Sublimation printing is a popular technique used in the world of printing and customization. It involves transferring ink onto a substrate (such as fabric) using heat and pressure. This method results in vibrant, long-lasting prints that are ideal for custom designs and personalization. In this comprehensive guide, we will dive deep into the intricacies of sublimation printing, covering everything from the basics to advanced tips and troubleshooting techniques.

What Is Sublimation Printing?

Sublimation printing is a process where special sublimation inks are used to transfer designs onto a substrate, typically polyester-based materials. The ink is first printed onto sublimation paper and then transferred onto the fabric using a heat press. The heat and pressure cause the ink to sublimate, turning it into a gas that penetrates the fibers of the fabric, resulting in a permanent and vibrant print.

What Do I Need for Sublimation Printing?

When getting started with sublimation printing, there are a few essential tools and materials you will need:

- Heat press: A heat press is used to apply heat and pressure to the sublimation paper and fabric, helping transfer the ink onto the material.

- Sublimation printer: A specialized printer that uses sublimation inks to print designs onto sublimation paper.

- Sublimation paper: Specially coated paper that holds the sublimation ink before it is transferred onto the fabric.

- Sublimation inks: These inks are specially formulated to sublimate when subjected to heat, resulting in vibrant and long-lasting prints.

- Right fabric: Polyester fabrics work best for sublimation printing as they allow the ink to penetrate the fibers, resulting in bright and durable prints.

How Does a Sublimation Printer Work?

If you’re new to sublimation printing, here is a simplified step-by-step beginners guide to sublimation printing:

- Design Creation: Begin by creating your design on a computer using graphic design software. This design will be the image or artwork that you want to print onto your fabric.

- Printing onto Sublimation Paper: Once your design is ready, use a sublimation printer to print it onto specially coated sublimation paper. The printer will transfer the sublimation inks onto the paper with precision.

- Applying the Design onto Fabric: To transfer the design onto the fabric, place the sublimation paper with the printed design facing down onto the fabric. Ensure the design is positioned correctly on the fabric.

- Heat press: Use a heat press to apply heat and pressure to the fabric and the sublimation paper. This process causes the sublimation inks on the paper to turn into gas and permeate the fabric fibers, creating a vibrant and permanent print.

- Cooling and Finishing: Allow the fabric to cool before removing the sublimation paper. The cooling process helps the ink set and adhere to the fabric properly. Once cooled, carefully peel off the sublimation paper to reveal the colorful and durable print on the fabric.

By following these simple steps, you can successfully create custom designs and personalized prints using a sublimation printer.

Application of Sublimation Printing

Sublimation printing is a versatile and effective printing method that finds applications in various industries and settings. Here are some common applications of sublimation printing:

Apparel and Clothing

Sublimation printing is widely used in the apparel industry for creating custom fabrics, upholstery, and linens for custom-designed clothing, sportswear, and uniforms. The process allows for vibrant and long-lasting prints on polyester fabrics, making it ideal for athletic apparel and sublimated jerseys.

Home Decor and Accessories

From personalized pillows and blankets to custom mugs and coasters, sublimation printing is used to create unique home decor items and accessories. The process enables detailed and colorful prints on various substrates, enhancing the aesthetics of interior spaces.

Promotional Products

Sublimation printing is popular for producing promotional products such as keychains, mouse pads, and t-shirts with company logos or branding. The high-quality prints and customization options make sublimation printing an attractive choice for promotional merchandise.

Signage and Banners

Sublimation printing is also utilized in the creation of signage, banners, and flags due to its ability to produce vibrant and eye-catching graphics. The prints are durable and weather-resistant, making them suitable for both indoor and outdoor applications.

Personalized Gifts

Sublimation printing is perfect for creating personalized gifts such as photo frames, mugs, and phone cases. The process allows for the reproduction of intricate designs and photographs with excellent color reproduction and detail.

