DTF Printing?

DTF printing, also known as Direct-to-Fabric printing, is a cutting-edge technique used to transfer designs onto various types of fabric. This method involves printing designs onto a special film, which is then transferred to the fabric using heat and pressure. The process allows for high-quality, vibrant prints on a wide range of fabrics, making it a popular choice in the textile industry. Unlike traditional methods, DTF printing offers the flexibility to create intricate patterns and vivid images that stand out on garments.

How Does DTF Printing Work?

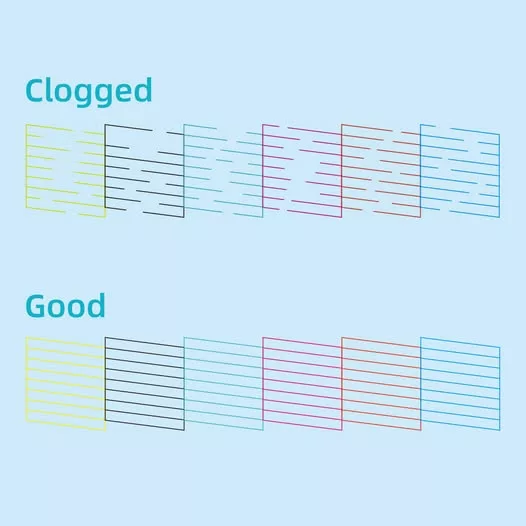

The process of how does DTF printing work begins with creating the desired design on a computer. Once the design is ready, it is printed onto a special film using DTF ink. The printed film is then placed onto the fabric, and both are subjected to heat and pressure using a heat press machine.

During this step, the ink from the film undergoes a phase change from solid to gas without passing through the liquid phase. This allows the ink particles to embed themselves directly into the fabric fibers, resulting in long-lasting and vibrant prints.

Sublimation Printing Basic

What Is Sublimation Printing?

Sublimation printing is a cutting-edge method used to transfer designs onto fabric using heat and pressure. This process involves the transformation of solid ink particles into a gas state without passing through the liquid phase. The gas then permeates the fabric and solidifies, resulting in vivid and durable prints. Unlike traditional printing methods, sublimation printing offers the flexibility to create complex patterns and images that remain vibrant even after multiple washes.

How Does Sublimation Printing Work?

The process begins with creating the desired design on a computer. Once the design is finalized, it is printed onto special sublimation paper using sublimation inks. The printed paper is then placed onto the fabric, and both are subjected to heat and pressure using a heat press machine.

During this step, the ink undergoes sublimation, transforming from a solid state directly into a gas state. The high temperature causes the ink particles to open up and merge with the fabric fibers, resulting in prints that are embedded within the fabric itself.

Key Differences Between DTF and Sublimation Printing

Now, let’s delve into the key differences between DTF vs sublimation printing, focusing on the application process, fabric compatibility, and color vibrancy.

Application Process

DTF printing involves transferring onto a film and then applying it to the fabric with heat and pressure. It offers more stability in transfers and the ability to store them long-term.

Sublimation printing transfers solid ink particles into a gas state without a liquid phase. This results in consistent color blooms and vibrant prints.

Fabric Compatibility

DTF printing is versatile and can be applied to a wide range of fabrics, making it suitable for various projects.

Sublimation printing works best on polyester and polymer-coated substrates, making it ideal for sportswear and personalized items.

Color Vibrancy

DTF printing offers vibrant results on any fabric color, while sublimation works best on light-colored fabrics and does not effectively print white.

Durability

DTF prints are durable and can withstand wear and tear, with transfers that resist fading and maintain clarity over time.

Sublimation prints are highly durable, especially on polyester, due to the gas-to-solid transformation of ink particles ensuring designs integrate into the fabric.

Pros and Cons of DTF Printing

Now that we have explored the basic principles of DTF and sublimation printing, let’s delve into the specific advantages and disadvantages of DTF printing. Understanding these key aspects will provide valuable insights into the suitability of this method for various applications.

Pros of DTF Printing

1. Vibrant colors

One of the standout advantages of DTF printing is its ability to produce vibrant and eye-catching colors on fabric. The process allows for exceptional color saturation, resulting in designs that pop with vividness. This feature makes DTF printing an ideal choice for applications where color vibrancy is a priority, such as fashion apparel, sports jerseys, and promotional merchandise.

2. Ideal for complex designs

Another significant benefit of DTF printing is its capability to render intricate and detailed designs with precision. Whether it’s intricate patterns, fine lines, or elaborate graphics, what is DTF printing excels in capturing the nuances of complex designs. This makes it a preferred choice for creating visually striking garments and accessories that demand high-resolution prints.

Cons of DTF Printing

1. Not suitable for all fabrics

While DTF printing offers versatility in terms of fabric compatibility, it may not be suitable for all types of fabrics. Certain specialized materials or blends may pose challenges when using this method, requiring decorators to carefully assess fabric characteristics before proceeding with DTF printing. It’s essential to consider factors such as fabric composition, texture, and weave to ensure optimal results.

