Product Highlights:

1. Hoson Control Board with Smart Monitoring

Equipped with a professional Hoson control board to ensure stable data processing and reliable long-term performance.

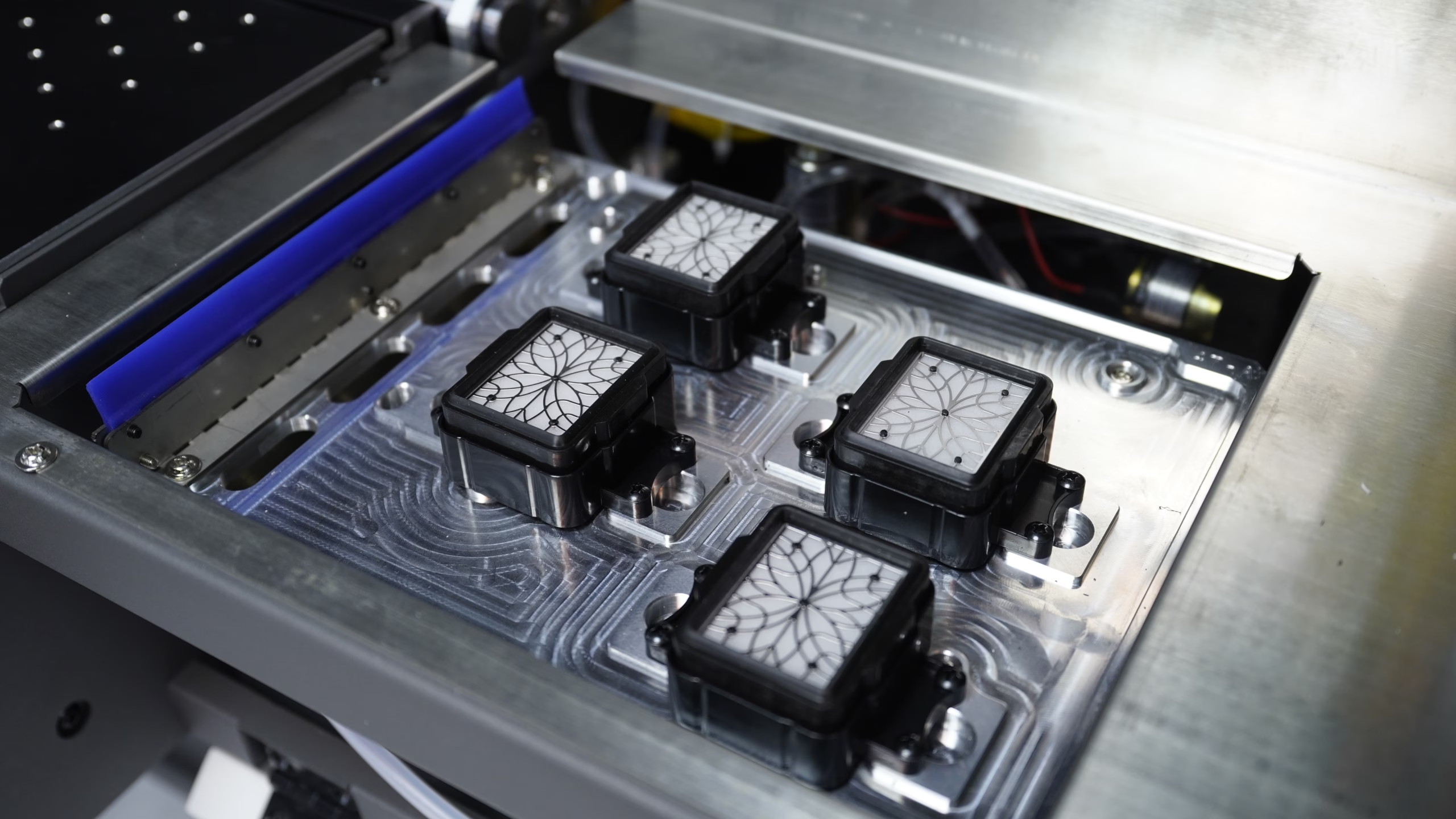

2. Advanced Ink & Printhead Protection System

Includes automatic humidification, motorized pressure roller lift, ink shortage alarm, waste-ink full alarm, and white ink circulation & stirring system to reduce printhead clogging and downtime.