Sports Equipment and Accessories

Sublimation printing is commonly used to decorate sports equipment and accessories such as helmets, gloves, and bags. The prints are durable and resistant to wear and tear, making them ideal for sports-related applications.

Pros and Cons of Sublimation Printing

Sublimation printing offers a range of benefits and drawbacks that are essential to consider when deciding on its application. Let’s explore the pros and cons of sublimation printing.

Pros of Sublimation Printing

- Sublimation printing produces sharp, detailed, and long-lasting prints that resist fading over time.

- This method can seamlessly print on polyester fabrics and other synthetic materials, allowing for versatile customization options.

- Sublimation inks create vivid and enduring colors that stay vibrant wash after wash.

- Sublimation printing enables intricate and personalized designs, making it ideal for showcasing individual creativity.

Cons of Sublimation Printing

- Sublimation printing works best on polyester fabrics and may not be suitable for natural fibers like cotton.

- Due to the specialized equipment and consumables required, sublimation printing may not be economical for small or one-off printing projects.

- Operating a sublimation printer and heat press necessitates knowledge and training to ensure optimal results.

- While offering a broad color range, sublimation printing may not match the color variety of certain traditional printing methods.

- Sublimation printing is most effective on light-colored polyester fabrics, limiting its application on dark or non-polyester substrates.

Tips and Tricks for Success Sublimation Printing

To ensure successful sublimation printing, consider the following tips and tricks:

- Setting the right temperature and pressure on your heat press is crucial for optimal transfer of the ink.

- Using the correct color profiles for accurate color representation will result in vibrant and true-to-life prints.

- Pre-treating fabric for better ink absorption can improve the quality and longevity of the prints.

Troubleshooting Common Issues

- If your prints are fading or appearing dull, try increasing the temperature and pressure on your heat press to ensure proper ink transfer.

- Blurred images can result from improper printing settings. Check your printer settings and ensure the design is printed at the appropriate resolution.

- Uneven transfer of the design onto the fabric may be caused by uneven pressure on the heat press. Adjust the pressure and ensure even distribution for a consistent print.

How to Maintain Your Sublimation Printer

- Cleaning your heat press: Regularly clean your heat press by wiping down the surfaces and removing any residue to ensure optimal printing results.

- Refilling sublimation ink cartridges: Keep your sublimation ink cartridges filled to avoid running out of ink in the middle of a project. Follow the manufacturer’s instructions for refilling.

- Storing sublimation paper properly: Store your sublimation paper in a cool, dry place to prevent moisture damage and ensure the quality of your prints.

