Source: https://www.indiamart.com

Sublimation printing is a popular method for creating high-quality and long-lasting prints on various substrates, from fabrics to ceramics and metal. However, achieving vibrant and long-lasting sublimation prints requires more than just the right equipment and materials. It requires expertise in every stage of the sublimation printing process, from design preparation to post-printing techniques.

In this article, we will explore the essential steps to achieve vibrant and long-lasting sublimation prints, including selecting the right materials, preparing the design, proper printing techniques, post-printing techniques, and troubleshooting common issues. By following these steps, you can create sublimation prints that are not only visually stunning but also durable and long-lasting.

Choose the Right Substrate

Source: https://plasticsdecorating.com

When it comes to sublimation printing, the choice of substrate is crucial for achieving high-quality and long-lasting prints. Here are some tips for choosing the right substrate:

Polyester

Sublimation printing works by transferring dye onto a substrate through heat and pressure. Polyester is the most common substrate used in sublimation printing because it has a high affinity for dyes and can withstand the high temperatures required for the transfer process. Make sure the polyester substrate you choose is specifically designed for sublimation printing.

Light-colored and Smooth Surfaces

Sublimation printing works best on light-colored and smooth surfaces because it allows the dye to be fully absorbed and create vibrant colors. Dark and textured surfaces can interfere with the transfer process and result in less vibrant colors.

Consider the Application

Consider the intended application of the printed product when choosing a substrate. For example, if you are printing on a t-shirt, you will want a substrate that is comfortable to wear and can withstand washing and wear.

Choose the Right Sublimation Ink

Source: https://www.pinterest.com.au

Choosing the right sublimation ink is crucial for achieving high-quality and long-lasting prints in sublimation printing. Here are some tips for choosing the right sublimation ink:

Match the Ink to the Printer

Sublimation inks are specifically designed to work with certain printers, so it’s important to choose an ink that is compatible with your printer model.

Quality and Consistency

Look for sublimation inks that are high-quality and provide consistent results. Low-quality inks can result in poor color reproduction, bleeding, and reduced durability.

Color Gamut

The color gamut, or range of colors that can be reproduced, is an important consideration when choosing sublimation ink. Look for inks that offer a wide color gamut for more accurate and vibrant color reproduction.

Durability

Sublimation inks should be durable and able to withstand washing, sunlight, and other environmental factors. Look for inks that are specifically designed for high durability and longevity.

Choose the Right Sublimation Transfer Paper

Source: https://www.pinterest.com.au

The quality of sublimation paper can affect the vibrancy and longevity of sublimation prints. Low-quality transfer paper may not absorb the ink properly, resulting in dull colors and reduced durability. High-quality transfer paper with a special coating can enhance the sublimation process, resulting in more vibrant colors and improved durability.

There are different types of transfer papers and coatings used in sublimation printing. Tacky transfer paper has a sticky layer that helps keep the substrate in place during the transfer process. Quick-dry transfer paper reduces drying time, while regular transfer paper is more affordable. Transfer paper can be one-sided or two-sided, with coatings that enhance color vibrancy and reduce ghosting or bleeding.

To achieve high-quality and long-lasting prints in sublimation printing, it’s crucial to choose the right sublimation transfer paper. Here are some tips:

- Match the paper to your printer, ensure quality and consistency.

- Consider coated papers for better color vibrancy and reduced ghosting.

- Pick the appropriate weight and size for your application.

- Factor in environmental impact, and balance cost with lifespan and yield.

- Low-quality transfer paper may result in poor color reproduction, bleeding, and reduced durability.

Proper Printing Technique

Source: https://sellmerch.org

Ensuring accurate color reproduction, sharpness, and durability in sublimation printing requires the use of proper printing techniques. Temperature, pressure, and time settings must be correct to prevent poor transfer quality and reduced lifespan of the final product due to under or over-pressing. Thus, correct printing technique is crucial in sublimation printing.

To achieve vibrant and long-lasting sublimation prints, it’s important to adjust the heat press time and temperature to match the substrate and ink.

- Avoid improper pressure that can cause under or over-pressing.

- Use high-quality sublimation ink, transfer paper, and substrate.

- Maintain proper equipment calibration and cleaning.

It’s important to test prints before running full production in sublimation printing. This allows you to identify any issues or problems with the design, color, or transfer process before producing a large quantity of prints.

Testing also helps you to fine-tune the settings and adjust the design as needed to achieve optimal results. Use a small sample of the substrate and transfer paper to test the print, and make sure to record the settings used for future reference. Once you are satisfied with the test print, you can proceed with full production with greater confidence in the quality and consistency of the final product.

