Printing technology has come a long way, offering various methods to bring images to life on different surfaces. Two popular printing techniques in the industry today are UV DTF printing and DTF printing. While both methods offer impressive results, they have distinct features that set them apart. In this article, we will delve into the details of each printing method, compare their strengths and limitations, and provide guidance on selecting the right printing method for your needs.

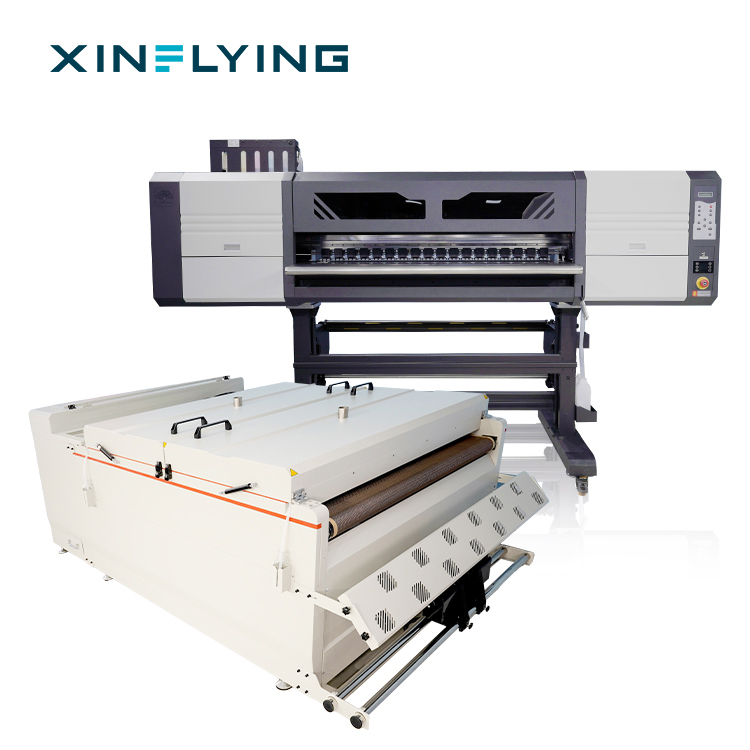

What is UV DTF Printing?

UV DTF printing, short for Ultraviolet Direct to Film printing, is a cutting-edge technology that allows for high-quality image transfers onto various substrates. Unlike traditional printing methods, UV DTF printing employs ultraviolet (UV) inks that are cured with UV light for exceptional durability and vibrant colors.

How to Use UV DTF Printer?

Step 1: Design on the RIP software

Firstly, prepare the artwork with RIP software on the computer. Then place the UV DTF A film on the platform of the UV DTF printer.

Step 2: Print on A Film

Prefill the cartridge with CMYK ink, white ink, and varnish to print your design on the UV DTF A film.

Step 3: Laminated B Film

Put the printed A Film into the laminating machine to stick it with the B Film.

Step 4: Place film on Products

Peel off the A film of the pattern and stick it on the item you want to print. Then slowly peel off the B film, and your product is finished.

Pros and Cons of UV DTF Printing

Advantages of UV DTF Printing

- High image quality and sharpness

UV DTF printing offers exceptional image quality with sharp details and vibrant colors. The UV inks have a wide color gamut, allowing for accurate color reproduction.

- Wide color gamut

UV DTF printing enables a wide range of colors to be printed on various substrates, resulting in rich and vibrant designs.

- Fast production time

Compared to traditional printing methods, UV DTF printing offers faster production times. The UV inks dry almost instantly, eliminating the need for extended drying periods.

- Ability to print on various substrates

UV DTF printing provides the flexibility to print on a wide range of materials, including fabrics, plastics, glass, and more. This versatility makes it an ideal choice for businesses looking to diversify their product offerings.

Limitations of UV DTF Printing

- Cost of UV inks and equipment

UV DTF printing requires specialized UV inks and equipment, which can be more expensive compared to traditional printing materials. Additionally, UV inks may have a shorter shelf life, requiring frequent replacements.

- Limited flexibility with certain materials

While UV DTF printing can be applied to various substrates, some materials may not be suitable due to their texture or surface composition. It is important to test print on different materials before committing to large-scale production.

