Introduction: POD’s Automation Era Has Begun

The global Print-on-Demand (POD) industry is no longer emerging—it is accelerating at record speed. According to industry research, POD is projected to maintain a compound annual growth rate exceeding 25% over the next five years.

What’s fueling this rapid expansion? Three unstoppable forces are converging:

- Consumers increasingly demand highly personalized products

- E-commerce platforms have dramatically lowered the barrier to entry

- Automation and AI technologies are redefining manufacturing efficiency

In this environment, DTF printing combined with automated production is no longer optional—it is the foundation of competitiveness.

At Xinflying, we focus on delivering stable, scalable, and automation-ready POD solutions for global apparel manufacturers and POD operators.

Note: Performance metrics may vary depending on materials, workflows, and operating conditions. Figures shown are for reference only.

The POD Shift Is Permanent—And It’s Accelerating

The explosive growth of POD is not a coincidence. It is the natural result of digital manufacturing colliding with modern consumer behavior.

Small Orders Are the New Standard

With digital processes such as DTF and UV DTF, traditional minimum order quantities have effectively disappeared. Brands can now launch, test, and scale products with almost zero inventory risk.

This flexibility allows businesses to respond instantly to trends—turning POD into the most agile production model available.

AI Is Redefining Design Economics

Design creation is no longer a bottleneck. AI-powered tools now allow designers to generate hundreds or thousands of print-ready designs daily, dramatically reducing cost and time-to-market.

These designs can be uploaded instantly to platforms like Shopify, Etsy, or Shein, where speed and novelty define success.

E-commerce Provides Unlimited Demand

With global e-commerce surpassing $26 trillion, POD businesses are operating in an environment of massive, constant demand.

The combination of zero inventory + fast fulfillment makes POD the most efficient route to monetizing creativity today.

Your Printer Is Not Equipment—It Is Your Business Engine

In POD manufacturing, the printer defines your margins, delivery speed, and scalability.

Any instability or inefficiency in production directly translates into lost orders.

Four Non-Negotiables for POD Profitability

- Print Quality: High saturation, clarity, and durability are essential for brand trust

- Production Speed: Faster turnaround drives customer satisfaction and repeat orders

- Process Flexibility: The ability to print on multiple materials expands product categories

- Cost Control: Low setup cost and consistent unit economics make small orders profitable

Why Traditional Printing Falls Short

- High MOQs make personalization expensive

- Plate-making increases cost and delays delivery

- Long preparation cycles conflict with e-commerce speed

- Limited material compatibility restricts product innovation

In POD, success depends on how efficiently you convert digital designs into finished products—and that efficiency begins with the right printing technology.

DTF Printing: The Core Engine of Apparel POD Automation

Modern POD is defined by small batches, high frequency, and multiple SKUs—a scenario where traditional printing struggles.

DTF technology solves these challenges and has become the core engine of automated apparel POD.

Faster: Built for E-commerce Speed

DTF eliminates plate-making entirely. Once an order is placed, printing begins immediately.

- True on-demand production

- 2–3× efficiency compared to traditional methods

- Faster delivery = stronger customer retention

Factories operating DTF systems in dual shifts commonly handle 10,000–20,000 garments per day.

Lower Cost: Automation Reduces Labor Dependency

DTF workflows minimize manual intervention:

- Reduced setup and error rates

- Labor costs typically reduced by 30% or more

- Single-piece orders remain profitable

This allows businesses to reallocate labor and capital toward branding, marketing, and design.

Stability: Designed for Continuous Production

Order spikes are unavoidable in POD. DTF systems from Xinflying are engineered for 24/7 continuous operation, ensuring consistent output even during peak seasons.

Reliability enables confident participation in major sales events such as Black Friday and holiday campaigns.

DTF Delivers:

- Faster throughput

- Lower operating cost

- Stable, scalable production

It transforms your operation from labor-driven to process-driven manufacturing.

Automation Starts with a Barcode

When handling thousands of orders daily, manual sorting becomes a risk.

In Xinflying’s automated POD solution, the barcode is the backbone of end-to-end automation.

How the Barcode Controls the Workflow

- One barcode binds order data across RIP → printing → curing → sorting → packaging

- Software and hardware operate in sync

- Errors are instantly traceable

Automated Workflow Overview

- Order placed → barcode generated

- RIP software automatically matches design files

- Printing and powder curing proceed automatically

- Sorting system routes products by barcode

- Final verification before shipment

Why Barcodes Matter

- Drastically reduced error rates

- Faster fulfillment

- Lower training and labor costs

- Full production traceability

This system completes the shift to a fully process-controlled factory.

