Fabric printing has emerged as a vital aspect in various industries, satisfying the increasing demand for high-quality fabric prints that are not only vibrant but also durable. In this blog post, we aim to compare two prominent fabric printing methods – sublimation printing and heat transfer printing. By delving into the intricacies of these methods, we intend to provide valuable insights that will assist readers in selecting the ideal fabric printer manufacturer for their specific needs.

What is Sublimation Printing?

Before finding the best printer for sublimation and heat transfer, let’s look at the differences between them to figure out which one is suitable for you. Sublimation printing is a popular method for creating high-quality, vibrant, and long-lasting prints on various materials. It utilizes the process of sublimation, which is the transition of a substance from a solid to a gas without passing through the liquid phase. This unique printing technique offers several advantages over traditional heat transfer methods, making it a preferred choice for many industries, including sports apparel and customized merchandise.

How does Sublimation Printing Work

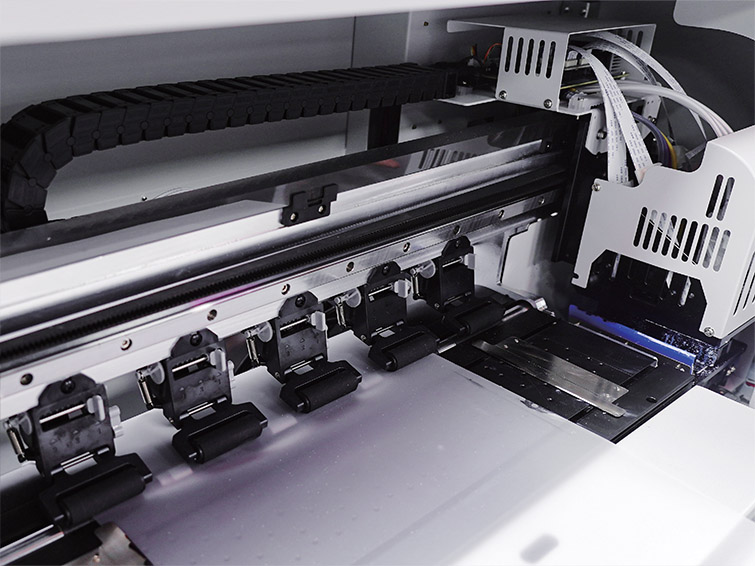

It involves several steps that result in vivid, durable prints. Firstly, the desired image or design is printed on a specialized sublimation paper using sublimation ink. Unlike regular inkjet printing, sublimation ink is specifically formulated to convert from a solid to a gas when heated, without leaving any residue on the paper.

Next, the printed sublimation paper is placed on top of the desired material, such as polyester fabric or coated ceramics. The entire setup is then subjected to high heat and pressure using a heat press machine. This combination of heat and pressure causes the sublimation ink to undergo a phase change and transform into a gas.

As the ink converts into a gaseous state, it permeates the material’s surface, bonding with its fibers or coating. This results in a permanent, long-lasting print that is resistant to fading, cracking, or peeling. The process is highly efficient, as the gas particles can penetrate even the tiniest crevices, creating a full-color and detailed print.

Advantages of Sublimation Printing

One of the major advantages of sublimation printing is the vibrancy of the prints it produces. Because the sublimation ink becomes part of the material instead of merely sitting on the surface, the colors appear more vibrant and true-to-life. Additionally, the prints retain their brightness and sharpness even after multiple washes, making them ideal for sports apparel, which often endures frequent laundering.

Furthermore, sublimation printing offers incredible durability. The prints are resistant to fading, making them suitable for products that are exposed to harsh environments or UV light, such as outdoor signage or beach towels. The prints are also highly flexible and stretchable, allowing them to maintain their integrity even on garments that undergo frequent movements or stretching.

Application of Sublimation Printing

Except for using sublimation printers for shirts, sublimation printing extends to a wide range of industries. Sports apparel, including jerseys, uniforms, and activewear, greatly benefit from the vibrant and durable prints that sublimation offers. Customized merchandise, such as mugs, phone cases, and textiles, can also be enhanced with sublimation printing, allowing businesses to create unique and personalized products for their customers.

What is Heat Transfer Printing?

Heat transfer printing has emerged as a popular alternative method for fabric printing, offering versatility and convenience. This process involves transferring designs onto fabric using heat and pressure, resulting in vibrant and durable prints. In this section, we will dive into the intricacies of heat transfer printing, its variations, benefits, limitations, and the industries that commonly utilize it.

How does Heat Transfer Printing Work

Starts with a transfer paper that contains the desired design or pattern. This paper is printed using specialized ink that can withstand high temperatures. Once the design is printed, it is placed face down onto the fabric and subjected to heat and pressure, causing the ink to transfer onto the fabric. This method allows for precise and detailed prints, making it suitable for intricate designs and patterns.