- Maintenance and upkeep requirements

UV DTF printing equipment requires regular maintenance and upkeep to ensure consistent performance. This includes cleaning the printer heads and ensuring optimal conditions for UV curing.

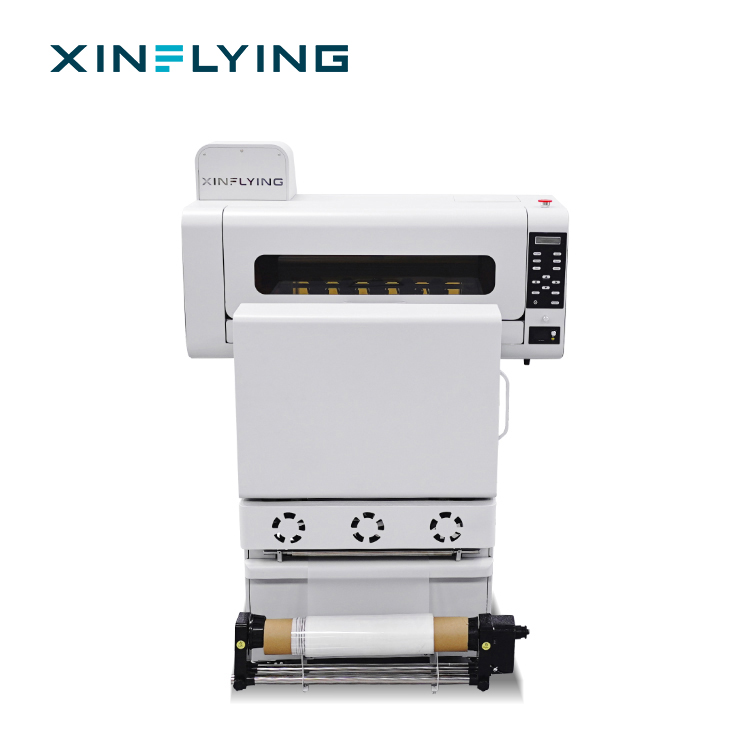

What is DTF Printing?

DTF printing, or Direct to Film printing, is a technique that involves printing designs onto a film using specialized inks, which are later transferred onto the desired substrate.

How to Use DTF Printer?

Step 1: Design on the RIP software

Similar to UV DTF printing, design the artwork using graphic design software, ensuring the desired design and image quality are achieved.

Step 2: Print on the PET film

Insert the PET film into the DTF printer trays and start printing. Then the design pattern will be transferred on it.

Step 3: Bond Ink with Powder

With a powder shaking machine, the DTF adhesive powder can spread evenly on the PET film and dry the graphics.

Step 4: Transfer Pattern on Textile

Place the DTF PET film on the top of substrate and transfer the design using heat press machine.

Pros and Cons of DTF Printing

Advantages of DTF Printing

- Cost-effective printing method

DTF printing is considered cost-effective, primarily due to its lower equipment and ink costs compared to UV DTF printing. This makes it accessible to small businesses and individuals looking to venture into the printing industry.

- Versatility in terms of compatible substrates

Like UV DTF printing, DTF printing allows for printing on various substrates, including fabrics, ceramics, plastics, and more. This versatility expands the range of products that can be produced using DTF printing.

- Ability to achieve vibrant colors and fine details

DTF printing can achieve vibrant and vivid colors, as well as fine details, making it suitable for intricate designs and complex artwork.

- Easy to use and clean

DTF printers are user-friendly, requiring minimal setup and maintenance. Additionally, the cleaning process is relatively simple, allowing for smoother operation and reduced downtime.

Limitations of DTF Printing

- Limited color gamut compared to UV DTF

While DTF printing can achieve vibrant colors, its color gamut may be narrower compared to UV DTF, limiting the range of shades and tones that can be reproduced.

- Longer production time

DTF printing may require additional steps for transferring the design onto the substrate, which can result in longer production times compared to UV DTF printing.

- May require additional steps for certain fabrics

Certain fabrics may require pre-treatment processes before printing with DTF inks. This can add complexity and time to the overall printing process.

UV DTF vs DTF: A Comparison

A. Print Quality Comparison

Resolution and sharpness

Both UV DTF and DTF printing can achieve high-resolution prints with sharp details. However, UV DTF printing may offer slightly sharper results due to the UV curing process, which enhances the ink permanence.