POD Success Requires More Than a Printer

Supplying a printer alone is no longer sufficient. True scalability requires full-process automation, integrating both software and hardware.

Automated Folding & Packaging

Post-processing is a major labor drain. Automation delivers:

- Consistent, professional packaging

- Reduced manual labor

- Savings equivalent to 2+ full-time employees annually

Intelligent Sorting & Conveyor Systems

High-volume operations demand precision:

- Barcode-based routing

- Accurate order aggregation

- Reduced returns and complaints

Roadmap to Full Automation

Xinflying continues to invest in:

- Automated cutting systems

- Automated heat press modules

- Fully integrated packaging lines

The goal: end-to-end unmanned POD production.

Practical Guide for POD Entrepreneurs

Step 1: Identify Your Niche

Use data from Google Trends, social platforms, and marketplaces. Depth beats breadth.

Step 2: Choose the Right Technology

- DTF: Apparel POD standard

- UV DTF: Rigid promotional products

- Sublimation: Polyester-focused items

Step 3: Optimize Design Workflow

AI + efficient software dramatically shortens fulfillment cycles.

Step 4: Select the Right Sales Platform

Shopify, Etsy, Amazon—choose based on brand strategy.

Step 5: Master Visual Marketing

TikTok, Instagram, influencer partnerships drive conversion.

POD Printing Technology Comparison

| Technology | Best Use | Key Advantage | Limitation |

|---|---|---|---|

| DTF | Apparel POD | Versatile, durable, vibrant | None for apparel |

| UV DTF | Rigid items | 3D effects | Not for fabric |

| Sublimation | Polyester | Soft feel | Material limits |

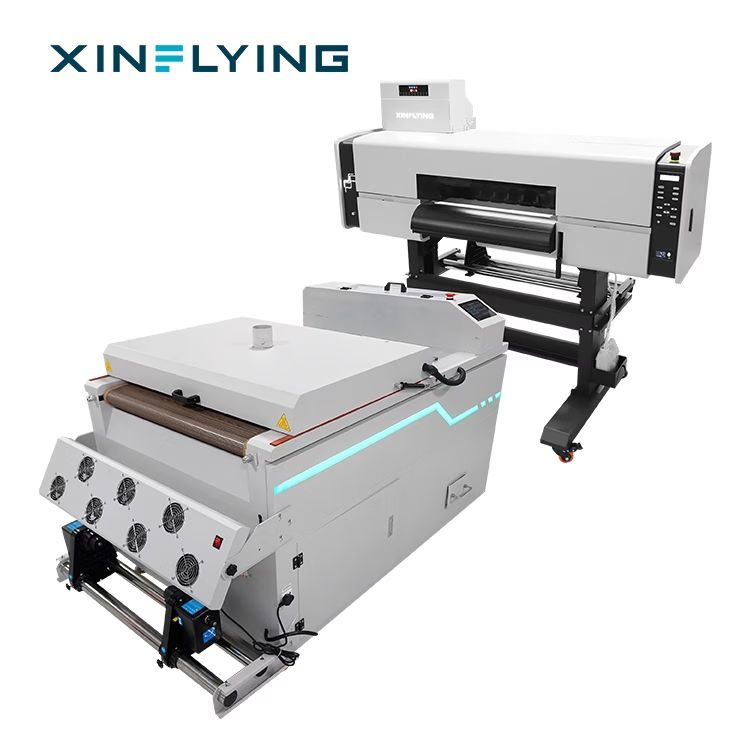

Why Choose Xinflying DTF Systems?

- Designed for high-frequency, multi-SKU apparel orders

- Seamless integration with automation lines

- Easily scalable from studio to factory

Xinflying DTF systems are not just printers—they are production platforms.

The Hidden Costs That Define Profitability (TCO)

True profitability lies in Total Cost of Ownership, not sticker price.

- Power Consumption: Lower energy usage saves thousands annually

- Downtime Risk: Stability prevents lost orders

- Maintenance: Modular design reduces long-term costs

- Labor & Training: Automation shortens onboarding

- Technical Support: Fast response protects revenue

Xinflying systems are engineered to minimize TCO from day one.

Why Xinflying?

- 10+ years of global industry experience

- Flexible solutions for all production scales

- Full-process technical support

- Energy-efficient, automation-ready designs

- Continuous optimization driven by customer feedback

Conclusion & Call to Action

The POD industry is growing at 25%+ annually, and automation is the deciding factor between survival and leadership.

With Xinflying, you gain:

- Faster production

- Lower TCO

- Long-term competitive advantage

👉 Explore Xinflying DTF Solutions

👉 Request an Automated Production Line Plan

👉 Consult with Our POD Automation Experts

Now is the time to build a POD operation ready for the next 2–3 years of growth.