3. Intelligent Integrated Powder Shaker

Powder shaker supports both Chinese and English languages, featuring automatic & manual powder spreading, vibration powder shaking, mesh belt conveyor, infrared heating tubes, cooling system, and sensor-based automatic take-up for smooth, continuous production.

4. 7-Inch Touchscreen Control Panel

Large, user-friendly touchscreen allows easy operation, real-time monitoring, and quick system adjustments.

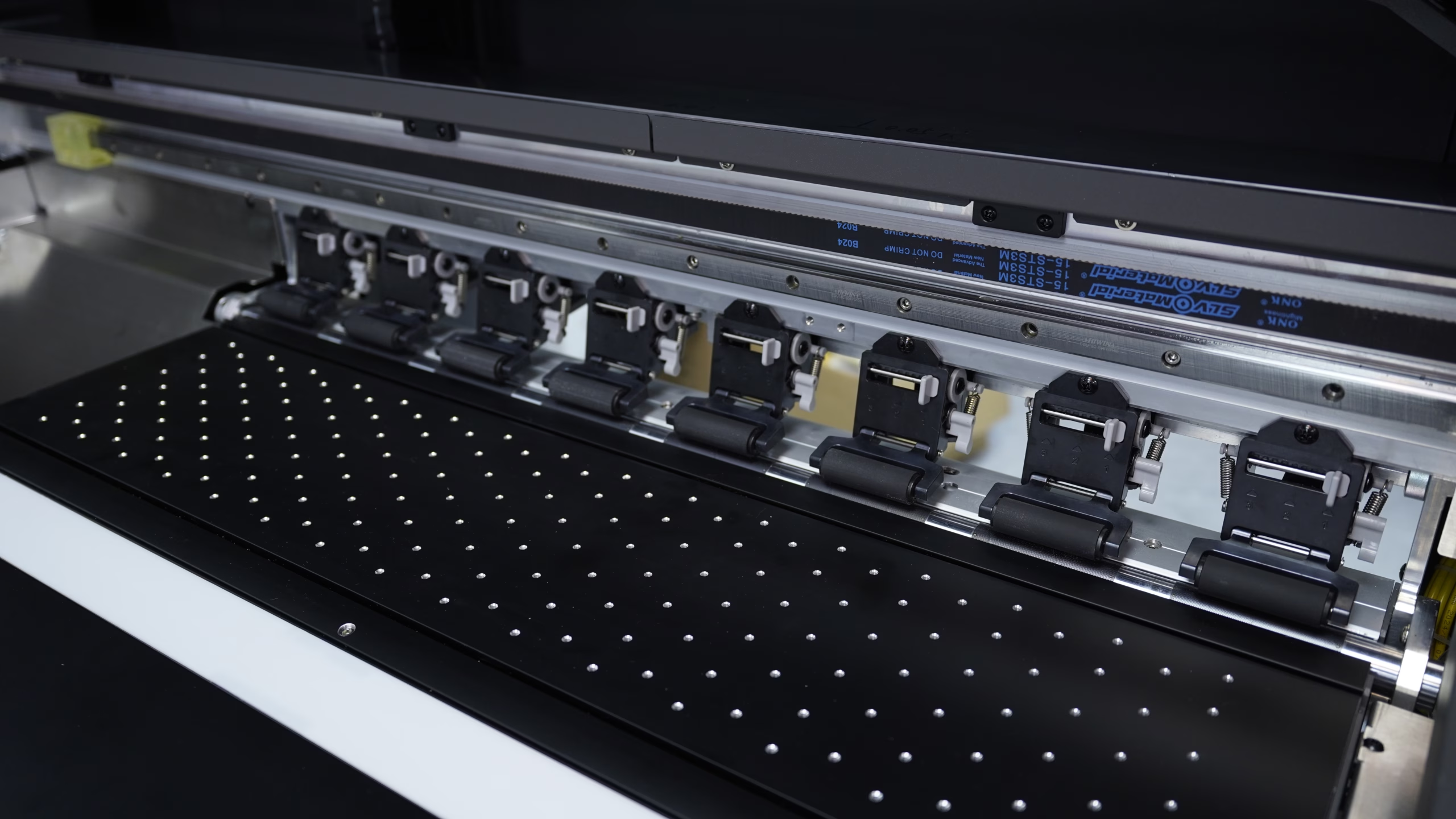

The electric pressure wheel lifting system provides precise control for adjusting pressure, ensuring smooth and consistent DTF printing on various substrates. This feature is essential for high-quality DTF prints, ensuring both a smooth process and long-term equipment durability.