Proper Post-Printing Technique

Source: https://www.prodigi.com

Proper post-printing technique is essential in sublimation printing to achieve high-quality and long-lasting prints. Cooling down the print before handling or packaging prevents smudging or sticking, while trimming excess paper and washing the substrate ensure a clean finish. Proper handling and storage prevent damage, fading, and discoloration of the print, while regular equipment cleaning maintains optimal performance and prevents contamination.

In summary, following proper post-printing techniques is crucial for ensuring the durability and quality of the final product.

- Allow the print to cool

After transferring the design onto the substrate, allow the print to cool down before handling or packaging. This will prevent smudging or sticking of the print.

- Trim excess paper

Trim excess paper from the edges of the substrate to achieve a clean finish.

- Wash the substrate

For fabrics, wash the substrate before use to remove any residual coatings or oils that may interfere with the sublimation print. Use a mild detergent and do not use fabric softeners.

- Handle with care

Avoid rough handling of the substrate to prevent damage to the print.

- Store properly

Store the finished product in a dry and cool place away from direct sunlight to prevent fading and discoloration.

- Clean the equipment

Clean the heat press and other equipment regularly to maintain optimal performance and prevent contamination.

Ensuring Proper Environment for Printing

Source: https://www.zenoffice.com

Ensuring a proper environment for printing is important in sublimation printing to achieve consistent and high-quality results. Here are some tips to follow:

- Temperature and humidity control

Sublimation printing works best in a controlled environment with stable temperature and humidity levels. The ideal temperature range is between 68-75°F, and relative humidity should be kept between 45-55%.

- Proper ventilation

Adequate ventilation is essential to ensure a safe working environment. Use exhaust fans or open windows to remove fumes and prevent the buildup of heat.

- Cleanliness

Maintain a clean and organized workspace to prevent contamination and ensure optimal performance of the equipment.

- Lighting

The workspace should be well-lit to prevent eye strain and ensure accurate color reproduction.

- Noise control

Sublimation printing can be noisy, so consider using noise-cancelling headphones or other methods to reduce noise levels.

By following these tips, you can ensure a safe and optimal environment for sublimation printing, resulting in consistent and high-quality prints.

Troubleshooting Common Issues

Source: https://www.wavex.co.uk

Sublimation printing can be a complex process, and various issues can arise during the printing process. Here are some common issues and troubleshooting tips:

- Fading or dull colors

This can be due to low-quality ink, incorrect temperature or pressure settings, or an improper transfer process. Use high-quality ink and ensure correct settings, and consider using a coated transfer paper to enhance color vibrancy.

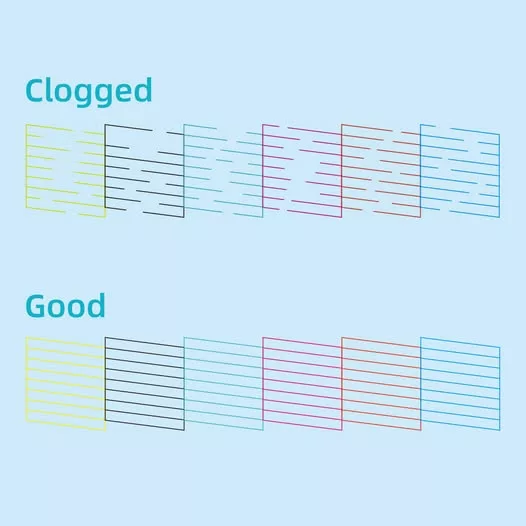

- Blurred or ghosted images

This can be due to improper pressure or the use of low-quality transfer paper. Adjust the pressure and consider using a coated transfer paper to reduce ghosting.

- Uneven or incomplete transfer

This can be due to improper pressure or temperature settings, or using the wrong type of transfer paper. Adjust the settings and use a coated transfer paper designed for your specific application.

- Substrate damage

This can occur due to overheating or over-pressing. Use the recommended temperature and pressure settings for your specific substrate, and avoid overheating or over-pressing.

- Substrate shrinkage or warping

This can be due to excessive heat or pressure during the transfer process. Use the recommended settings for your specific substrate, and avoid over-pressing or overheating.

- Paper jams

This can occur due to incorrect loading of the transfer paper. Make sure to properly load the paper and avoid overloading the sublimation printer.

Conclusion

Source: https://www.pinterest.com.au

In conclusion, achieving vibrant and long-lasting sublimation prints is possible with the right materials, techniques, and equipment. When looking for a reliable sublimation printer manufacturer, it’s important to consider factors such as print quality, speed, and durability. Sublimation printers from reputable manufacturers such as Epson, Sawgrass, and Ricoh offer excellent print quality and reliability.

Additionally, the emerging DTF printer technology and DTG printers can also produce high-quality sublimation prints on various fabrics. By following the tips and techniques outlined in this article and investing in the right equipment, you can create stunning sublimation prints that are both vibrant and long-lasting.