Color accuracy and vibrancy

UV DTF printing generally offers a wider color gamut, allowing for more accurate color reproduction and vibrant designs. DTF printing, while capable of vibrant colors, may have limitations in achieving certain shades and tones.

B. Types of Substrates

Fabric options

Both UV DTF and DTF printing can be used to print on various types of fabrics, including cotton, polyester, and blends. However, DTF printing may require additional steps or pre-treatment for certain fabrics to ensure optimal ink adhesion.

Printing on hard surfaces

When it comes to printing on hard surfaces such as glass, plastic, or ceramics, UV DTF printing is the preferred choice. The UV curing process ensures excellent ink adherence and durability on these surfaces.

C. Production Speed and Efficiency

UV DTF printing offers faster production times compared to DTF printing. The instant drying of UV DTF inks eliminates the need for extended drying periods, allowing for more efficient workflow.

D. Cost Comparison

UV DTF printing generally has higher upfront costs due to the specialized UV inks and equipment required. DTF printing, on the other hand, offers a more cost-effective entry point for those starting their

printing ventures.

E. Maintenance and Upkeep Requirements

Both UV DTF and DTF printing equipment require regular maintenance and upkeep. However, UV DTF printers may require more frequent cleanings and ink replacements due to the nature of UV inks.

DTF vs UV DTF, Which is Better?

| Type | DTF Printing | UV DTF Printing |

| Technology | Prints on a film that is then heat pressed onto the material. | Combines DTF technology with UV light to instantly cure the ink. |

| Ink | Uses CMYK+ white ink, printed on a clear PET film. | Uses UV ink, printed on a clear PET film. |

| Application | Cotton, polyester, cotton-poly blends, leather, nylon, and more. | Cotton, polyester, cotton-poly blends, leather, nylon, plastic, wood, metal, and even glass, and more. |

| Detail | Very high image quality and detail. | High image quality and detail, though UV process may slightly affect it. |

| Durability | Highly durable, but might not last as long as UV DTF. | Highly durable, UV process extends print longevity. |

DTF vs UV DTF Comparison Table

When to Choose UV DTF Printing

UV DTF printing is a suitable choice for businesses or individuals looking for high-quality prints with vibrant colors and sharp details. It is ideal for those who prioritize faster production times, have a need for printing on hard surfaces, and can accommodate the initial higher costs.

When to Choose DTF Printing

DTF printing is a cost-effective option for those starting out in the printing industry. It offers versatility in terms of compatible substrates and is relatively easy to use and maintain. DTF printing is recommended for those who prioritize cost efficiency, versatility in printing materials, and simplicity in operation.

Selecting the Right Printing Method

Desired Print Quality

Consider the level of image sharpness, color accuracy, and vibrancy required for your prints. UV DTF printing excels in these areas, while DTF printing offers a more cost-effective option with respectable print quality.

Type of Materials to Be Printed on

Take into account the diversity of substrates you plan to print on. If you anticipate a need for printing on hard surfaces or materials that may require pre-treatment, UV DTF printing is the better choice.

Production Quantities and Deadlines

If you have strict production deadlines or high-volume printing requirements, UV DTF printing’s fast production time may be more suitable. However, if production quantities are not a primary concern, DTF printing offers a capable alternative.

Available Budget

Consider your available budget for equipment, inks, and maintenance. UV DTF printing generally requires a higher upfront investment, while DTF printing presents a more cost-effective entry point. As well, it is important to choose a reliable fabric printer manufacturer.

Conclusion

In conclusion, UV DTF printing and DTF printing are two distinct methods that offer exceptional image quality and versatility.

UV DTF printing excels in terms of vibrant colors, sharp details, and the ability to print on various substrates, making it ideal for businesses with higher budget allocations and specific printing needs. DTF printing, on the other hand, provides a cost-effective entry point for small businesses and individuals seeking versatility, simplicity, and ease of use.

Ultimately, the choice between UV DTF printing and DTF printing depends on factors such as print requirements, substrate diversity, production quantities, and available budget. By considering these factors and understanding the strengths and limitations of each method, you can make an informed decision and achieve outstanding printing results.