Over the past few years, UV DTF printing has become one of the most popular digital printing technologies in the customization and manufacturing industries. But what exactly is a UV DTF Printer? How does the process work? And which type of businesses can benefit the most from this technology?

This article breaks down everything you need to know before choosing a UV DTF printer—from the printing mechanism to real-world applications and investment value.

What Is a UV DTF Printer?

A UV DTF Printer is a digital printer that uses UV-curable ink to print designs onto a special A Film, which is then transferred to a B Film (adhesive film) and finally applied to the surface of an object.

“DTF” stands for Direct to Film, meaning the design is printed on film—not directly on the object. Unlike traditional UV printers that require perfectly flat surfaces, UV DTF printing allows you to apply durable UV-ink stickers onto flat, curved, uneven, or textured items.

This breakthrough makes UV DTF printers extremely versatile, especially for businesses producing custom products.

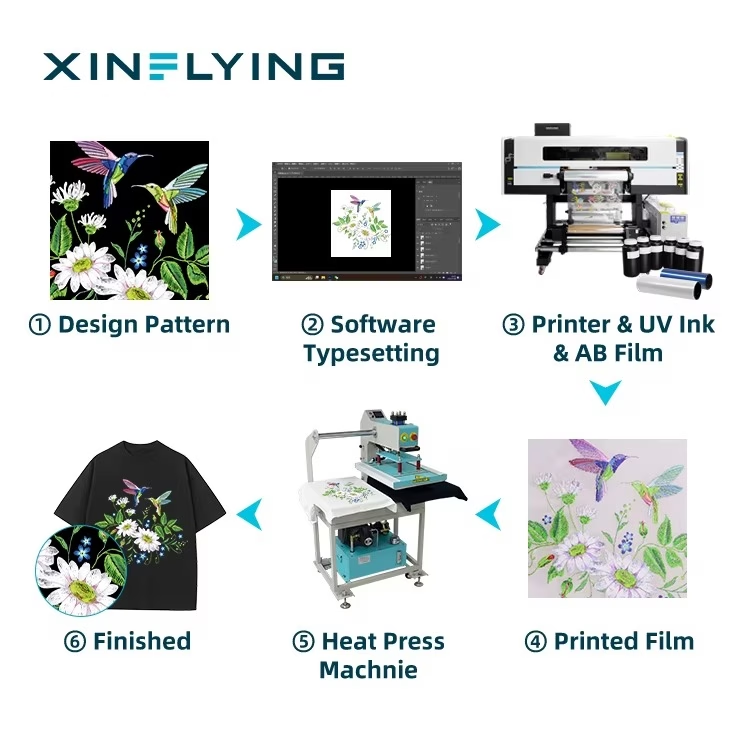

How Does the UV DTF Printing Process Work?

UV DTF printing follows a structured process that ensures precise, durable, and high-resolution results. Here’s the standard workflow:

Step 1: Print on A Film

The printer prints CMYK+White+Varnish in layers directly onto a transparent A Film.

Step 2: Apply B Film

The printed A Film is then laminated or pressed onto the B Film, a specially coated adhesive film.

Step 3: Peel and Apply

Once the A/B Film combination is ready:

- Peel the A Film away

- You get a ready-to-use UV DTF sticker

- Apply it to any surface and press firmly

No heating.

No pretreatment.

No curing lamps needed during transfer.

The sticker adheres instantly and permanently.

Why UV DTF Printers Are Transforming the Printing Industry

Below are the top benefits that make UV DTF one of the fastest-growing printing technologies worldwide.

1. Works on Nearly Any Surface

UV DTF prints can be transferred onto almost any material, including:

Rigid materials

- Glass

- Metal

- Wood

- Ceramic

- Acrylic

- Stone

Flexible materials

- Leather

- PU/PVC

- Vinyl

Special items

- Tumblers

- Bottles

- Laptops

- Phone cases

- Packaging boxes

- Home décor items

Because the UV DTF sticker acts as a bridge, you no longer need to worry about uneven surfaces or difficult shapes.

2. No Pretreatment, Heating, or Special Coatings Needed

Traditional UV printers often require:

- Flat surfaces

- Accurate height detection

- Dedicated coatings

- Skilled operators

But UV DTF printing eliminates all these barriers.

You simply print → laminate → apply.

This greatly reduces labor, time, and production complexity.

3. Strong Adhesion & Extremely Durable

UV DTF stickers feature:

- Scratch resistance

- Water resistance

- UV/fade resistance

- Chemical resistance

- 3D embossed texture from varnish layer

This makes the final products suitable even for:

- Daily use

- Outdoor environments

- Commercial-grade applications

4. Perfect for Small Batch, High-Mix Customization

UV DTF enables profitable low-quantity production, such as:

- 10 pieces of custom bottles

- 30 personalized mugs

- 100 custom packaging gifts

- One-off souvenir designs

This is ideal for businesses that rely on fast customization cycles.

Which Industries Benefit Most From UV DTF Printing?

Because of its flexibility and ease of use, UV DTF technology is widely adopted across many sectors.

1. Promotional & Gift Industry

UV DTF is perfect for:

- Corporate gifts

- Branded giveaways

- Event souvenirs

- Personalized merch

Companies love UV DTF because it supports small orders with fast turnaround.

2. E-commerce & Personalized Product Sellers

Platforms like Etsy, Shopee, Amazon, and Shopify are full of:

- Custom tumblers

- Personalized phone cases

- Name-tag gifts

- Accessories and ornaments

UV DTF enables sellers to create high-quality items without needing a factory.

3. Packaging & Branding

Ideal for:

- Cosmetic packaging

- Food packaging labels

- Luxury gift boxes

UV DTF stickers are waterproof and scratch-proof, making them suitable for retail shelves.

4. Home & Lifestyle Product Manufacturers

Applications include:

- Decorative tiles

- Glass panels

- Furniture ornaments

- Custom acrylic plaques

UV DTF adds value to interior products with minimal equipment requirements.

5. Small Custom Shops & Startups

With low start-up cost, simple workflow, and fast ROI, UV DTF printers are popular among:

- Print shops

- Makers studios

- Small gift customization stores

- Startups entering the customization market

Is a UV DTF Printer Worth It?

Based on industry trends, UV DTF printers offer:

- High profit margins

- Low learning curve

- Wide material compatibility

- Fast return on investment

- High durability prints

- Support for both mass and small batch production

If your business focuses on custom merchandise, personalized gifts, brand packaging, or surface decoration, a UV DTF printer can significantly upgrade your production efficiency and product value.