The automatic moisturizing function keeps the printheads in optimal condition by maintaining the ideal ink viscosity. This minimizes clogging and ensures consistent print quality for longer periods, making it an excellent feature for maintaining high-quality DTF prints without interruptions.

The ink supply system features dual ink bottles integrated into the printer, designed to ensure a stable and consistent ink flow. These bottles are essential for continuous printing, especially during high-volume jobs, preventing interruptions and ensuring smooth operations in DTF printing for shirts and other custom products.

Stay ahead of your production needs with the ink shortage alarm. This feature alerts users when ink levels are low, preventing unexpected interruptions and ensuring smooth, uninterrupted DTF printing.

| Model | I3200-A1 |

|---|---|

| Ink Type | AQ ink |

| Max. number of colour inks | 4 colours |

| Number of nozzle | 3200 |

| Nozzle pitch /nozzle row | 1/300 inches |

| Nozzle Rows | 8 rows |

| Nozzle Resolution | 300npi/1 column 600npi/2 columns |

| Effective Print Width | 33.8 mm (1.33 inches) |

| Dimensions(LxWxH) | 69.1 x 59.4 x 35.6 mm |

| Weight | 82g |

| Model | 704E |

|---|---|

|

Printhead and Quantity |

4pcs Epson i3200-A1 |

| Printing Speed |

4Pass:27m²/h 6Pass:18m²/h 8Pass:13m²/h |

| Printing Color | CMYK+ CMYK+ W +W |

| Printing Width | 24" |

| Media Type | DTF Pet Film |

| RIP Software |

Standard with Printfactory ,Maintop, RIlN, PhotoPrint, CADlink for Optional |

|

Temperature/ Humidity |

Temperature: 20-30 °C, Humidity: 45%-65%RH |

| Power / Voltage | 1.6KW;220V/110V;50HZ/60HZ |

| Machine Size | L1740*W910*H1610mm |

| Packing Size | L1820*W880*H850mm |

| Net Weight | 162KG |

| Gross Weight | 200KG |

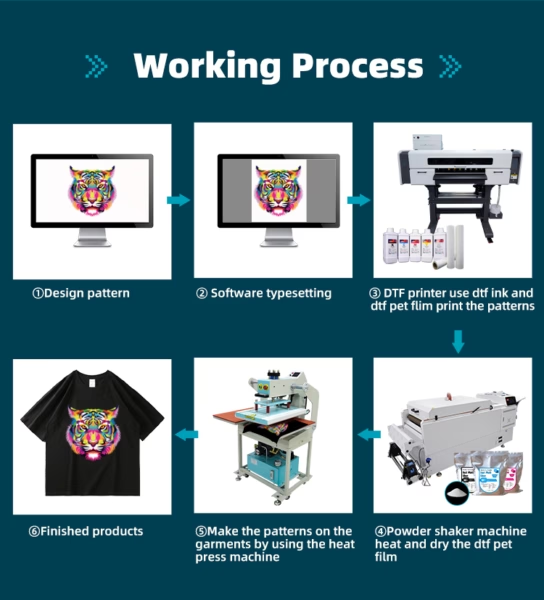

Use various design software to design spot color channels.

Use RIP software, color + spot color are RIP out.

DTF Fluorescent printing, dusting, drying the entire process of integrated operation processing, automatic winding.

The printed PET film will be cut manually or cut by cutting machine, and then pressed by hot press, and the film will be finished after tearing.

Q1: What level of production is this 24 inch DTF printer for?

A: It is designed for high-volume commercial production with strong speed and output stability.

Q2: Why use 4 Epson I3200-A1 printheads?

A: The 4-head configuration significantly increases printing speed and improves white ink coverage.

Q3: What industries is this printer suitable for?

A: Apparel factories, custom garment suppliers, and professional DTF printing service providers.

Q4: Is it compatible with automatic powder shakers?

A: Yes. It works seamlessly with industrial powder shaker and dryer systems.

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Printing Width

Productivity

Printhead

Dimension

Learn more about our DTF, DTG, sublimation printers, and consumables.

Learn more about our DTF, DTG, sublimation printers and consumables.