2. Longer process compared to other methods

Another consideration when utilizing DTF printing is the time required for the entire process. From preparing the design and film to transferring it onto the fabric, this method typically involves a longer processing time compared to some alternative techniques. While the results are often worth the investment in time, decorators should factor in production timelines when choosing what is DTF printing for their projects.

Pros and Cons of Sublimation Printing

Now, let’s explore the specific advantages and disadvantages of sublimation printing. Understanding these key aspects will provide valuable insights into the suitability of this method for various applications.

Pros of Sublimation Printing

1. Durable prints

Sublimation printing offers exceptional durability, making it a preferred choice for applications that require long-lasting designs. The process involves transforming solid ink particles into a gas state, allowing them to permeate the fabric and solidify. This results in prints that are embedded within the fabric itself, enhancing their resistance to fading and wear. What is sublimation printing ensures that the designs maintain their vibrancy and clarity over time, even after multiple washes and prolonged use.

2. Suitable for a wide range of fabrics

One of the standout advantages of sublimation printing is its compatibility with a wide range of fabrics, including polyester and polymer-coated substrates. This versatility makes it ideal for various applications such as sportswear, promotional items, personalized gifts, and more. The ability to produce vibrant prints on different fabric types expands the potential uses of sublimation printing across different industries.

Cons of Sublimation Printing

1. Limited color options

One limitation of sublimation printing is its relatively limited color options compared to other printing methods. While it excels in producing vibrant colors on compatible fabrics, there may be constraints when attempting to achieve specific shades or hues. Decorators should carefully assess their color requirements and consider alternative methods if they seek a broader color spectrum for their designs.

2. Not ideal for dark fabrics

Another consideration when utilizing sublimation printing is its compatibility with fabric colors. This method is not ideal for dark-colored fabrics due to its reliance on a white base layer for optimal color vibrancy. While it excels in producing vivid prints on light-colored fabrics, decorators may need to explore alternative techniques when working with darker fabric shades.

Sublimation vs DTF, Which to Choose?

When deciding between sublimation and DTF (Direct-to-Film) printing methods, it’s important to consider your specific needs and the characteristics of each method. Here are some factors to consider when choosing between sublimation and DTF printing:

Fabric Type

Sublimation is typically used on polyester-based fabrics, while DTF can be used on a wider range of fabrics, including cotton, polyester, and blends. If you primarily work with polyester fabrics, sublimation may be the best choice. If you work with a variety of fabric types, DTF may offer more flexibility.

Color Vibrancy

Sublimation printing generally produces more vibrant and long-lasting colors compared to DTF printing. If color quality is a top priority for your projects, sublimation may be the better choice.- Detail and resolution: DTF printing allows for greater detail and resolution compared to sublimation printing. If you are working on intricate designs or patterns, DTF may offer better results.

Cost and Equipment

Sublimation printing requires specialized sublimation inks, printers, and transfer paper, which can be more expensive than DTF printing equipment. DTF printing may be a more cost-effective option for those looking to start a printing business on a budget.

Ease of Use

Sublimation printing involves a heat transfer process, while DTF printing requires the use of a hot melt powder and a heat press. Some users may find sublimation to be more straightforward and user-friendly, while others may prefer the greater control and customization options offered by DTF printing.

Environmentally Friendly

Sublimation printing is considered to be more environmentally friendly, as it produces minimal waste and does not require the use of water or solvents. DTF printing may produce more waste due to the transfer film used in the process.

Can I Use DTF Powder on Sublimation Paper?

No, DTF powder is not compatible with sublimation paper. DTF powder is designed for use with DTF films, while sublimation paper is used with sublimation inks for a different printing process. Mixing the two can result in poor transfer quality and damage to equipment. It’s important to use the correct materials for each printing method.

Is DTF Better Than Sublimation?

The choice between DTF (Direct-to-Film) and sublimation printing depends on your specific needs and preferences. Both methods have their own advantages and limitations:

DTF Printing

- Allows for printing on a wider range of fabrics, including cotton, polyester, and blends.

- Offers greater detail and resolution for intricate designs.

- Can achieve a more textured finish compared to sublimation.

- Allows for white ink printing on dark fabrics.

Sublimation Printing

- Produces vibrant and long-lasting colors, especially on polyester-based fabrics.

- More environmentally friendly, as it produces minimal waste and does not require water or solvents.

- Easy to use and ideal for printing on items like apparel, mugs, and promotional products.

- Suitable for high-volume production and mass customization.

Conclusion

In essence, decorators and manufacturers should carefully evaluate their specific requirements when choosing between DTF and sublimation printing methods. The decision should be based on factors such as application flexibility, fabric compatibility, color options, and durability considerations. Overall, both techniques offer valuable solutions for creating vibrant and durable prints on various fabrics, contributing to the ever-evolving landscape of textile decoration.