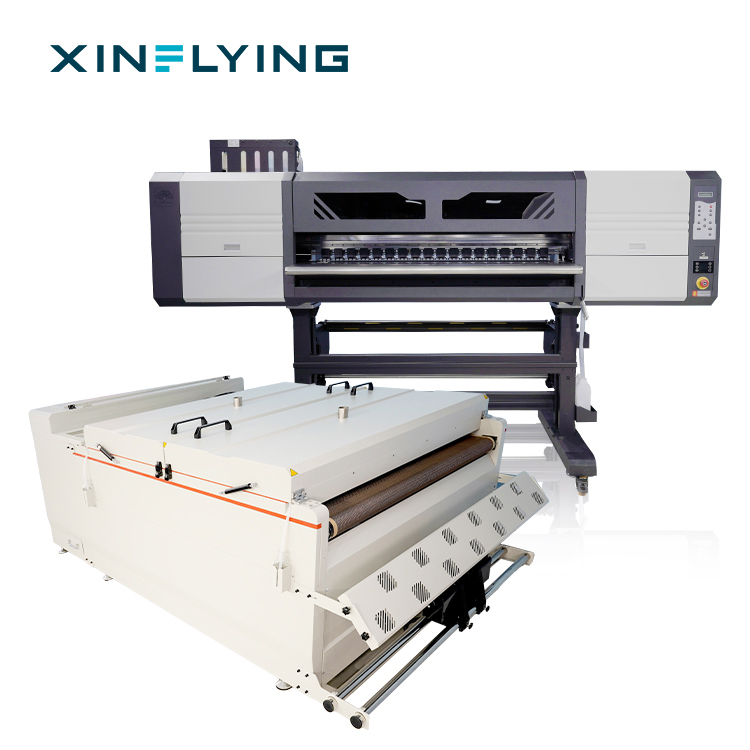

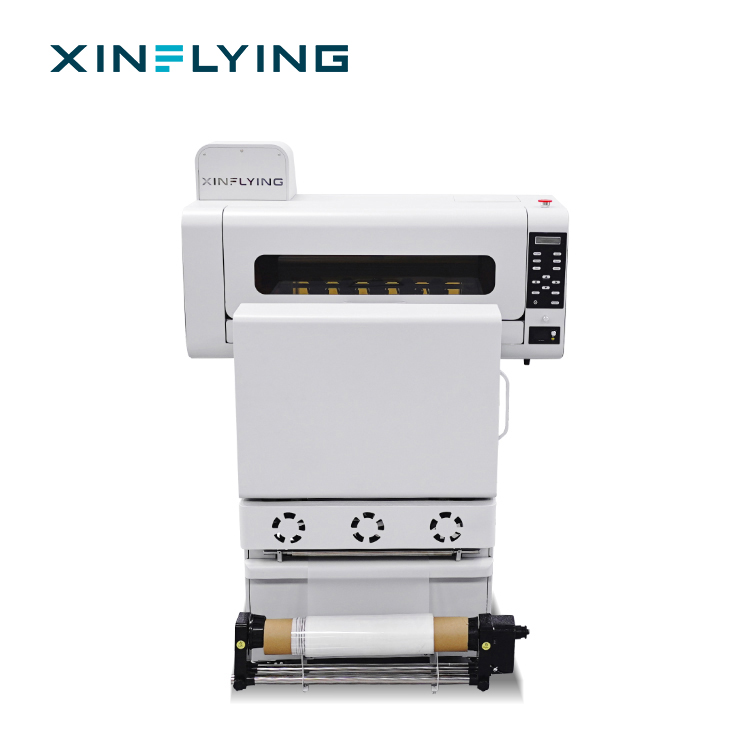

What Is a Good Sublimation Printer?

When selecting a sublimation printer, there are several factors to consider to ensure optimal performance and quality prints. Here are some key features to look for in a good sublimation printer:

- Dye Sublimation Technology: Choose a printer specifically designed for dye sublimation printing to ensure compatibility with sublimation inks and paper.

- Print Resolution: Look for a printer with high resolution capabilities (at least 1200 dpi) to achieve sharp and detailed prints.

- Ink Compatibility: Ensure the printer is compatible with sublimation inks and has separate color ink cartridges for efficient printing.

- Media Handling: Select a printer with a wide media compatibility range to accommodate various paper sizes and types for versatile printing options.

- Speed and Efficiency: Consider the printing speed of the printer to ensure efficient production without compromising print quality.

- Software Integration: Look for a printer that integrates seamlessly with sublimation software for easy design processing and printing.

- Cost-effectiveness: Consider the initial investment cost, as well as the ongoing maintenance and ink refill expenses, to determine the overall cost-effectiveness of the printer.

- User-Friendly Interface: Opt for a printer with a user-friendly interface and intuitive controls for easy operation, especially for beginners.

Conclusion

In conclusion, sublimation printing is a versatile and high-quality printing method that is perfect for custom designs and personalization. By understanding the process, equipment, and tips for success, you can achieve professional and long-lasting prints. For all your sublimation printing needs, consider XinFlying, a leading textile printer manufacturer of industrial sublimation printers, inks, and paper that can be customized for your business applications. Choose high-quality sublimation printing solutions from XinFlying for outstanding results.