Source: https://www.silhouetteschoolblog.com

Digital printing has revolutionized the garment and textile industry, offering businesses the ability to produce high-quality and customized products with ease.

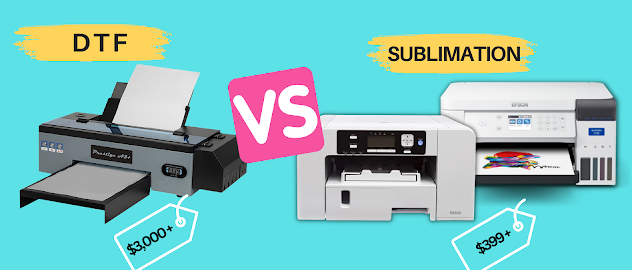

DTF printing and sublimation printing are two popular digital printing methods that have gained widespread use. While both technologies offer several advantages, there are significant differences between the two.

In this article, we will compare DTF printing and sublimation printing and explore their benefits, limitations, and suitability for different printing needs.

We’re breaking it all down in a super digestible way, so you can finally confidently choose the digital print method that best aligns with your business needs. Whether you’re a small-scale business or a large-scale manufacturer, this article will help you make the right choice for your printing needs.

[Table] What Are the Differences Between DTF Printing and Sublimation Printing?

| Comparison | DTF Printing | Sublimation Printing |

| Workflow | 1. Design on the Computer 2. Print on the PET film 3. Cure ink with adhesive powder 4. Heat Press to transfer the design | 1. Design on the Computer 2. Print on the sublimation paper 3. Heat Press to transfer the design |

| Material | A wider range of fabrics, including cotton, polyester, and blends | Polyester or polyester-coated materials, including apparel, banners, and promotional items. |

| Print quality | High-quality and detailed prints, more vibrant and detailed prints | High-quality and detailed prints |

| Production efficiency | Faster turnaround times and more efficient production | Suit for small quantities |

| Cost | Expensive | Expensiive but affordable for small quantities of custom products |

DTF vs Sublimation Comparison Table

What is DTF Printing?

Source: https://www.brildor.com

DTF (Direct-to-Film) printing is a digital printing technology that allows for high-quality and detailed designs to be printed directly onto transfer film, which can then be used to transfer the design onto fabric.

DTF printing is similar to DTG (Direct-to-Garment) printing, but instead of printing directly onto the fabric, the design is printed onto transfer film, which is then applied to the fabric using a heat press.

How Does DTF Printing Work?

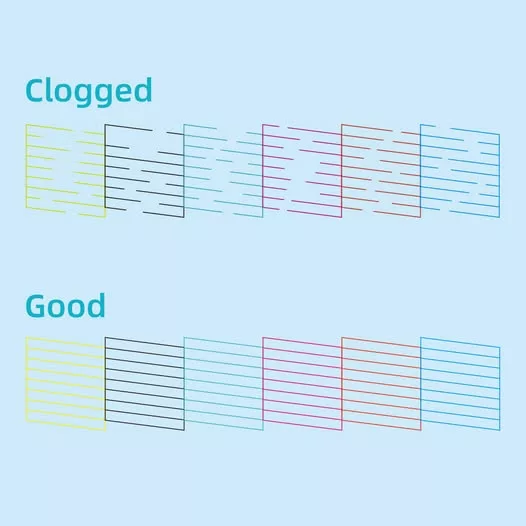

DTF printing technology uses a specialized printer that is designed to print onto transfer film using specialized DTF inks. The printer applies the ink onto the transfer film, which is then coated with a layer of DTF powder.

The DTF film is then placed onto the fabric and applied using a heat press. The heat melts the DTF powder, which fuses the ink onto the fabric fibers, resulting in a high-quality and durable print.

Advantages of DTF Printing

DTF printing offers several advantages over traditional sublimation printing methods, including:

- DTF printing offers the ability to print on a wide range of fabrics, including cotton, polyester, and blends.

- It produces vibrant and detailed prints that are long-lasting and resistant to fading and washing.

- DTF printing offers faster turnaround times and more efficient production compared to traditional sublimation printing methods.

- DTF printing offers the ability to print on a wider range of products, including shoes, hats, and bags.

Limitations of DTF Printing

While versatile, DTF has some limitations as following:

- Limited substrate compatibility – DTF printing works best on certain fabrics like cotton, polyester, and cotton/poly blends. It may not adhere well or produce desired results on some other materials like nylon or leather.

- Potential for cracking or fading;

- White underbase required for light fabrics;

- Not ideal for large order volumes;

- Limited stretchability.

What is Sublimation Printing?

Source: https://www.allprintheads.com

Sublimation printing is a digital printing method that uses heat and pressure to transfer dye onto a material, typically polyester or polyester-coated products.

