In a world where creativity knows no bounds, it’s essential to have the right tools to unleash your artistic visions. One such tool that has been making waves in the design industry is DTF printing. By converting your existing printers into DTF printers, you can take your designs to the next level and redefine what’s possible. In this article, we will explore the ins and outs of DTF printing, guiding you through the whole process with necessity. Get ready to revolutionize your printing game!

What is DTF Printing?

Before diving into the conversion process, let’s take a moment to understand what DTF printing is all about. DTF, which stands for Direct-To-Film printing, is a technique that allows for vibrant and high-quality prints on various substrates. Unlike traditional printing methods, DTF printing involves transferring the ink directly onto a special film, which is then heat-pressed onto the desired substrate. This innovative process ensures exceptional color vibrancy and sharp detailing, elevating your designs to new heights.

Choosing the Right Printer for DTF Conversion

Now that we have a grasp of DTF printing, it’s time to choose the right DTF printers for sale. Several printer models are suitable for DTF conversion, including popular and affordable DTF printer brands like Epson, Xinflying, Canon, and HP. However, factors such as types, print head technology, ink compatibility, and printer settings should be considered when selecting an affordable DTF printer. Researching and understanding the specifications of different printers will help you make an informed decision for the cheapest or commercial DTF printer.

Factors to Consider when Dtf printer for Beginners

If you are new to DTF transfers and looking to invest in a printer for this specific printing technique, there are a few key factors to consider. The right printer will play a crucial role in achieving high-quality, long-lasting prints for your DTF transfers. Here are some important points to keep in mind while choosing a DTF printer:

Printer Compatibility

Ensure that the printer you choose is compatible with DTF printing. While DTF technology is versatile and can work with various printer models, it is essential to select a printer that supports DTF ink and is capable of handling the required paper thickness.

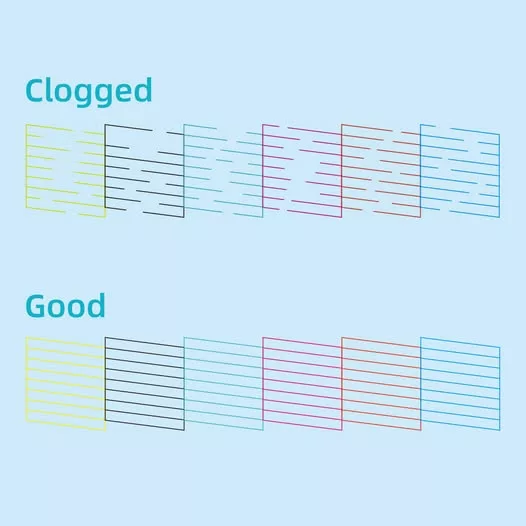

Resolution and Print Quality

DTF transfers rely on vibrant colors and fine details, so choosing a printer with a high resolution is vital. Look for printers that offer a resolution of at least 1440 dpi (dots per inch) for sharp and crisp prints that accurately reflect the design.

Ink System

DTF ink differs from traditional inkjet ink and plays a significant role in achieving optimum print quality. Look for printers that support DTF-specific ink and ensure that the ink system allows for easy maintenance, refilling, and color management.

Size and Media Handling

Consider the size of prints you intend to produce. If you primarily require smaller designs, a desktop-sized printer may suffice. However, if you plan on printing larger designs or batches of DTF transfers, investing in a printer with a larger print area and efficient media handling capabilities will be beneficial.

Easy Operation

As a beginner in DTF printing, opting for a printer that is user-friendly and easy to operate will help expedite your learning process. Look for printers that offer intuitive interfaces, straightforward settings, and good technical support to facilitate a smoother printing experience.

Durability and Longevity

It is essential to select a printer that is built to withstand continuous DTF printing and delivers reliable performance. Consider the printer’s durability, lifespan, and aftermarket support, as these factors will impact the long-term viability of your investment.

Gathering the Necessary DTF Printer Bundles

When it comes to DTF transfers, ensuring you have the right printer is essential for achieving high-quality results. To embark on this new printing technique, you will need to gather the necessary bundles to kick-start your DTF journey.

RIP Software

To optimize your prints and fine-tune the colors and overall quality, you will require a RIP (Raster Image Processor) software specifically designed for DTF printing. RIP software allows you to efficiently manage color profiles, adjust image settings, and ensure accurate color reproduction, enhancing the overall output quality of your prints.

DTF Printer

The most crucial component to start with is a printer specially designed for DTF transfers. Unlike standard inkjet printers, DTF printers are equipped with unique features that enable them to handle the specific requirements of the DTF process. These printers should have the ability to handle high-resolution images and provide excellent color saturation for vibrant prints.

DTF Ink

Alongside the appropriate printer, you will need the right type of ink for DTF transfers. DTF ink is formulated to adhere well to both the transfer film and the final print substrate, ensuring long-lasting and durable results. DTF ink typically comes in different vibrant colors, allowing you to create vivid and eye-catching designs.

DTF Transfer Film

The DTF transfer film serves as the carrier for the ink during the transfer process. It is important to select a high-quality and transparent film that can handle the ink saturation and adhere well to the garment or fabric. Keep in mind that different films may require specific ink formulations, so it’s crucial to choose the appropriate film compatible with your printer and ink

DTF Powder

Its primary role is to bond the ink to the fabric, ensuring a durable and vivid print. This powder comes in a finely ground form and exhibits strong adhesive properties when activated with a heated press.

Heat Press

In addition to the printer and ink, you will need a reliable heat press machine for transferring the DTF design from the film to the target material. A heat press applies both heat and pressure to ensure the ink effectively bonds with the substrate, resulting in a permanent, vibrant, and wash-resistant print. Look for a heat press that offers precise temperature and pressure controls for better control over the transfer process.

By gathering these necessary bundles, including a DTF printer, appropriate ink, heat press, DTF transfer film, and suitable RIP software, you’ll be equipped with the essentials to dive into the world of DTF transfers. Ensuring all these components work harmoniously together will greatly contribute to achieving professional and visually stunning results in your DTF printing journey.

Future Trends and Innovations in DTF Printing

As DTF printing continues to gain popularity, the industry is on the cusp of exciting trends and innovations. Emerging technologies, such as UV DTF printing, advancements in DTF ink formulations, and the integration of AI in print quality optimization, are set to revolutionize the industry even further. Keep an eye on these developments, as they will undoubtedly shape the future of DTF printing, offering new possibilities and pushing the boundaries of what’s achievable.

Conclusion

In conclusion, by venturing into the realm of DTF printing and converting your printers into powerful DTF machines, you open the door to endless creative opportunities. From the initial understanding of DTF printing to the step-by-step conversion guides, troubleshooting techniques, and maintenance tips, this article has equipped you with the knowledge and resources to embark on knowing what printers can be converted to DTF.