Heat transfer printing comes in various forms, each offering unique characteristics and applications. One popular variation is sublimation heat transfer, which involves using heat to convert dye particles into a gas that bonds with the fabric fibers. This method ensures long-lasting prints with vibrant colors and excellent durability. Another variation is plastisol heat transfer, which uses a type of plastic ink that is heat cured onto the fabric, creating a smooth and opaque design.

Benefits of Heat Transfer Printing

It‘s ease of use and requires minimal equipment and can be done on-demand, making it suitable for small-scale production or personalized prints. Additionally, heat transfer printing allows for efficient color reproduction, ensuring accurate and consistent results. However, it is important to note that heat transfer prints may be prone to color fading over time, especially when exposed to frequent washing and excessive heat.

Application of Heat Transfer Printing

The versatility of heat transfer printing makes it a popular choice in various industries. In the fashion industry, it is commonly used for customizing garments, adding unique designs or logos. Heat transfer printing also finds applications in the home decor industry, enabling the creation of personalized textiles, such as cushions, curtains, and bedding. Furthermore, this method is extensively used in the sports apparel industry to produce team uniforms and event merchandise.

Sublimation Printing vs. Heat Transfer in Brief

When choosing between sublimation printing and heat transfer, it’s crucial to consider factors such as material type, design complexity, and desired finish quality, as each method offers unique advantages and drawbacks.

| Sublimation Printing | Heat Transfer | |

| Process | Uses heat to move ink from paper to fabric in a gaseous form, resulting in an infusion that won’t wash out. | Uses heat to transfer a design from paper onto the fabric. |

| Print Quality | Provides vibrant and highly detailed prints that won’t fade or crack over time. | Can result in a relatively good print quality but may fade or crack over time, and the image may feel heavy on the fabric. |

| Durability | High, since the dye is infused into the fabric itself. | May not be as durable, as the image lay on top of the material rather than being infused into it. |

| Comfort | Very comfortable on the skin, as the print is part of the fabric. | The print can be slightly heavier and less comfortable. |

| Versatility | Can be used on a range of materials including polyester and other synthetic materials. | Ideal for printing on cotton, silk or nylon. |

| Color Range | Can achieve a wide range of colors and complex designs. | Color range can be slightly limited depending on the process and materials used. |

| Cost | Higher upfront costs due to the needed equipment and substrates, but lower ongoing costs. | Lower upfront costs, but higher ongoing costs due to the need for transfer papers and inks. |

| Application | Used in printing on polyester or other synthetic fabrics. Ideal for colorful and complex designs. | Commonly used for printing on cotton and other natural fiber fabrics. Best for simple designs with limited colors. |

Factors to Consider When Choosing a Fabric Printer

Print Quality

The foremost factor to consider is the print quality provided by the fabric printer manufacturer. Look for a fabric printer manufacturer that offers high-resolution printing, vibrant colors, and sharp images. Request print samples to evaluate the visual appeal and clarity of the prints.

Printing Technology

Two common fabric printer options are sublimation printer and heat transfer. Understand the pros and cons of each method and determine which one aligns better with your specific requirements. Some manufacturers may specialize in one technique, so choose accordingly.

Durability

Consider the durability of the prints, especially if the fabric will be exposed to frequent washing or outdoor elements. A reliable fabric printer manufacturer will use high-quality inks and materials that withstand multiple washes and maintain colorfastness.

Versatility

Evaluate the versatility offered by the fabric printer manufacturer. Can the printer handle different fabric types? Can it print on a wide range of sizes and shapes? Choose a manufacturer that provides a solution allowing you to maximize your creativity and cater to diverse client requirements.

Ease of Use

Operating a fabric printer should be smooth and hassle-free. Look for a manufacturer that provides user-friendly software and clear instructions. Additionally, inquire about technical support and how easily you can obtain assistance in case of any issues.

Speed and Production Capacity

Consider the production speed and capacity of the fabric printer. If you have high-volume printing requirements, ensure that the manufacturer can meet your demand without compromising print quality. Also, evaluate their turnaround time for orders, as this can impact your business’s efficiency.

Cost and Return on Investment

Determine the affordability of the fabric printer and assess its long-term value. Compare prices among different manufacturers, while also considering factors like maintenance, supplies, and operational costs. A higher upfront investment may be justified if the fabric printer offers superior performance and higher profitability in the long run.

Conclusion

The blog post has shed light on the key differences between sublimation printing and heat transfer printing, emphasizing the importance of understanding each method’s strengths and limitations. By determining their specific needs and preferences, readers can select an ideal fabric printer manufacturer. Ultimately, the aim is to provide guidance and assistance to those seeking to experience the vibrant and durable prints that fabric printing techniques offer.