The process involves printing the design onto sublimation paper using specialized sublimation inks, which are then transferred onto the material using a heat press.

How Does Sublimation Printing Work?

Sublimation printing works by using heat to convert the ink into a gas, which then bonds with the material’s fibers. This process results in a durable and long-lasting print that is resistant to fading, peeling, and cracking.

Sublimation printing is commonly used to print on a variety of products, including apparel, banners, signage, and promotional items. It is a popular choice for businesses that require full-color printing and customization of small quantities.

Advantages of Sublimation Printing

- Sublimation printing produces vibrant and detailed prints that are long-lasting and resistant to fading and washing;

- It is a versatile printing method that can print on a wide range of products, including apparel, banners, and promotional items;

- Sublimation printing is an affordable printing method for small quantities of custom products.

- It offers the ability to produce full-color prints with fine details and gradients.

Limitations of Sublimation Printing

- Limited to polyester or polymer-coated substrates – Sublimation printing only works on materials with a polyester coating or high polyester content like performance fabrics. It cannot be used on natural fibers like cotton or linen.

- Dye migration or ghosting.

- Not suitable for complex products – Products with many seams, ridges or uneven surfaces can produce inconsistent sublimation results.

- Production time is relatively time-consuming compared to other print methods.

Which is Better for Your Business, DTF or Sublimation Printing?

Source: https://www.shutterstock.com

When it comes to choosing a digital printing method for your business needs, there are several factors to consider.

Factors to Consider

When deciding which printing method is best for your business needs, consider the following factors:

- Fabric/Material

If you need to print on a wide range of fabrics, including cotton, polyester, and blends, DTF printing may be the better option. However, if you only need to print on polyester or polyester-coated materials, sublimation printing may be more suitable.

- Print quality

Both DTF printing and sublimation printing offer high-quality and detailed prints. However, DTF printing may offer more vibrant and detailed prints compared to sublimation printing.

- Production efficiency

DTF printing offers faster turnaround times and more efficient production compared to sublimation printing.

- Cost

Both DTF printing and sublimation printing require specialized equipment and consumables, which can be expensive. Consider your budget and the cost per print when deciding which method is best for your business needs.

FAQs On DTF Printing vs. Sublimation Printing

1. What do You Need for DTF Printing?

A DTF (Direct-to-Film) transfer involves printing a design onto a DTF film, which is then transferred onto a substrate using an adhesive. You need these for DTF printing:

- DTF printer

- Heat press machine

- DTF ink

- DTF PET film

- DTF adhesive powder

2. What do You Need for Sublimation Printing?

A sublimation transfer involves printing a design onto sublimation transfer paper using sublimation ink. Prepare these before starting sublimation printing:

- Sublimation printer

- Sublimation ink

- Sublimation paper

3. Can you use DTF paper with sublimation ink?

DTF paper is specifically designed for use with DTF ink, which is different from sublimation ink. Therefore, it is not recommended to use DTF paper with sublimation ink as they have different properties and require specific compatibilities.

4. Is sublimation paper the same as transfer paper?

Sublimation paper is a type of transfer paper specifically designed for sublimation printing. It is used to transfer a design onto a substrate by applying heat. While all sublimation papers are transfer papers, not all transfer papers are necessarily designed for sublimation printing.

5. Can you use DTF powder on sublimation paper?

DTF powder is used in the DTF printing process for adhesion between the design and the substrate. It is not typically used with sublimation paper as sublimation printing relies on the ink’s ability to transform into a gas and permeate the material, rather than using powder for adhesion.

6. Can you use sublimation ink for DTF printing?

No, sublimation ink cannot be directly used for DTF printing. DTF ink is a specific type of ink formulated for DTF printing, while sublimation ink is designed for a different printing process.

7. Is DTF ink the same as sublimation ink?

No, DTF ink is not the same as sublimation ink. They have different compositions and properties, tailored for their respective printing techniques. DTF ink is used for printing on a film that is then transferred to garments, while sublimation ink is used for a process where the ink turns into a gas and permeates the fabric.

Key Takeaway

In the end, DTF printing and sublimation printing are two viable digital printing methods with their own unique strengths and limitations. When deciding which printing method to choose, businesses should consider their specific printing needs, budget, and desired print quality.

As printer manufacturers continue enhancing these technologies, businesses must stay informed on the latest developments. Carefully weighing the pros and cons of each method against your requirements ensures you select the ideal digital printing solution. Both DTF and sublimation printing can produce high-quality customized products when implemented properly.

Ready to take your printing operations to the next level? Connect with our team of experts to assess your unique needs and get tailored recommendations on the best DTF or sublimation setup for your business goals.