Direct-to-Film (DTF) printing has rapidly become one of the most popular garment printing technologies for small studios, print shops, and growing customization businesses. Compared with DTG or traditional heat transfer methods, a DTF printer offers higher versatility, lower technical barriers, and excellent print quality across a wide range of materials—including cotton, polyester, blends, leather, and more.

If you’re planning to invest in a DTF printer, this guide will walk you through everything you need to know: how DTF works, key factors to consider, common pitfalls, and tips for choosing the right model for your business.

What Is a DTF Printer?

A DTF printer is a digital printing machine that prints designs onto PET film using specialized DTF inks. After printing, the film is coated with hot-melt powder, cured, and then heat-pressed onto garments. This technology creates durable, stretchy, and high-vibrancy prints suitable for both light and dark fabrics.

Why DTF Printing Is Popular

- Works on almost all fabric types

- Bright colors and strong wash durability

- No pretreatment required

- Cost-effective for small and large batches

- Perfect for T-shirts, hoodies, bags, uniforms, and promotional items

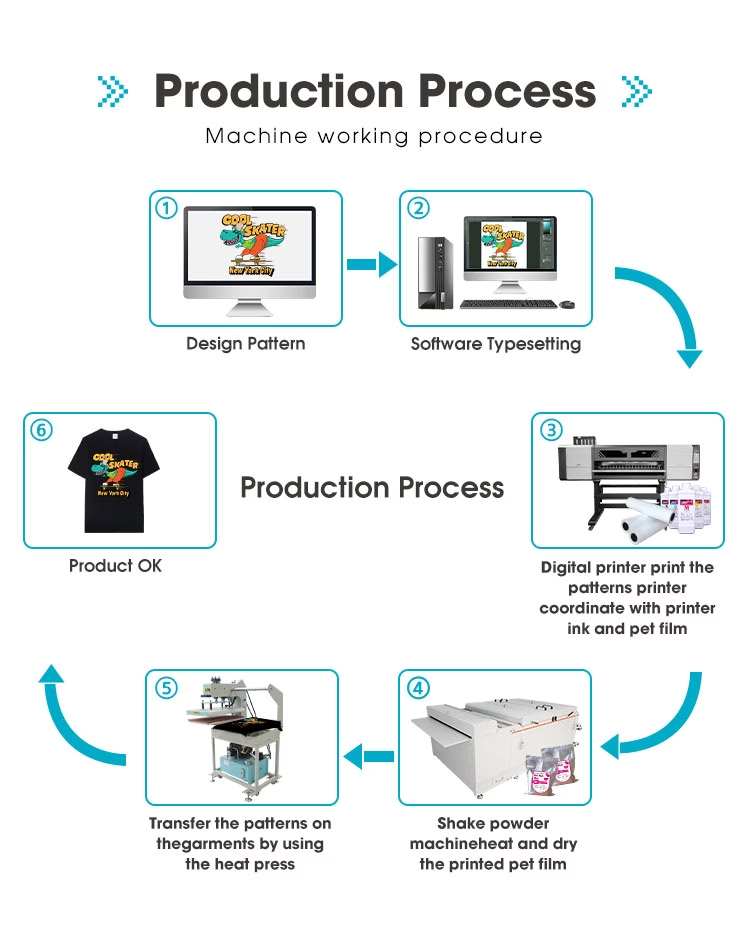

How a DTF Printer Works (Step-by-Step)

- Print the design on PET film using CMYK + White DTF inks

- Apply hot melt powder evenly

- Cure the powder with a curing oven or heat press

- Heat press the design onto the garment

- Peel the film (hot peel or cold peel depending on your film type)

Key Factors to Consider When Buying a DTF Printer

1. Printer Size & Print Width

Choose based on your business scale:

- A4/A3 DTF printers – ideal for beginners, small studios

- 30cm (12-inch) DTF printers – most popular for apparel startups

- 60cm (24-inch) wide-format DTF printers – suitable for bulk production

- 1m+ industrial DTF printers – for high-volume factories

If you expect to scale your business quickly, consider starting with a 60cm DTF printer.

2. Print Head Technology

Common Epson print heads:

- XP600 – budget-friendly, good for beginners

- I3200-A1 – stable and faster, ideal for small/medium business

Look for:

- Multiple print heads for speed

- Stable ink system

- Easy plug-and-play maintenance

3. Printing Speed & Productivity

Speed is crucial when fulfilling large orders.

Check:

- Prints per hour

- Whether printing and shaking powder are automatic

- Whether you need a manual or automatic curing oven

For production-level use, an integrated DTF printer with shaker and oven saves a lot of labor costs.

4. Ink Quality & Color Performance

Using high-quality DTF inks is essential for:

- Smooth ink flow

- Vibrant colors

- Durable prints

- Preventing clogging

Choose inks supported by your print head for optimal performance.

5. Film & Powder Compatibility

PET film and hot melt powder affect:

- Brightness

- Hand feel

- Washability

- Peel smoothness

Choose:

- Premium PET film (hot peel or cold peel)

- High-quality TPU hot melt powder

6. Software & RIP Compatibility

A good RIP software ensures:

- Smooth white ink layering

- Accurate color management

- Faster workflow

Popular RIPs:

- Acrorip

- Maintop

- Photoprint

- FlexiPrint

Make sure the printer you buy includes a licensed RIP.

7. Stability, Maintenance & After-Sales Support

DTF printers require regular maintenance, including:

- Daily nozzle checks

- Proper humidity control

- Cleaning capping and wiper pads

Choose a brand with:

- Local service support

- Training resources

- Easy-to-find spare parts

DTF Printer Pricing: What Should You Expect?

Approximate price range:

- Desktop A4/A3 DTF printer: $300–$1,000

- 30cm DTF printer: $1,500–$3,500

- 60cm DTF printer + shaker + oven: $4,000–$8,000

- Industrial DTF printer: $10,000+

Always compare:

- Speed

- Print head quantity

- Warranty

- Consumable cost

Common Mistakes First-Time Buyers Make

Avoid these pitfalls:

- Buying too small of a printer (business outgrows it fast)

- Using cheap inks that damage the print head

- Ignoring after-sales support

- Not checking the RIP software compatibility

- Choosing non-integrated systems that slow down production

Which DTF Printer Is Best for You? (Quick Guide)

For Beginners

- A4/A3 or 30cm DTF Printer

- Low startup cost

- Great for T-shirt shops & online stores

For Growing Print Shops

- 60cm DTF printer with shaker + oven

- Higher speed, better return on investment

For Mass Production

- Industrial dual-head or multi-head DTF printer

- Designed for 24/7 printing

Conclusion

Choosing the right DTF printer depends on your production needs, budget, and long-term business goals. Whether you are launching a small custom apparel store or expanding a large print operation, a high-quality DTF system can significantly boost your efficiency, print quality, and profitability.